Method for preparing composite emulsion of epoxy resin-polyurethane

A technology of epoxy resin and composite emulsion, which is applied in the field of coating science and functional polymers. It can solve the problems affecting the performance of the composite system, the difficulty of phase inversion emulsification, and the high viscosity of the prepolymer, so as to improve the mechanical strength and solvent resistance. Improve the mechanical properties and increase the effect of cross-linking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

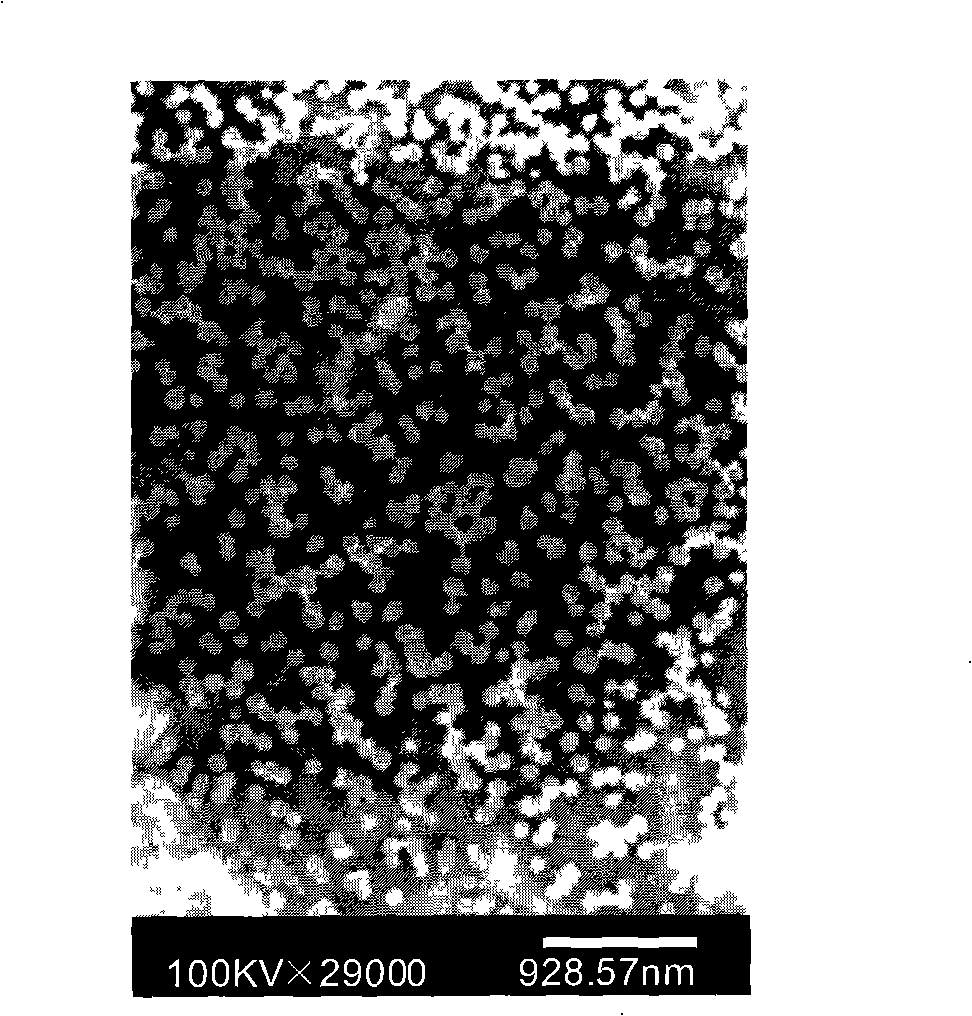

Image

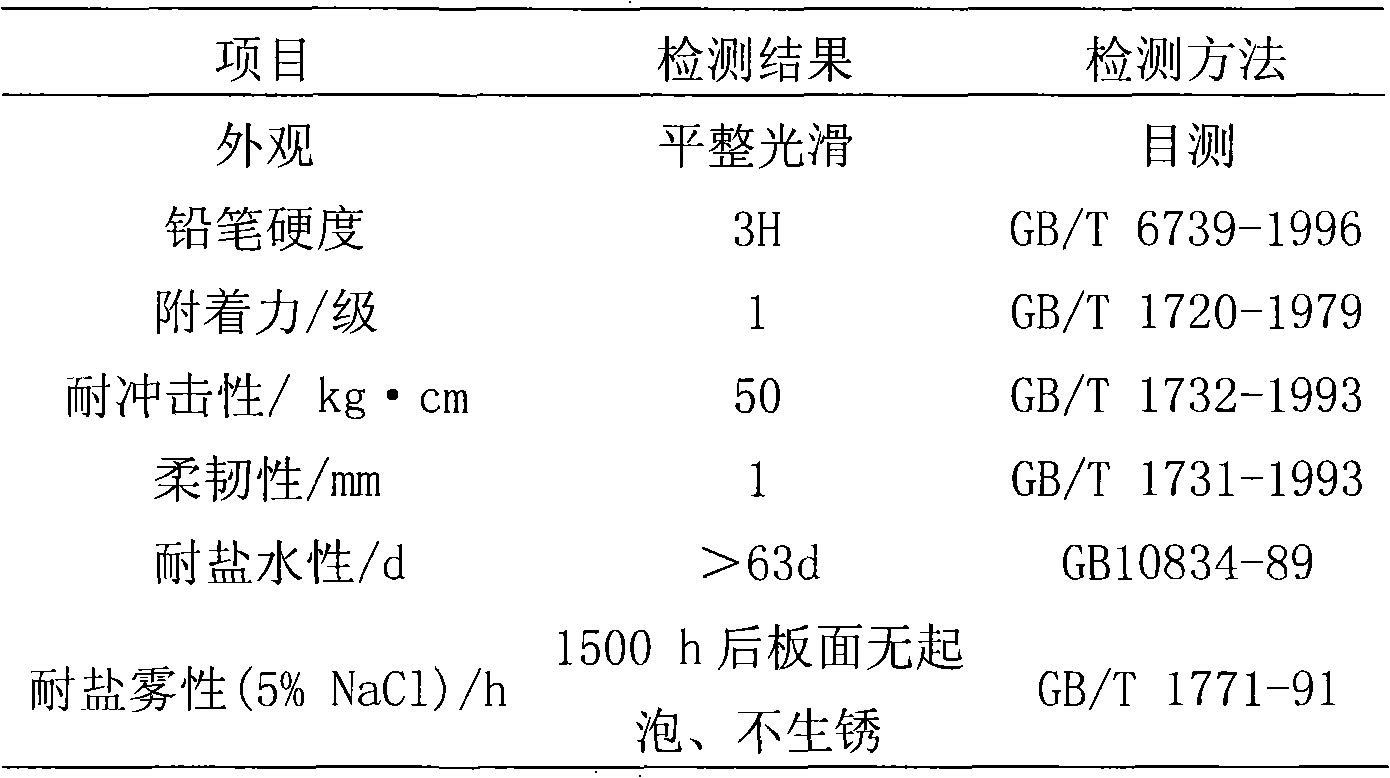

Examples

Embodiment 1

[0030] A preparation method of epoxy resin-polyurethane composite emulsion, comprising the following steps:

[0031]Under dry nitrogen protection, 3g polyester diol (PBA, Mn=2000, hydroxyl value 53~56mgKOH / g, industrial grade, Yantai Huada Chemical Co., Ltd.), 6g polycarbonate diol ( PCD, Mn=2000, hydroxyl value 56 ± 3mgKOH / g, C.P., Shanghai Hersbit Chemical Co., Ltd.) and 5g isophorone diisocyanate (IPDI, C.P., Hurls Company, Germany) were added to an electric stirrer equipped with reflux In a 250ml four-neck flask with a condenser tube and a thermometer, heat up to 90°C and react at a constant temperature for 60 minutes; add 3g of dimethylolpropionic acid, continue the reaction at 90°C for 60min, add 0.3g of trimethylolpropane, and continue at 90°C After reacting for 60min, the mixture of epoxy resin and diethanolamine (ratio of the amount of substance is 1: 1) was added in another four-necked flask at 60 ℃ for 120min (the addition of epoxy resin and diethanolamine is 0.5g ...

Embodiment 2

[0047] A preparation method of epoxy resin-polyurethane composite emulsion, comprising the following steps:

