Multilayer piezoelectric element and ejector using this

A piezoelectric element, lamination type technology, which is applied in the manufacture/assembly of piezoelectric/electrostrictive devices, fuel injection devices, electrical components, etc., and can solve problems such as insufficient improvement, change in displacement, and occurrence of cracks. and other problems, to achieve the effect of suppressing the change of displacement, suppressing stress concentration, and suppressing the occurrence of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

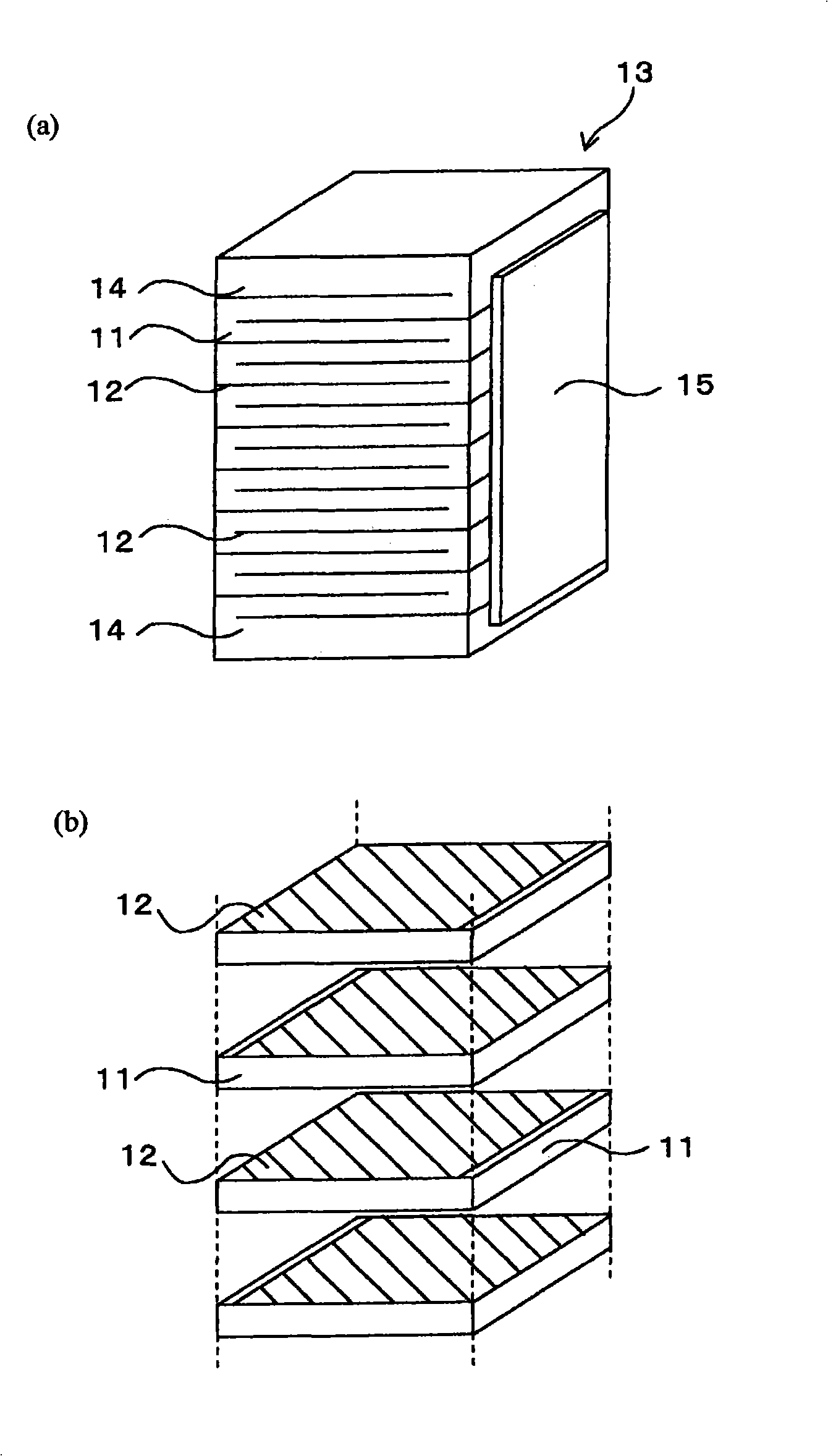

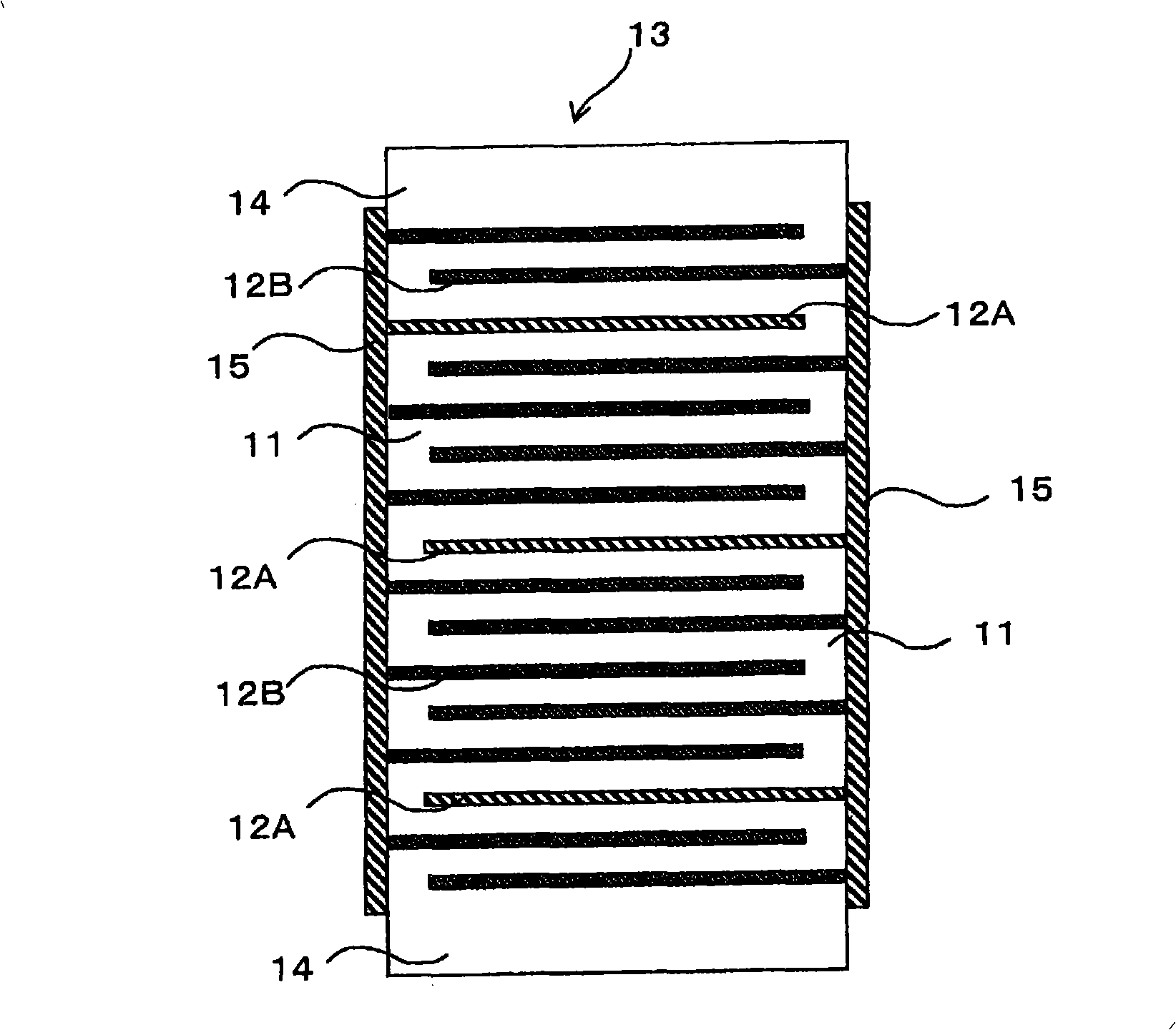

[0042] The multi-layer piezoelectric element according to an embodiment of the present invention will be described in detail with reference to the drawings. figure 1 (a) is a perspective view showing the multi-layer piezoelectric element according to this embodiment, figure 1 (b) is a partial perspective view showing the laminated state of the piezoelectric body layer and the metal layer in the multi-layer piezoelectric element. figure 2 It is a cross-sectional view of the laminated structure of the metal layer in contact with the laminated body layer of the multi-layer piezoelectric element according to the first embodiment.

[0043] Such as figure 1 As shown, this multi-layer piezoelectric element has a laminate 13 in which piezoelectric layers 11 and metal layers 12 are alternately laminated, and a pair of external electrodes 15 are respectively joined to each other. The external electrodes 15 are opposed to each other in the laminate layer 13. The end of the metal layer 12...

