A logistics vehicle with a fully active suspension system and its application

An active suspension and logistics vehicle technology, applied in the field of logistics vehicles, can solve problems such as cost or structural limitations, the volume of the vehicle body cannot be reduced, and the vibration reduction effect is not good, and achieves a simple structure, reduces axle load transfer, and saves energy. consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The device of the present invention will be described in further detail below in conjunction with the accompanying drawings.

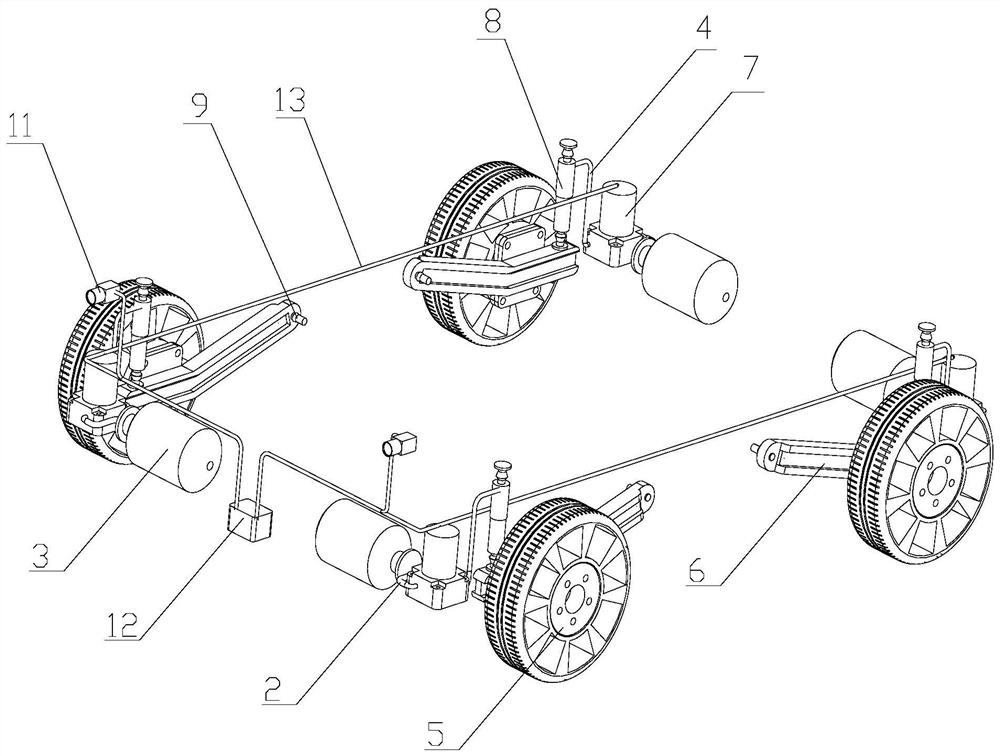

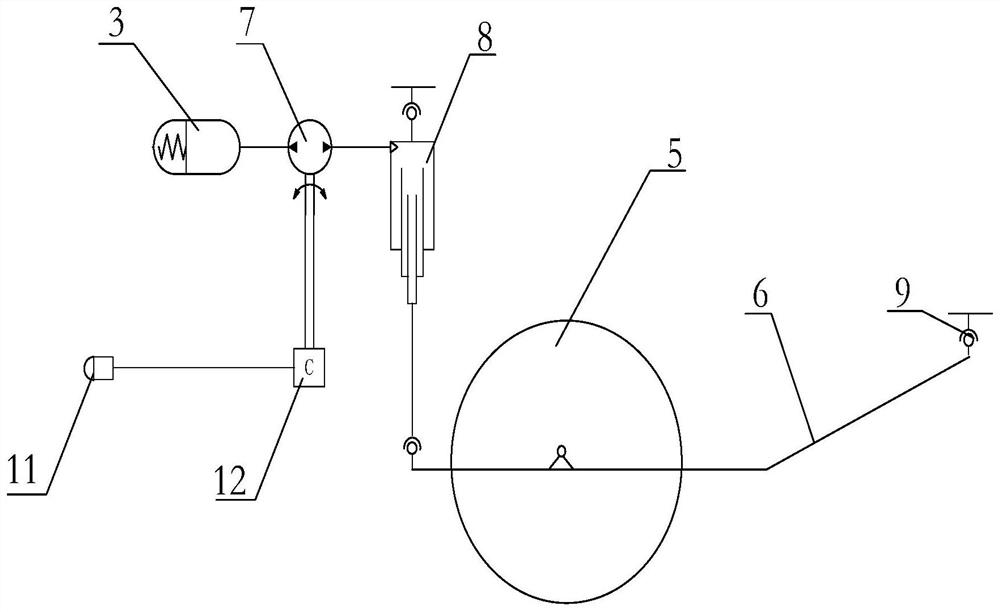

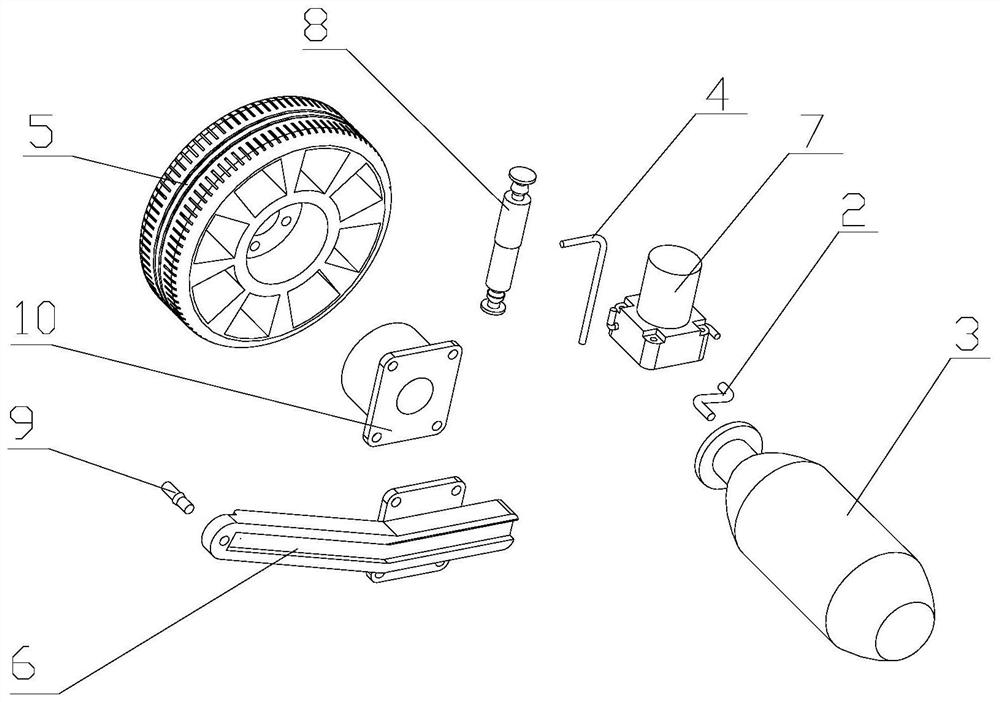

[0018] Such as figure 1 As shown, the present invention provides a kind of full active suspension system, comprises accumulator 3, electronic gear pump 7, power cylinder 8, swing arm 6, control system 12 and steering knuckle 10; The front end of described steering knuckle 10 is Cylindrical, the rear end is a plate structure; the hub motor stator of each wheel is fixedly connected to the cylinder of the steering knuckle 10, and the plate structure of the steering knuckle 10 is fixedly connected to the side of one end of the swing arm 6, The upper surface of one end of the swing arm 6 connected to the wheel hub is connected to the power cylinder 8 through a ball joint 9, and the other end of the swing arm 6 is connected to the vehicle body through a ball joint 9. The high pressure oil of the power cylinder 8 and the electronic gear pump 7 The out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com