Use of electrothermal alloy in six-side top high-temperature high-pressure synthetic cavity

A technology of high temperature and high pressure synthesis and electrothermal alloy, which is applied in the process of applying ultra-high pressure, and can solve the problems of easy breakage, ineffectiveness, short-circuit synthesis of graphite tubes and graphite composite rods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] (1) Directly wind the electric heating alloy thin skin around the insulating tube instead of the graphite heating tube to synthesize diamond:

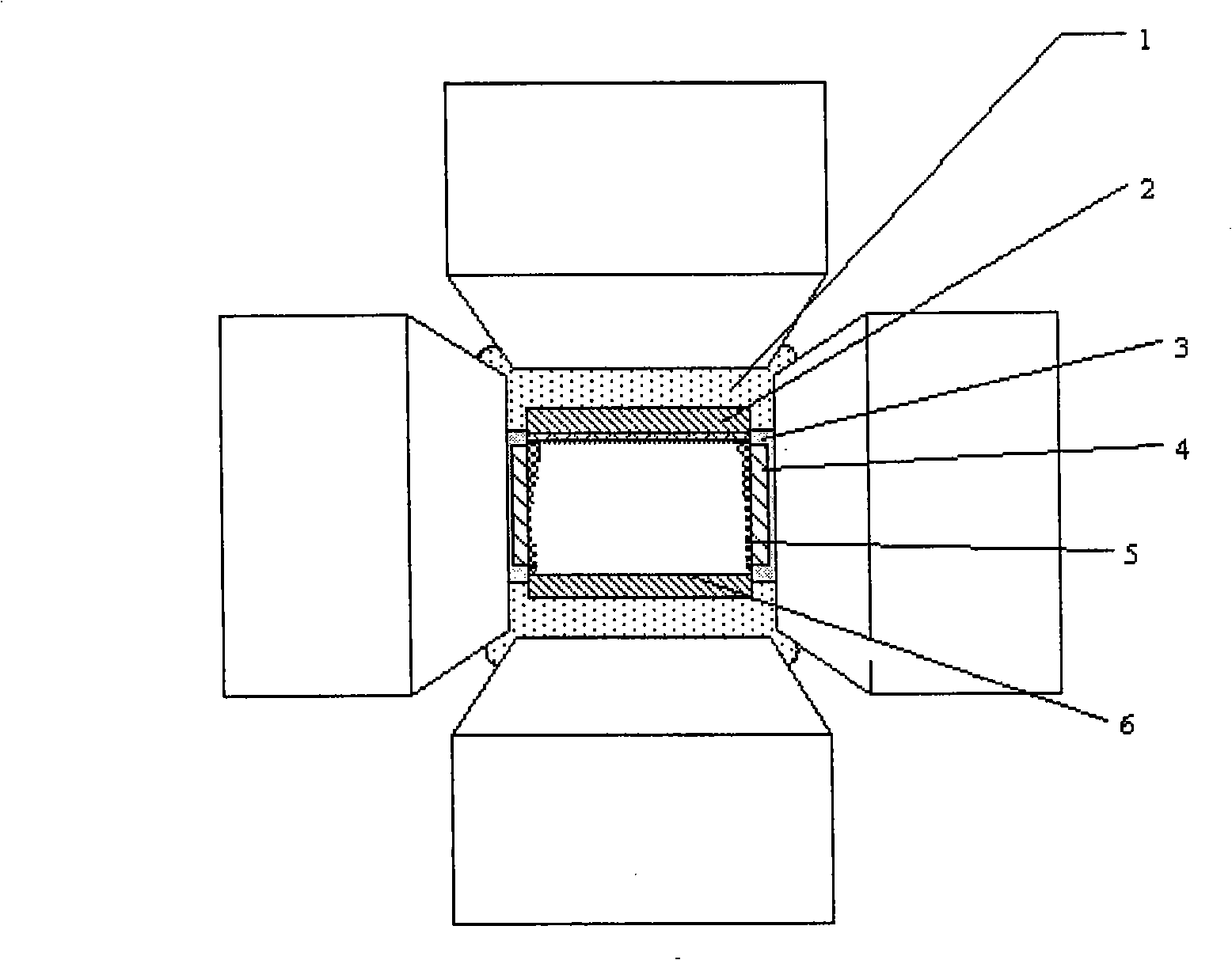

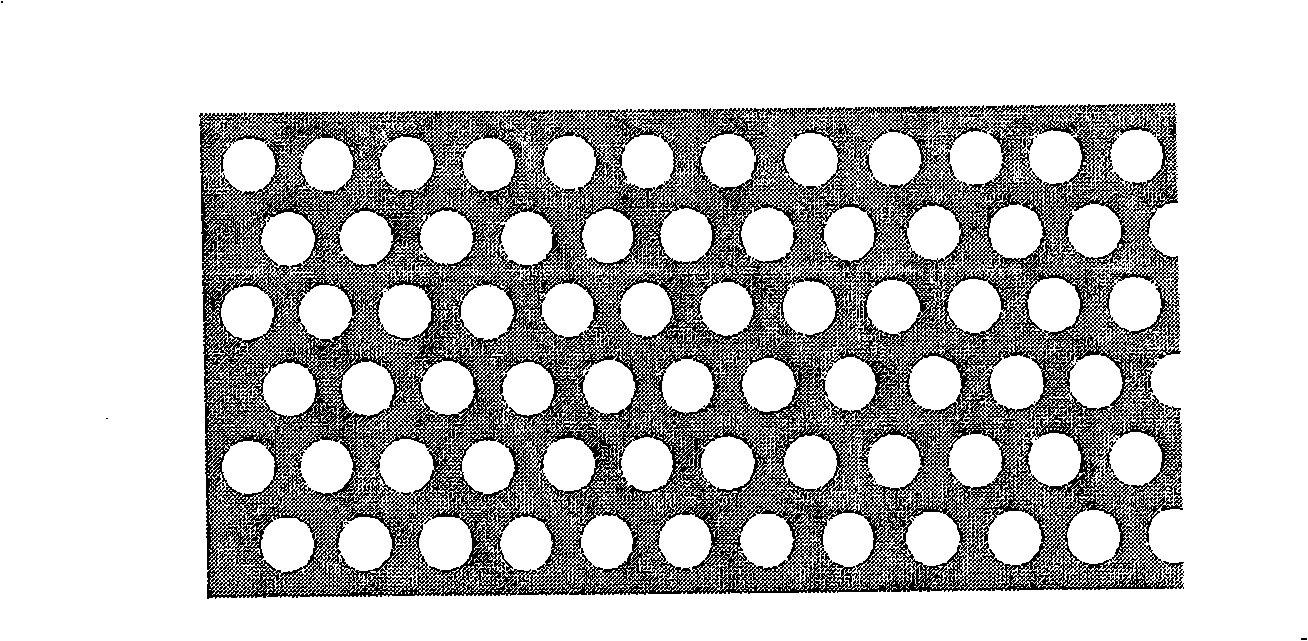

[0019] The electric heating alloy (the composition is listed in Table 1, the three types of electric heating alloys have similar effects in diamond synthesis, therefore, only the relevant synthesis data of the No. 1 component alloy are listed below) into a thin skin with a thickness of 0.10 mm, and cut Cut into a certain width and length. Replace the graphite heating tube in the indirect heating synthetic diamond assembly. The assembly drawing is as follows:

[0020] Table 1 Examples of electric heating alloy components

[0021] Sample number

Iron%

aluminum%

1

70.2

22.5

6.2

0.5

2

66.7

26.5

6.0

0

1.8

3

69.7

25.0

4.5

0.5

0.3

[0022] The h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com