Connecting method with powder dust separating device, vertical type invert exhaust-heating boiler and exhaust pipeline

A technology for waste heat boiler and dust separation, which is applied in the steam generation method using heat carrier, furnace, waste heat treatment, etc., which can solve the problems of large exhaust gas resistance, affecting the normal operation of cement kiln, long pipeline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

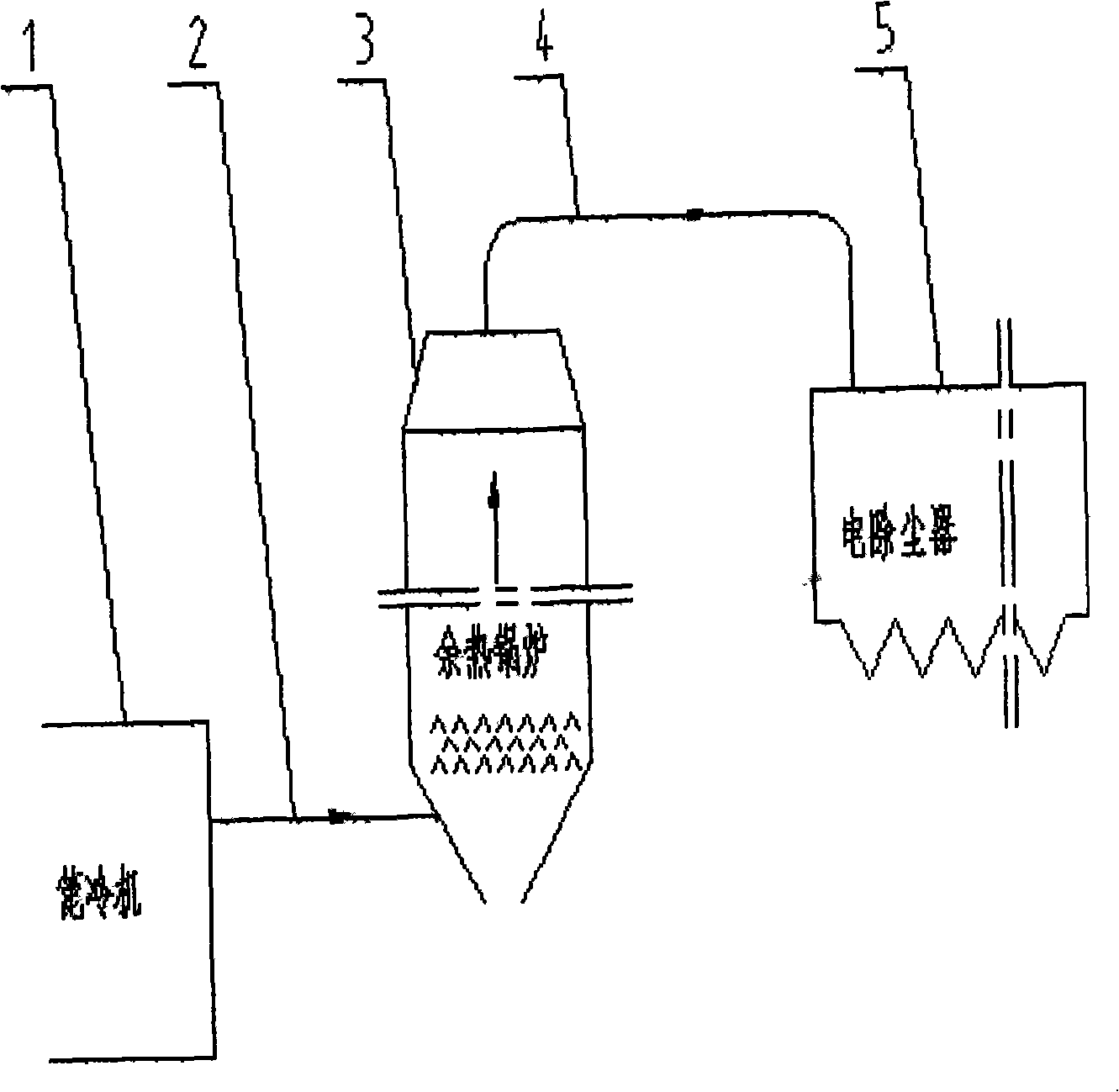

[0016] The exhaust gas extracted from the middle part of the grate cooler ① at the kiln head of the cement production line enters the vertical inverted waste heat boiler ③ with a dust separation device through an inlet connecting pipe ② connected by pipes. After absorbing heat through the waste heat boiler ③, the low-temperature exhaust gas passes through the connecting pipe ④Enter the dust collector ⑤, and the exhaust gas after the treatment reaches the standard is discharged into the atmosphere.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com