Method for processing nano-function textile

A technology of nanometer function and processing method, which is applied in the direction of textiles, papermaking, fiber treatment, etc., can solve the problems of process stability restricting industrialization, etc., and achieve the effect of excellent nanometer function and adhesion, simple process, and no waste water and waste gas discharge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] 5g of magnesium chloride is coated with liquid paraffin, and then dispersed in 100ml of deionized water containing 0.5g of sodium dodecylbenzenesulfonate under high-speed stirring to form a stable emulsion system, and 5g of cotton fabric is passed through the above emulsion system. Padding treatment, the control liquid rate is 85%. After the padding treatment, the fabric stays in the ammonia gasification chamber for 50 minutes, and then undergoes 3 minutes of pre-baking at 80°C and 2 minutes of baking at 130°C to obtain flame-retardant fabrics. of textiles.

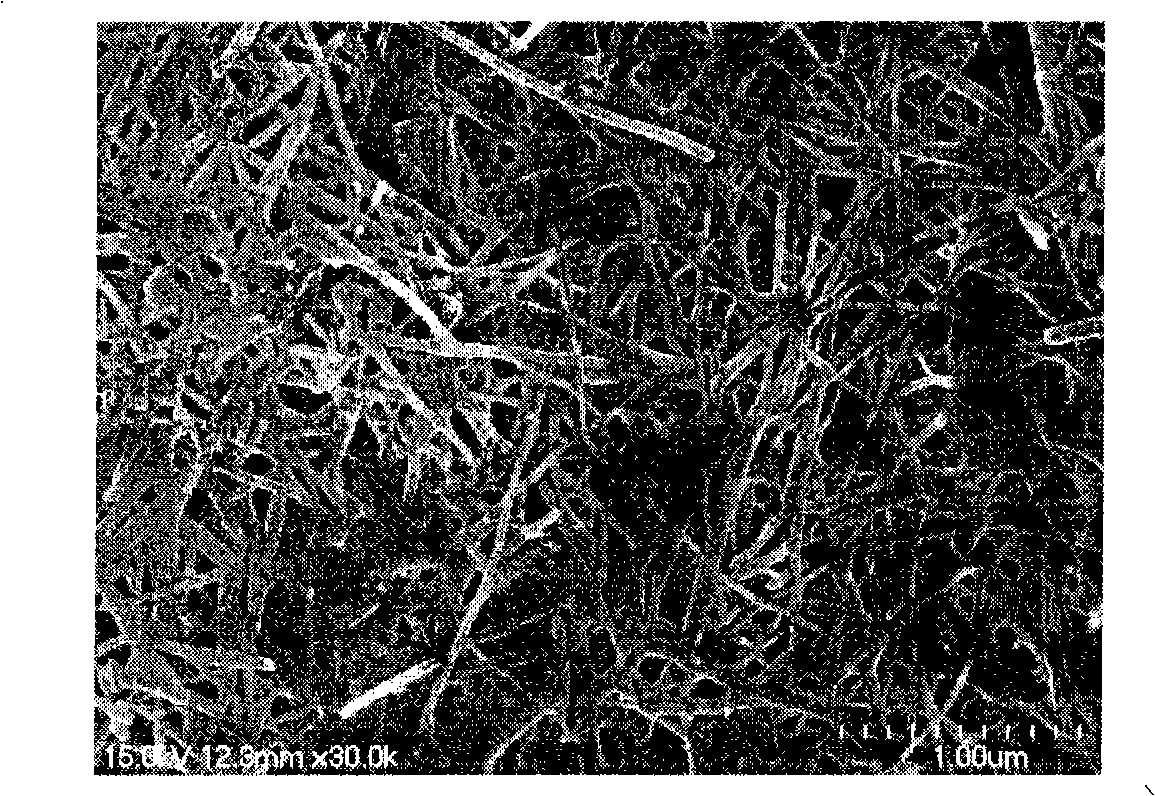

[0022] See attached figure 1 , which is the scanning electron micrograph of the nano-functional textile produced by the processing method described in this example; its surface presents fibrous nanomaterials with a diameter of nanometers, and the distribution is uniform without obvious agglomeration.

Embodiment 2

[0024] Coat 5g of zinc nitrate with glycerin, and then disperse it in 100ml of deionized water containing 0.1g of polymeric dispersant CH-12B under high-speed stirring to form a stable emulsion system, and then put 5g of silk fabric in the above emulsion system After padding treatment, the liquid rate is controlled to 75%. The fabric after padding treatment stays in the ethylamine atomization chamber for 20 minutes, and then undergoes 3 minutes of pre-baking at 80°C and 2 minutes of baking at 100°C to obtain antibacterial fabrics. , Anti-UV textiles.

