Construction method for reinforcing heat supply pipeline and tee joint

A technology for heating pipes and construction methods, applied in excavation, soil protection, infrastructure engineering, etc., can solve problems such as increasing pipe wall thickness, increasing construction cost, fatigue deformation, etc., to reduce stress damage, increase engineering cost, Effects suitable for implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

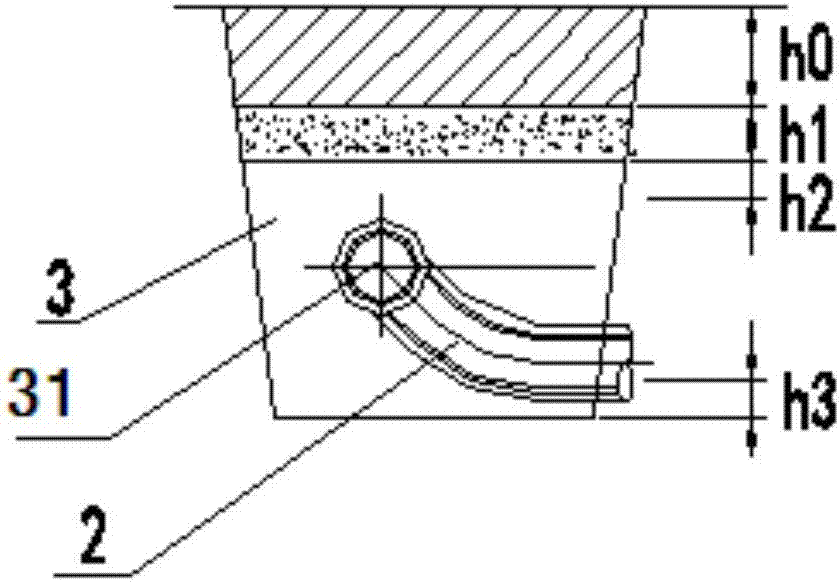

[0026] Embodiments of the technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solutions of the present invention more clearly, and therefore are only examples, rather than limiting the protection scope of the present invention.

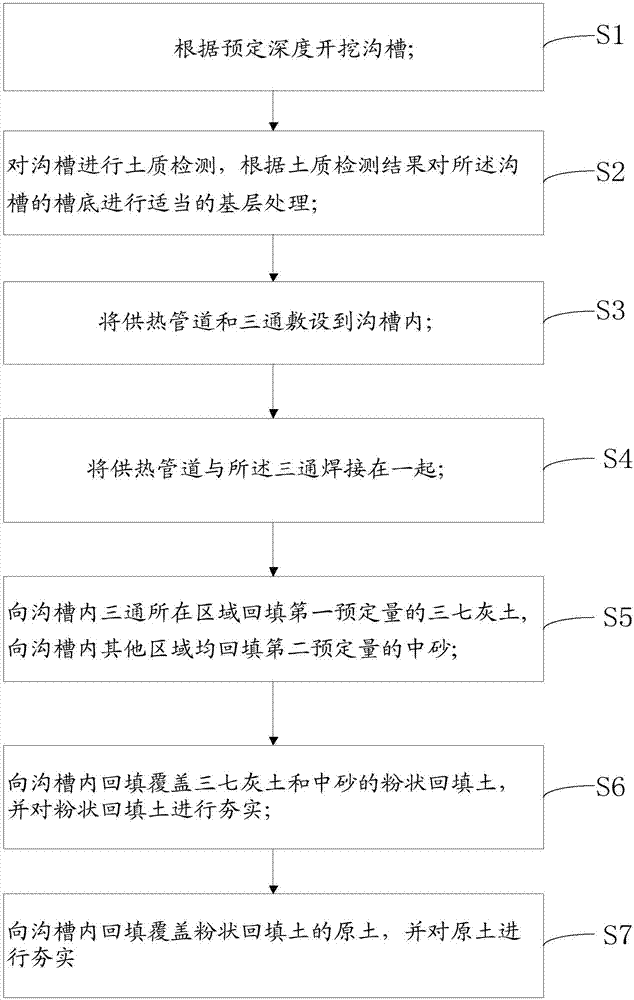

[0027] figure 1 It is a flowchart of a construction method for reinforcing heating pipes and tees according to an embodiment of the present invention, such as figure 1 As shown, the construction method includes the following steps:

