Weaving technique for multicolor layer-collection high-grade flax knitting fabric

A technology for knitted fabrics and knitted fabrics, applied in knitting, weft knitting, textiles and papermaking, etc., can solve the problems of unsalable domestic products, low number of linen textile products, and low grades, and achieve the effect of avoiding end breakage and delicate appearance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

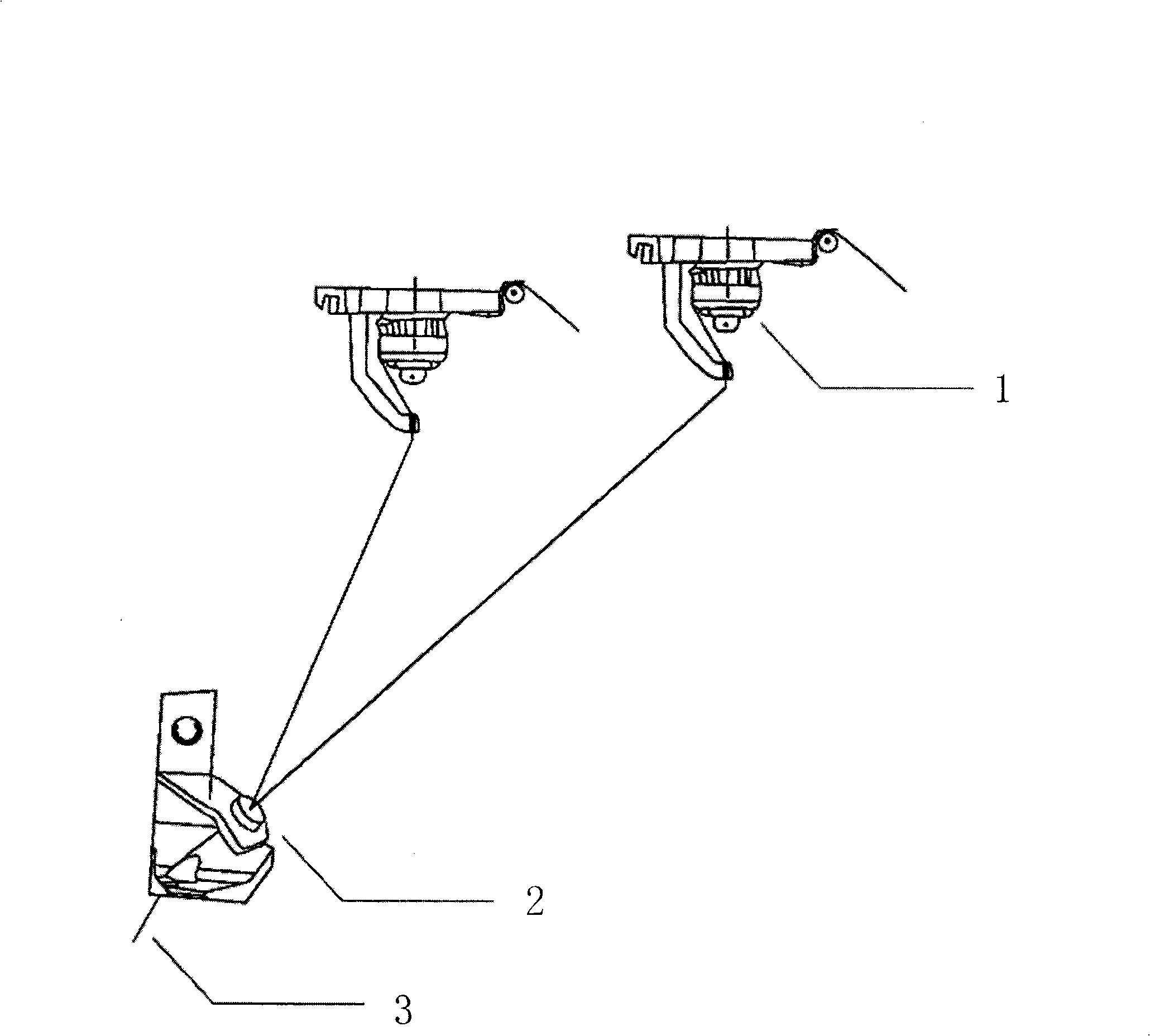

Image

Examples

Embodiment Construction

[0020] The invention relates to a weaving process of multi-color multi-layer high-grade linen knitted fabric,

[0021] 1. Material preparation: the yarn of the required color is ready for use;

[0022] 2. Clear the dyed yarn: the yarn first passes through the winder to eliminate the bamboo and hemp particles in the flax yarn, and wax: the yarn passes through the wax block with a central hole, and the yarn passes through the winding Tube machine, winding tower yarn with quality suitable for knitting circular knitting machine;

[0023] 3. The entangled qualified tower yarns are placed on the creel around the circular knitting machine according to the preset color order of the computer jacquard circular knitting machine, and then the divided yarns are sent to the computer jacquard circular knitting machine every two yarns of the same color A yarn feeder arranged in sequence is called double yarn feeding;

[0024] 4. Adopt the computer jacquard control program of the electric ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com