Defect mending method and structure

A defect repair and defect technology, applied in the field of repair structure, can solve problems such as damage, material oxidation, poor conductivity and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

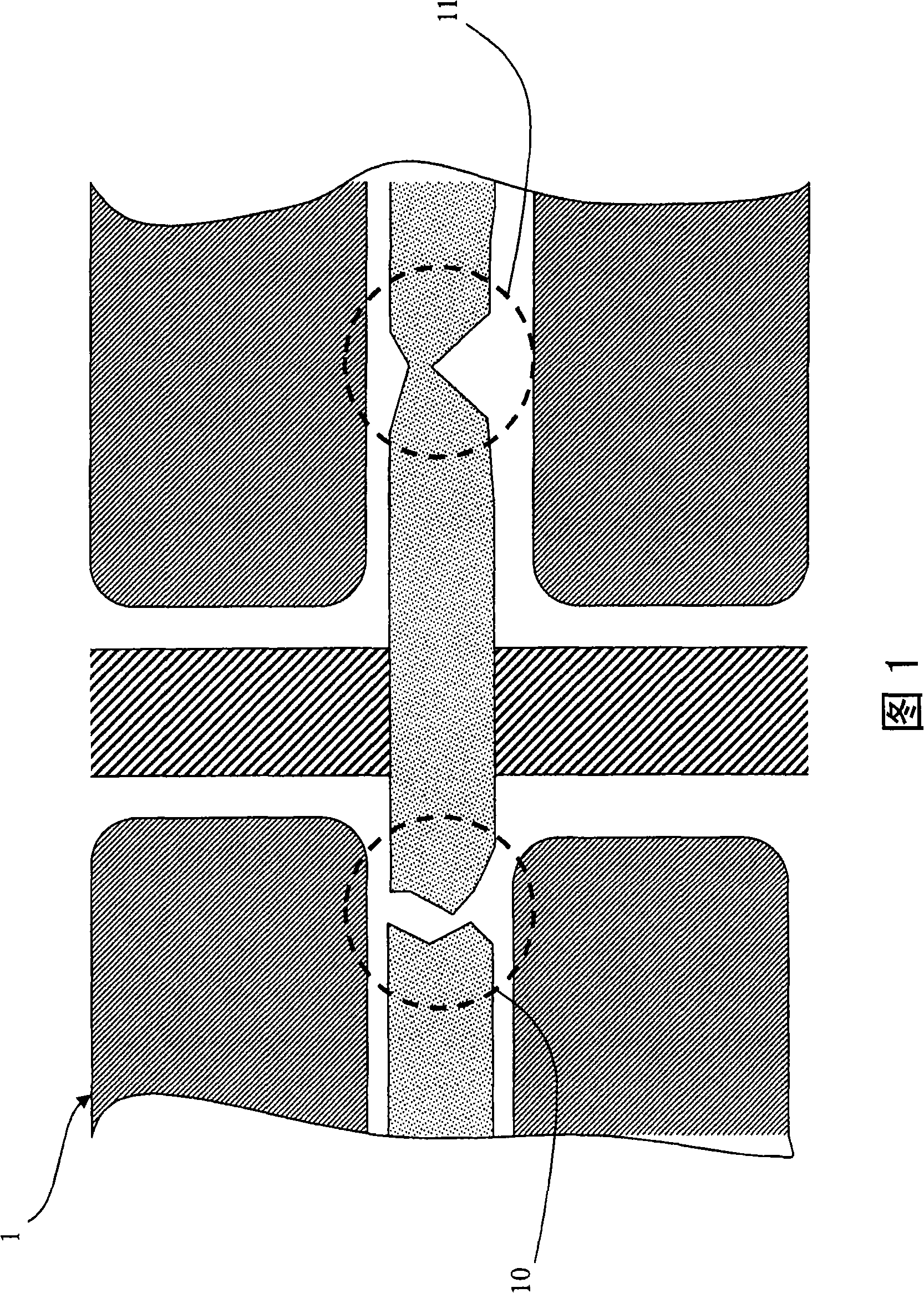

Image

Examples

Embodiment Construction

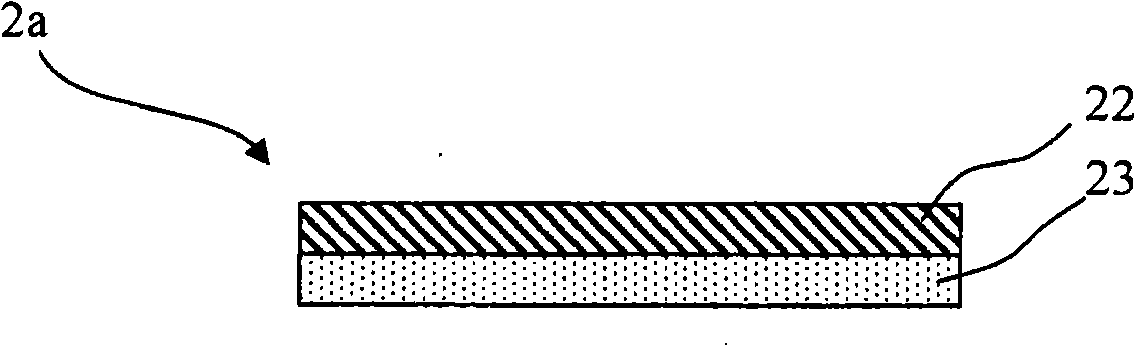

[0112] see Figure 2A As shown, this figure is a schematic diagram of the first embodiment of the defect repairing structure of the present invention. The defect repairing structure 2 a has a conductive adhesive layer 23 , and a repairing material layer 22 is formed on the conductive adhesive layer 23 . The material properties of the conductive adhesive