Vacuumable gel for decontaminating surfaces and use thereof

一种凝胶、表面活性剂的技术,应用在可抽吸凝胶领域,能够解决裂纹未被很好地控制、很难抽吸或擦拭来除去、粘度和干燥率不能始终很好地得到控制等问题,达到尺寸均匀性提高、提高分离的能力的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0073] Prepare a kind of including AEROSIL (8wt%), 0.1M HNO 3 and 1.5M H 3 PO 4 reference gel.

[0074] In this example, the conditions of use for drying the gel were as follows: 22°C, 40% relative humidity.

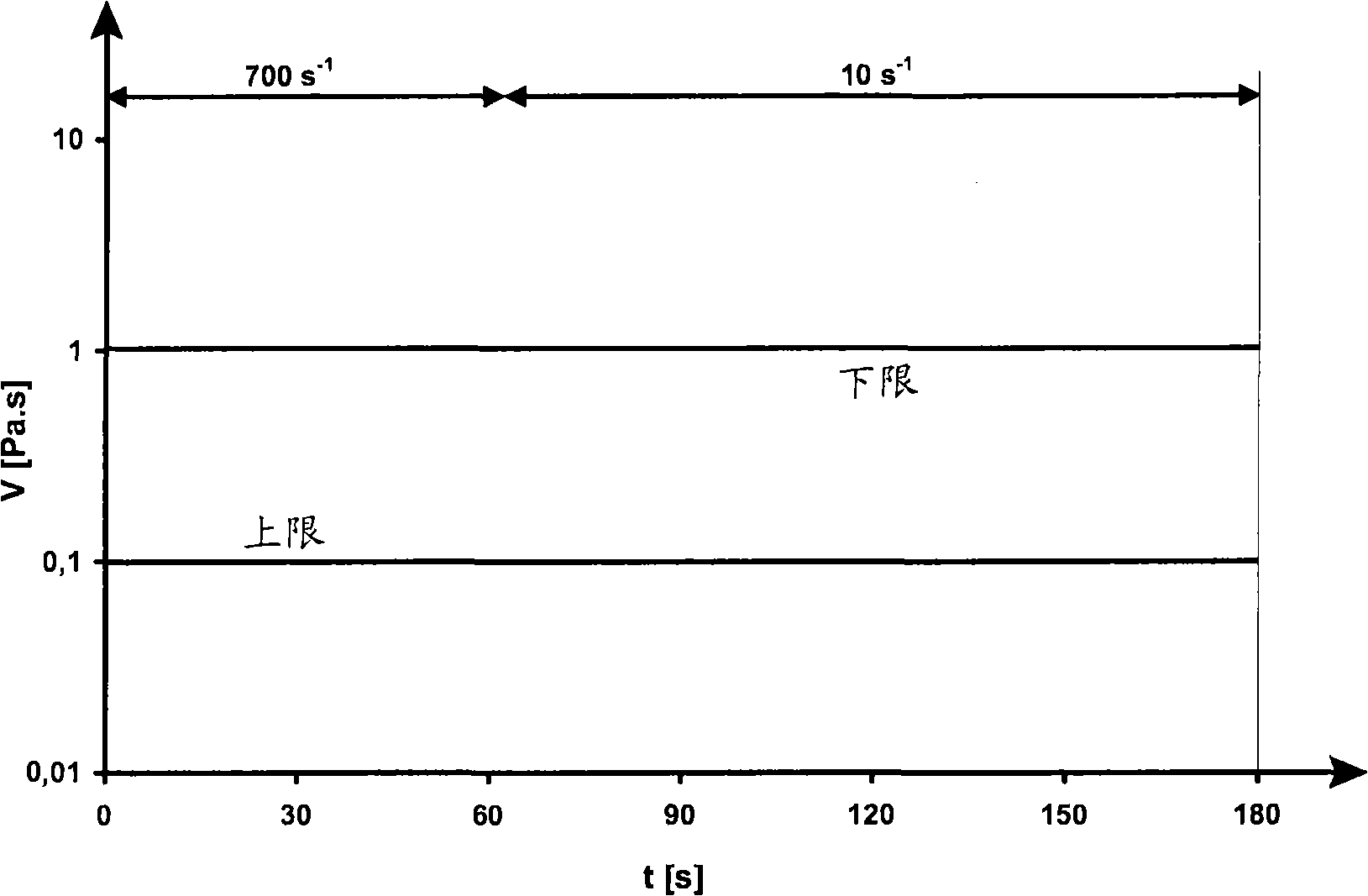

[0075]In order to be able to spray the gel at low pressure, the viscosity limit is set to high shear (cisaillement, shear stress) (700s -1 ) under 100mPa·s. To obtain a gel that does not flow down the wall, at low shear (10s -1 ) at a viscosity higher than 1 Pa·s is required.

[0076] This can be done by figure 1 The rheogram is shown for illustration.

[0077] The viscosity of the gel must preferably be in the blank area of the figure, which can ensure the convenient use of the gel.