[0028] S1. Excavating the trench according to the predetermined depth;

[0029] S2. Carry out soil quality inspection to the trench, and carry out appropriate grass-roots treatment on the bottom of the trench according to the soil quality inspection result;

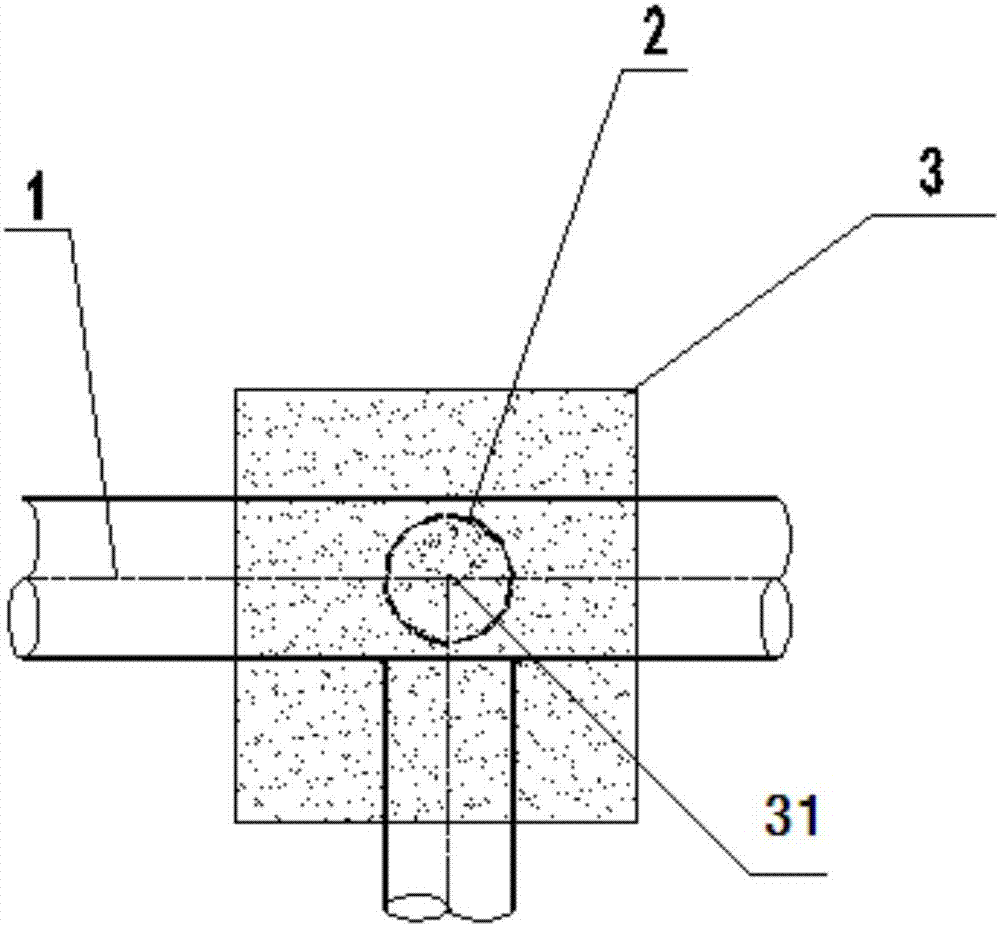

[0030] S3. Laying the heating pipe 1 and the tee 2 into the trench;

[0031] S4, welding the heating pipe 1 and the tee 2 to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com