layer 23 are conductive and adhesive, so that the repairing material layer 22 can be easily attached to the defective circuit 21 . The conductive adhesive layer 23 is silver glue in this embodiment. The repairing material layer 22 is a metal material layer, and the metal material can be selected from tungsten, gold, silver, copper, silver glue or molybdenum, but not limited thereto.

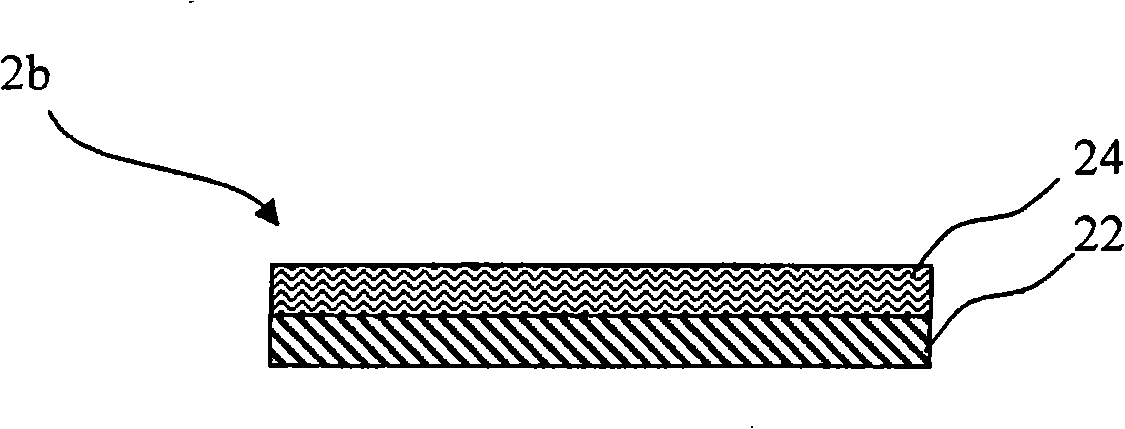

[0113] see Figure 2B As shown, this figure is a schematic diagram of the second embodiment of the defect repairing structure of the present invention. The defect repairing structure 2 b has a repairing material layer 22 , and an intermediate l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com