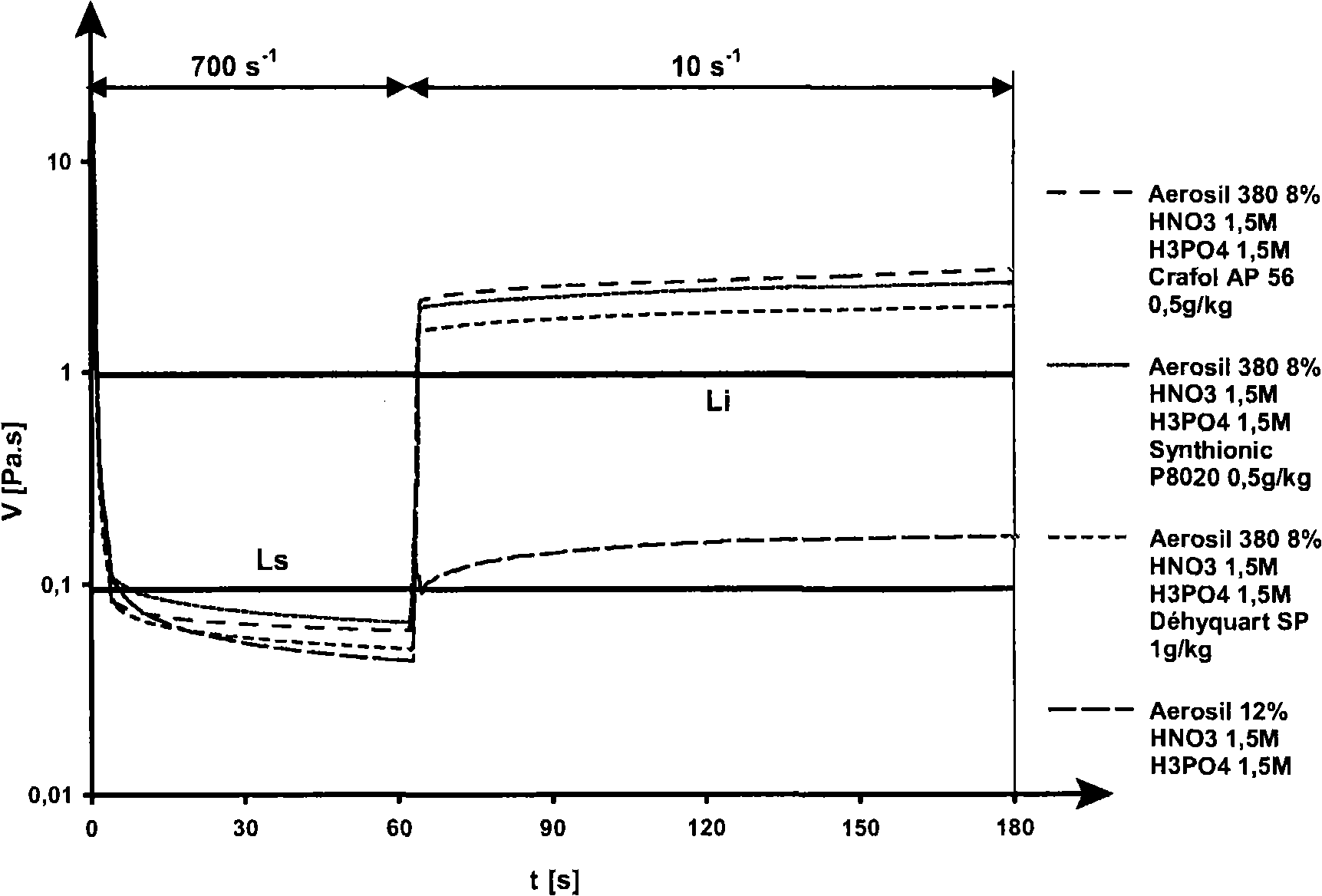

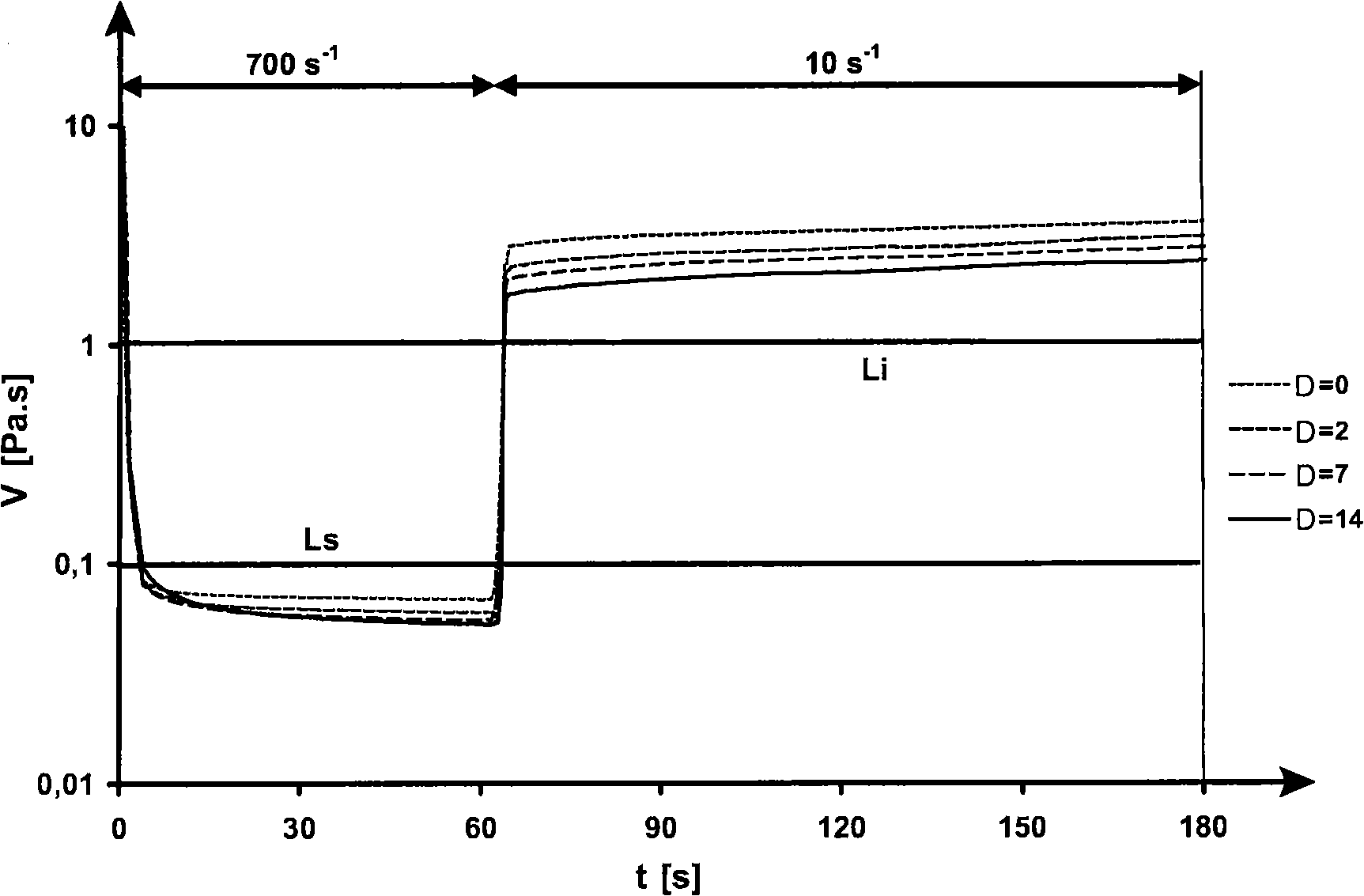

[0078] The addition of small amounts of surfactants according to the invention allows optimization of the rheological properties of the prior art pumpable gels.

[0079] figure 2 Rheograms showing various acidic gels containing various surfactants (CRAFOL AP56, SYNTHIONICP8020...

example 2

[0093] Example 2: Effect of Surfactants on Gel Drying Time

[0094] In this example, SYNTHIONIC or ANTAROX (trademark) were tested in an amount of 0.1 wt% in a 1.5M to 3.5M phosphoric acid gel containing 10 wt% AEROSIL 380 (trademark).

[0095] In this gel, surfactant molecules are placed at the gel / air and silica / solution interfaces to minimize contact with water molecules. Thus, the surface of the gel is covered with surfactant molecules that can slow down or facilitate evaporation.

[0096] Regarding the effectiveness of the gel, Figure 4 Corrosion kinetics obtained on aluminum samples treated with acid gel, acid gel containing 2 g / kg of ANTAROX (trade mark) and acid gel containing 2 g / kg of SYNTHIONIC (trade mark) are shown.

[0097] The operating conditions are as follows: 22°C, 40% relative humidity.

[0098] The experimental results show that the presence of SYNTHIONIC and ANTAROX (trademark) increases the drying time of the acid gel by about 30 minutes to 1 hour. ...

example 3

[0100] Example 3: Effect of Surfactants on Cracks

[0101] Figure 5 is a visual comparison between a gel according to the invention (left) and a gel according to the prior art, ie without surfactant (right), which are allowed to dry under the same conditions of temperature, humidity and time Photo.

[0102] An oxidizing gel film containing 0.5M cerium and 3M nitric acid was prepared on a stainless steel sample (right in the photo).

[0103] 1 g / kg of wetting surfactant SYNTHIONIC P8020 was added to the components of the gel (left sample).

[0104] On the left, the surface of the gel containing surfactants obtained more uniform cracks. The size of the solid residue was monodisperse (1 mm to 2 mm) (invention).

[0105] This avoids the formation of larger solid residues (5mm to 7mm) of polydisperse size observed in the image on the right, which would be more difficult to recover as they are more cohesive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com