[0048] 1) Under the protection of nitrogen, mix the polyisocyanate and the oligomer diol in a mass ratio of 5:7, heat up to 70°C, and react at a constant temperature for 60 minutes to obtain a linear urethane prepolymer; the polyisocyanate is toluene diisocyanate , the oligomer diol is polyester polyol;

[0049] 2) Add a small molecule chain extender to the linear urethane prepolymer in step 1), continue to react at 70°C for 30 minutes, then add a macromolecular hydrophilic chain extender, and continue to react at 70°C for 45 minutes to obtain urethane prepolymer polymer; wherein, the mass ratio of polyisocyanate to small molecule chain extender is 5:3.0, the mass ratio of polyisocyanate to macromolecular hydrophilic chain extender is 5:0.6; the small molecule chain extender is dimethylolpropane Acid, macromolecular hydrophilic chain extender is epoxy resin-amine addu...

Embodiment 3

[0053] A preparation method of epoxy resin-polyurethane composite emulsion, comprising the following steps:

[0054] 1) Under the protection of nitrogen, mix polyisocyanate and oligomer diol in a mass ratio of 5:11, heat up to 90°C, and react at a constant temperature for 90 minutes to obtain a linear urethane prepolymer; the polyisocyanate is isophor Ketone diisocyanate; oligomer diols are polycarbonate polyols and polyether polyols, polycarbonate polyols and polyether polyols each account for 1 / 2 of the mass of oligomer diols; all polycarbonate polyols Alcohol, polyether polyol can realize the present invention;

[0055] 2) Add a small molecular chain extender to the linear urethane prepolymer in step 1), continue to react at 90°C for 60 minutes, then add a macromolecular hydrophilic chain extender, and continue to react at 90°C for 60 minutes to obtain urethane prepolymer polymer; wherein, the mass ratio of polyisocyanate to small molecule chain extender is 5:3.7, the mass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com