no. 2 approach

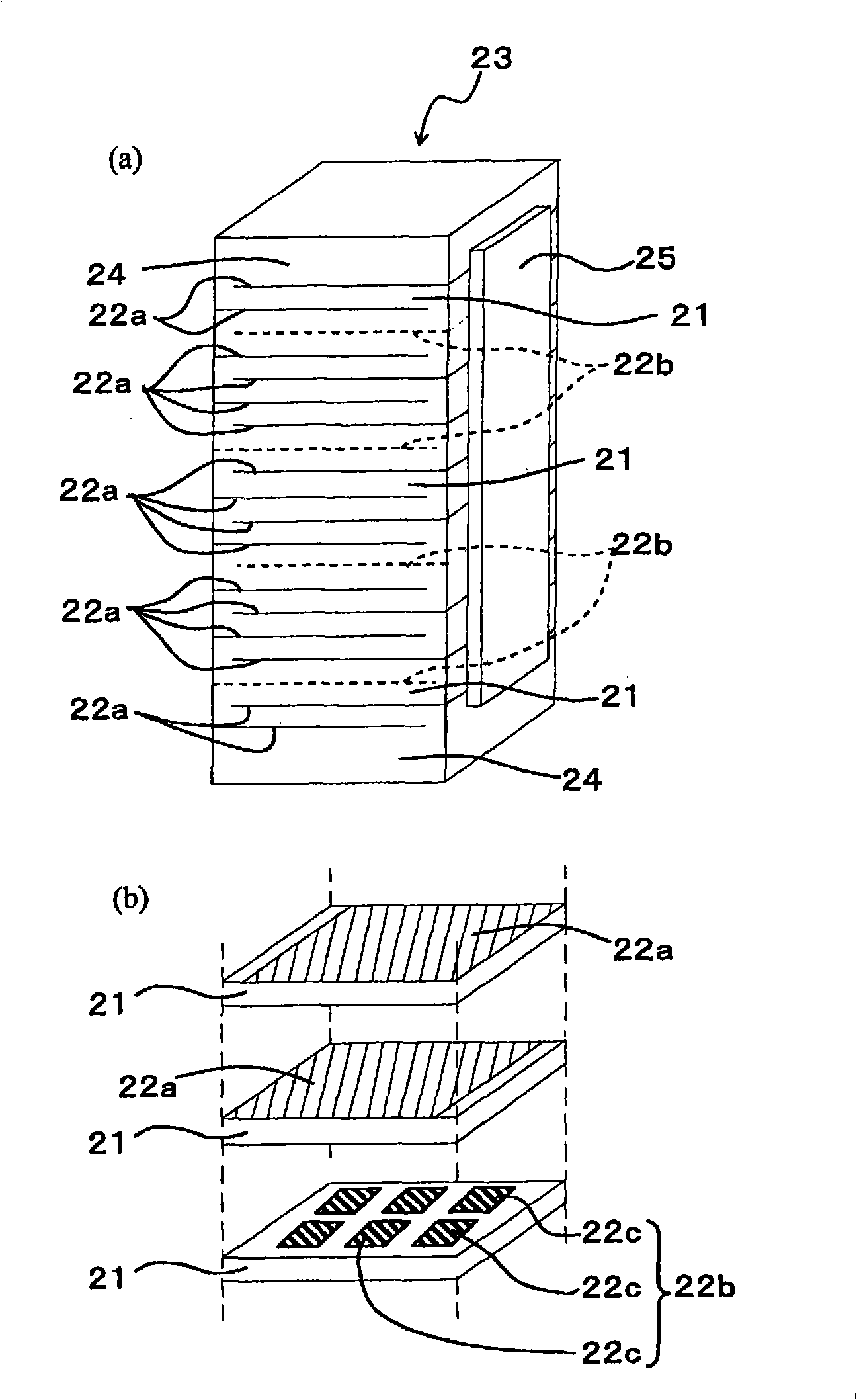

[0090] The multi-layer piezoelectric element according to the second embodiment of the present invention will be described in detail. FIG. 13(a) is a perspective view showing the multi-layer piezoelectric element according to this embodiment, and FIG. 13(b) is a partial perspective view of the laminated state of the piezoelectric layer and the metal layer in FIG. 13(a).

[0091] Such as image 3 As shown in (a) and (b), the multi-layer piezoelectric element of this embodiment has a plurality of piezoelectric body layers 21 and a plurality of metal layers 22a, 22b (hereinafter collectively referred to as "metal layers 22") stacked alternately. The laminated body 23 is provided with a pair of external electrodes 25 (one external electrode is not shown) on opposing side surfaces of the laminated body 23. Each metal layer 22 is not formed on the entire main surface of the piezoelectric body layer 21, that is, constitutes a so-called partial electrode structure. The plurality of metal ...

Embodiment 1

[0123] (Example 1) A piezoelectric actuator composed of the multi-layer piezoelectric element of the present invention was produced as follows.

[0124] First, lead zirconate titanate (PbZrO) with an average particle diameter of 0.4μm is mixed. 3 -PbTiO 3 The calcined powder, binder, and plasticizer of piezoelectric ceramics with) as the main components are made into a slurry, and a ceramic printed circuit board that becomes the piezoelectric body 11 with a thickness of 150 μm is produced by a doctor blade method or the like.

[0125] On one surface of the ceramic printed circuit board, a conductive paste containing a binder added to a silver-palladium alloy (95% by mass silver to 5% by mass palladium) was printed by a screen printing method. At this time, in the part where the other metal layer 12B is formed, a conductive paste with a binder added to a silver-palladium alloy (95% by mass of silver-5% by mass of palladium) is used for printing so that it becomes 5 or 10 μm after f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com