Ignition method and apparatus of product line for sintering porcelain granule

An ignition device and production line technology, applied in applications, household appliances, and other household appliances, etc., can solve the problems that the ignition device has not been discussed in detail, and achieve the effects of simple structure, reduced heat energy waste, and sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

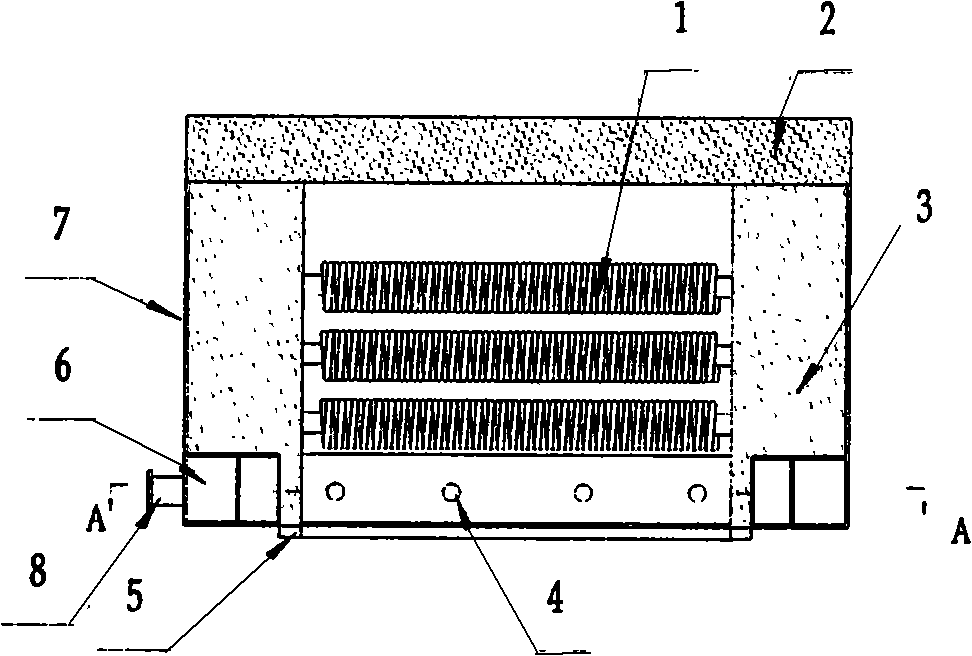

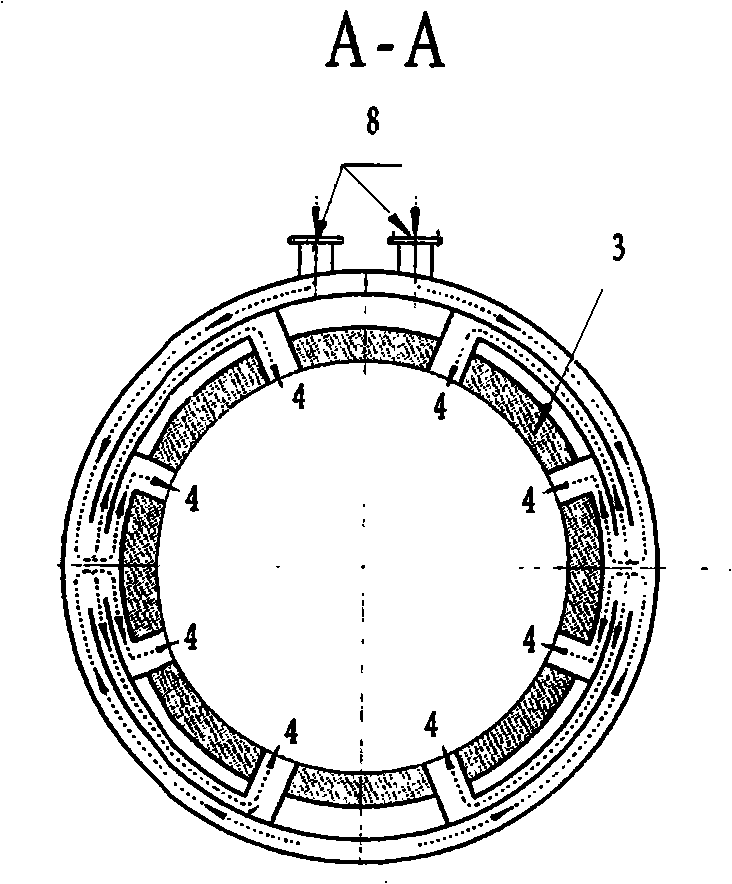

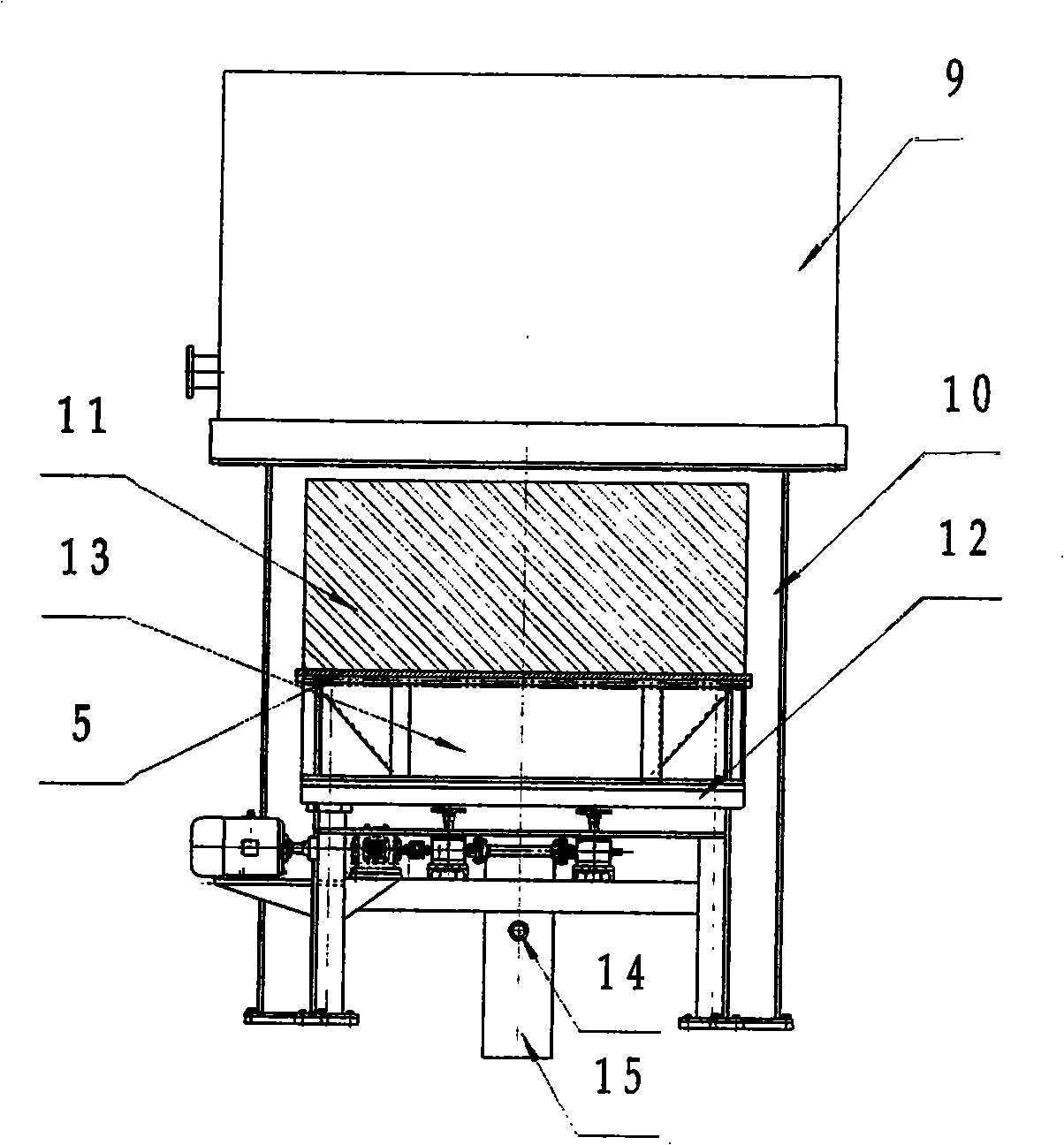

[0049] The specific implementation manners of the present invention will be described below in conjunction with the accompanying drawings.

[0050] The special ignition device for the sintered ceramsite production line of the present invention has the following structural features:

[0051] Electricity is used as the ignition energy instead of other fuels such as fuel oil, natural gas or coal. If natural gas, fuel oil or coal powder is used to ignite, the flame has a certain pressure and destructiveness, so the ignition method of the present invention will not damage the ignition surface of the sintered raw material.

[0052] The internal structural space of the ignition device can be a cylinder, a square cylinder or a polyhedron. The top is closed or adopts a heat-insulating breathable layer (or hole) to release the water vapor generated in the preheating step of the ignition process; the bottom is open, and a combustion-supporting gas channel is installed. Electric heating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com