Microbial nutrient solution, simultaneous removing method and device for SO2 and NO2 in industrial waste gas

A nutrient solution and microbial technology, applied in the field of environmental governance, to achieve the effects of reducing secondary pollution, simple operation process, and reduced operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

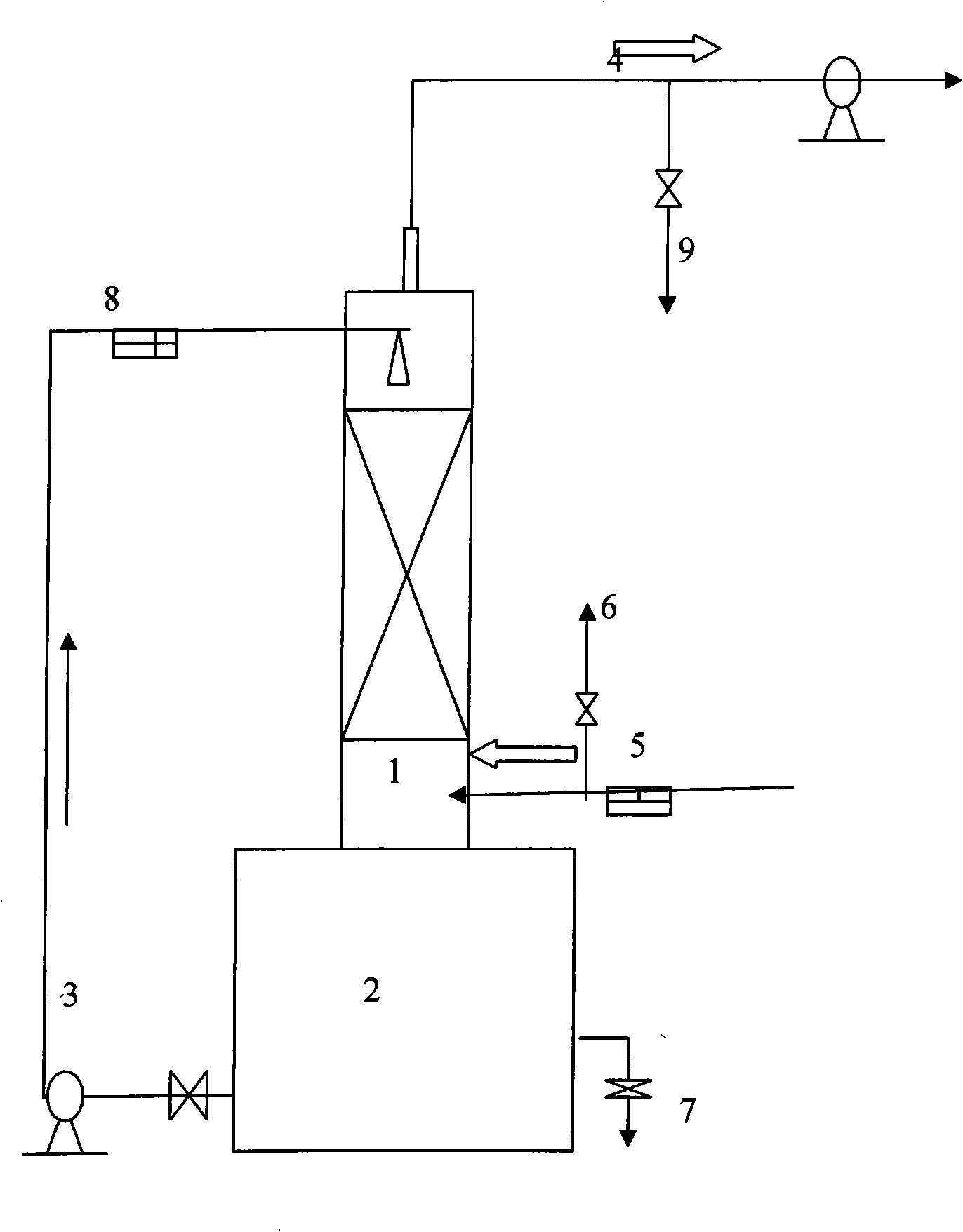

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: the composition and content of nutrient solution formula are as follows:

[0040] Na 2 SO 4 0.4g / L; (NH4) 2 SO 4 0.4g / L; Na 2 S 2 o 3 1.0g / L; K 2 HPO 4 1.1g / L; KH 2 PO 4 0.9g / L; KNO 3 1.8g / L; NaHCO 3 0.7g / L; MgSO 4 ·7H 2 O 0.8g / L; sodium lactate 4.0g / L; yeast extract 0.8g / L.

[0041] Using the above-mentioned microbial nutrient solution to reduce SO in industrial waste gas 2 and NO X The method for synchronous removal comprises the following steps:

[0042] (1) Soak the tower with the landfill leachate rich in desulfurization bacteria and denitrification bacteria for 1 to 2 days, and keep the temperature inside the tower at 25°C and the pH value at 7.5 under anaerobic environment

[0043] (2) Drain the landfill leachate, add microbial nutrient solution, start the pump, and when the nutrient solution is exhausted, drain the effusion and add fresh nutrient solution;

[0044] (3) After the surface of the filler is evenly covere...

Embodiment 2

[0048] Embodiment 2: the composition and content of nutrient solution formula are as follows:

[0049] Na 2 SO 4 0.5g / L; (NH4) 2 SO 4 0.5g / L; Na 2 S 2 o 3 0.9g / L; K 2 HPO 4 1.0g / L; KH 2 PO 4 1.0g / L; KNO 3 2.0g / L; NaHCO 3 0.5g / L; MgSO 4 ·7H 2 O 0.6g / L; sodium lactate 3.5g / L; yeast extract 1.0g / L.

[0050] Using the above-mentioned microbial nutrient solution to reduce SO in industrial waste gas 2 and NO X The method for synchronous removal comprises the following steps:

[0051] (1) Soak the tower with the landfill leachate rich in desulfurization bacteria and denitrification bacteria for 1 to 2 days, and keep the temperature in the tower at 35°C and the pH value at 8 in an anaerobic environment;

[0052] (2) Discharge 1 / 2 of the volume of landfill leachate, add and remove the same volume of microbial nutrient solution as the landfill leachate, start the pump, and when the nutrient solution is exhausted, drain the effusion and add fresh nutrient sol...

Embodiment 3

[0057] Embodiment 3: the composition and content of nutrient solution formula are as follows:

[0058] Na 2 SO 4 0.6g / L; (NH4) 2 SO 4 0.6g / L; Na 2 S 2 o 3 0.8g / L; K 2 HPO 4 0.9g / L; KH 2 PO 4 1.1g / L; KNO 3 2.2g / L; NaHCO 3 0.5g / L; MgSO 4 ·7H 2 O 0.6g / L; sodium lactate 3.0g / L; yeast extract 1.2g / L.

[0059] Using the above-mentioned microbial nutrient solution to reduce SO in industrial waste gas 2 and NO X The method for synchronous removal comprises the following steps:

[0060] (1) Soak the tower with landfill leachate rich in desulfurization bacteria and denitrification bacteria for 1 to 2 days, and keep the temperature inside the tower at 30°C and the pH value at 7.5 in an anaerobic environment;

[0061] (2) Discharge part of the landfill leachate, add and remove the same volume of microbial nutrient solution as the landfill leachate, start the pump, and when the nutrient solution is exhausted, drain the effusion and add fresh nutrient solution...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com