A Model Test Device for Staggered Failure of Tunnel Crossing Active Fault Zones that Can Apply Triaxial Stress

A model test device, a technology of triaxial stress, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of unfavorable tunnel support construction, inability to excavate tunnels for model samples, and small thickness of shear layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

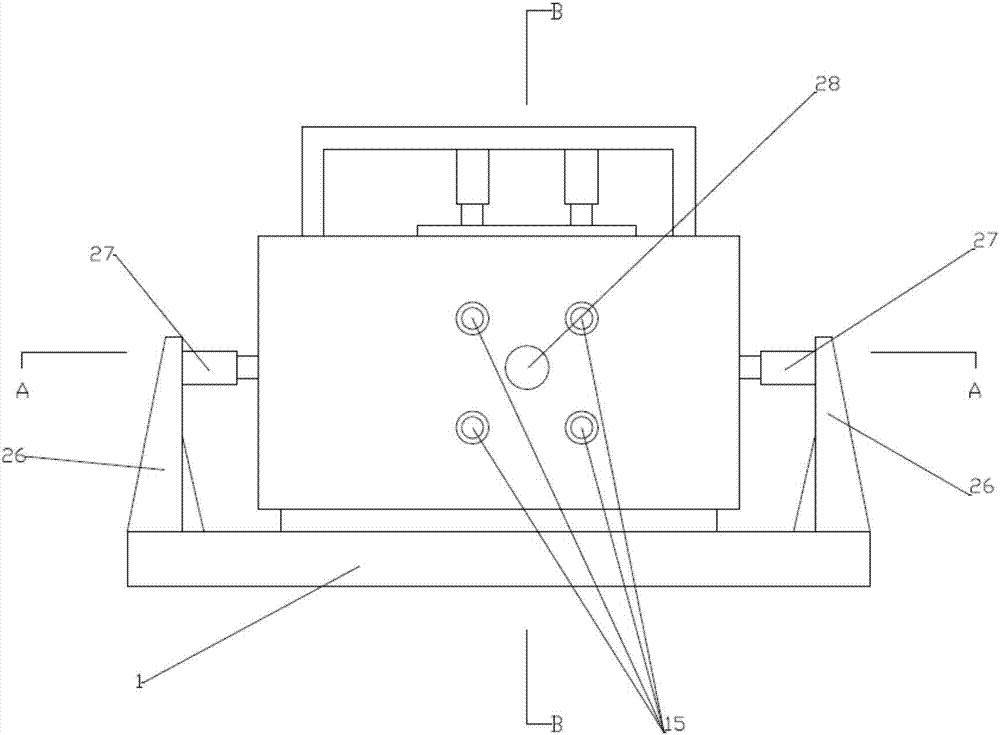

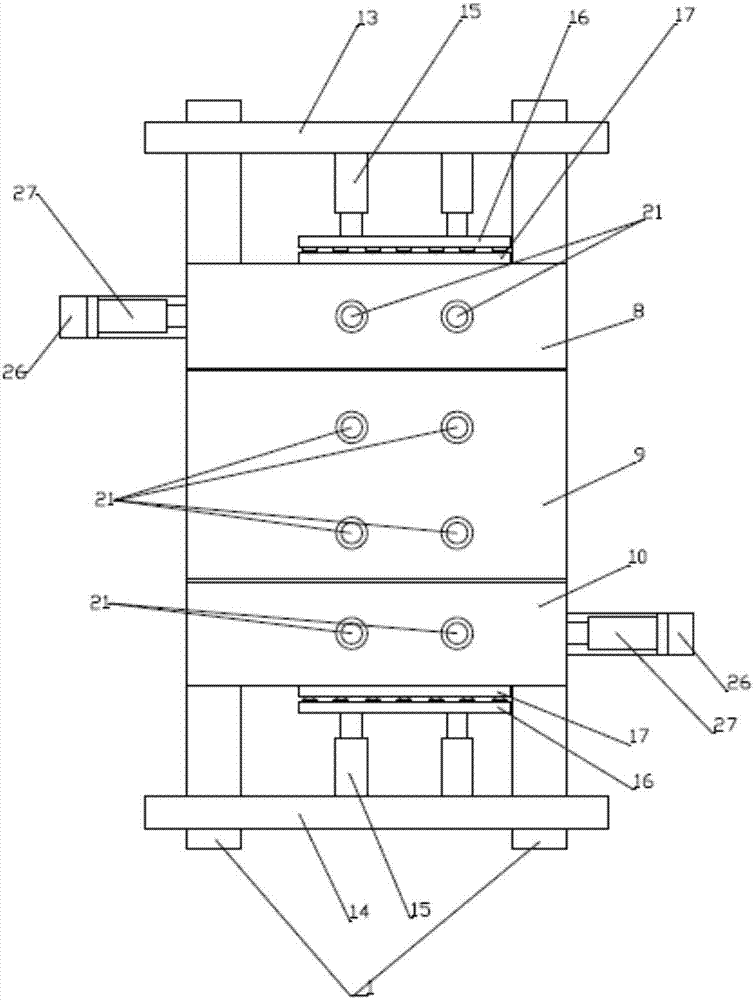

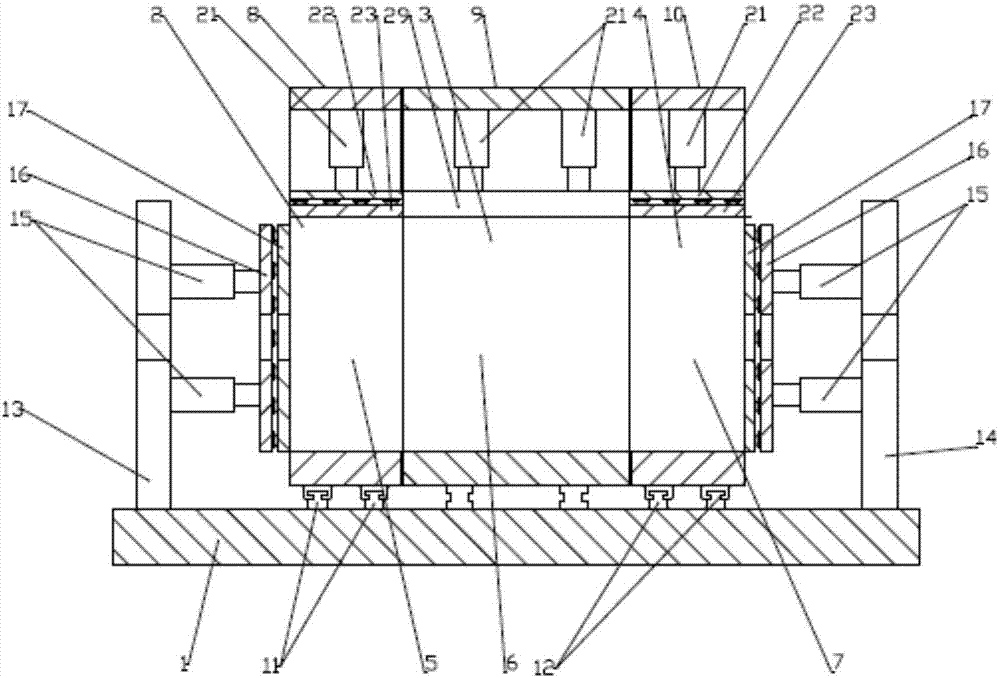

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0021] A model test device for the dislocation failure of a tunnel passing through an active fault zone that can apply triaxial stress in this embodiment includes a base 1, and the base 1 can be composed of two guide rails arranged side by side with intervals; the base 1 of this embodiment The upper part is longitudinally arranged side by side with a rectangular first test chamber 2, a second test chamber 3 and a third test chamber 4 for loading samples. The first test chamber 2 has a longitudinal rear side wall and a transverse left side. The wall and the vertical upper side wall are respectively connected to the output ends of the first longitudinal loading device, the first lateral loading device and the first vertical loading device, so as to realize the triaxial loading of the sample 5 in the first test chamber 2 ; the third test...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com