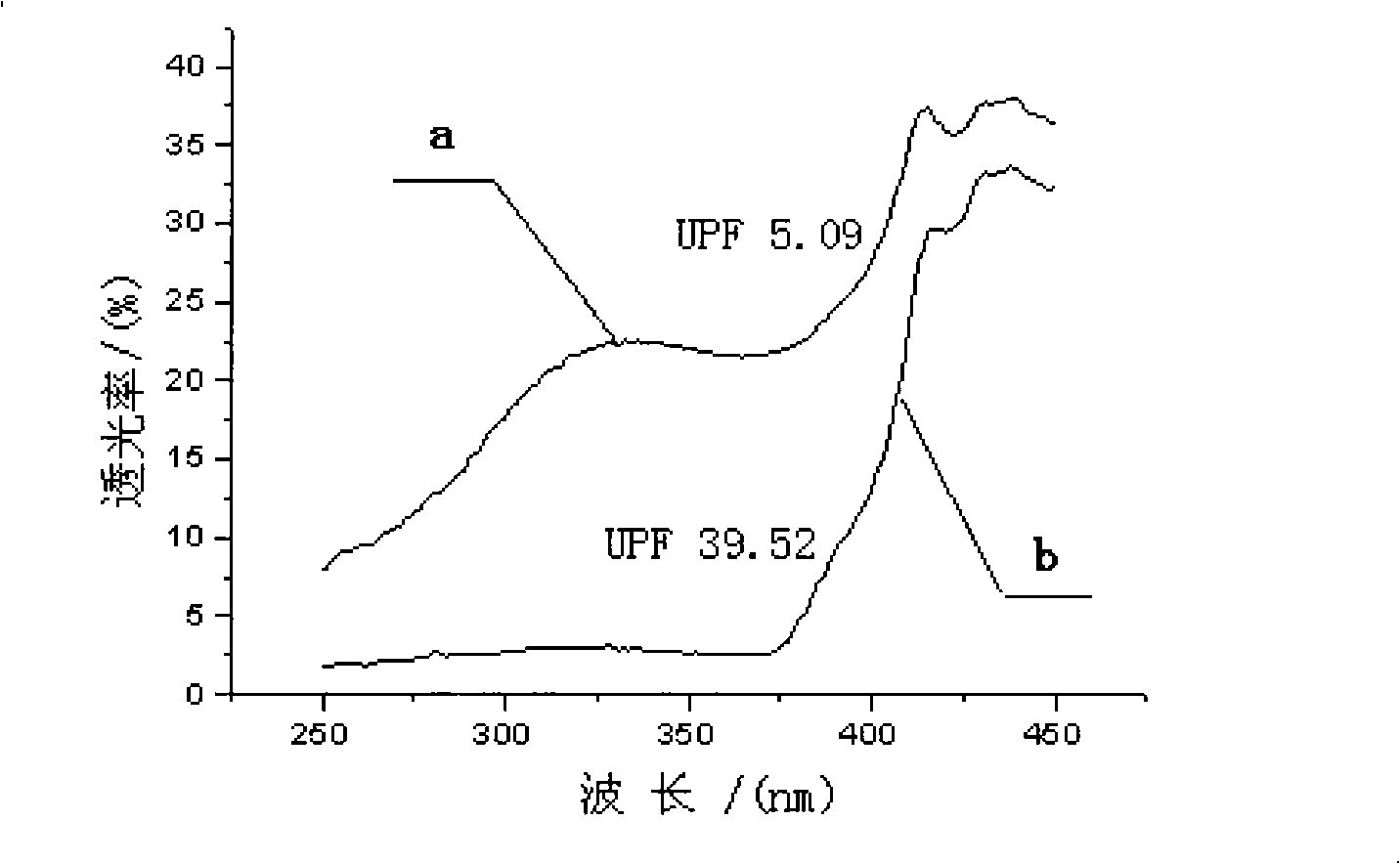

[0025] See attached figure 2 , which is a comparison chart of the ultraviolet absorption curves of nano-functional textiles prepared according to the technical scheme of this embodiment and fabrics without nano-processing; wherein, curve a is the fabric without nano-processing, and curve b is the fabric after nano-processing; According to the analysis results of the ultraviolet absorption spectrum, the nano-processed fabric ha...

Embodiment 3

[0028] Coat 2.0g of silver nitrate with ethyl acetate, and then disperse it in 100ml of deionized water containing 0.2g of polyvinylpyrrolidone under high-speed stirring to form a stable emulsion system, and then soak 5g of polyester fabric in the above emulsion system. Padding treatment, the control liquid rate is 75%. After the padding treatment, the fabric stays in the urea atomization chamber for 10 minutes, and then undergoes 3 minutes of pre-baking at 80°C and 2 minutes of baking treatment at 120°C to obtain antistatic and antibacterial fabrics. Functional textiles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com