Intelligent type volume type constant-current flow gauge and measuring control method

A volumetric and intelligent technology, applied in the flow control of electric devices, etc., can solve the problems of affecting the accuracy of flow control, impact, and increased maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

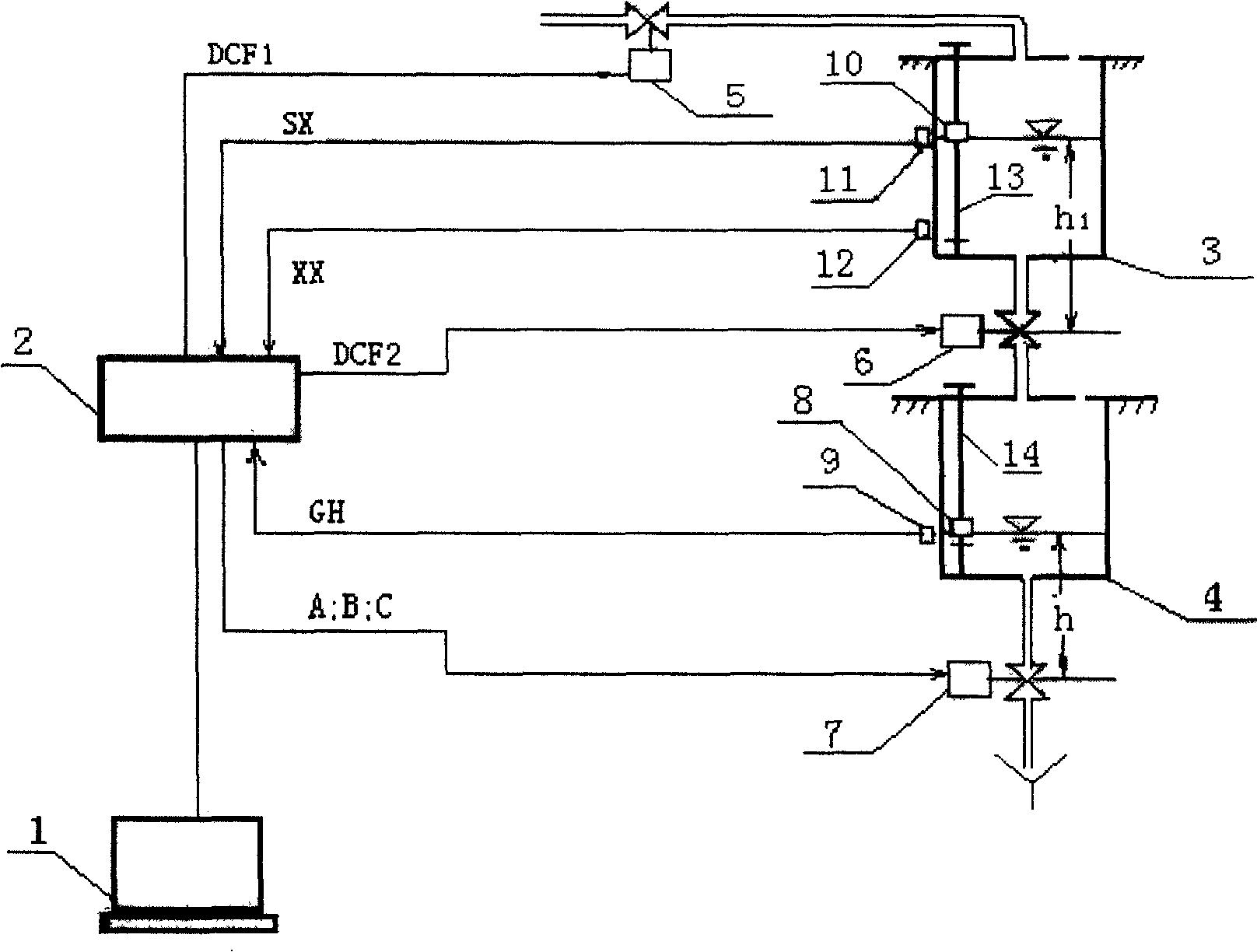

[0008] exist figure 1 Among them, the constant flow barrel (4) is open, and the valve outlet of the stepping electric actuator (7) is free flow. Assuming that the stepping electric actuator (7) valve outlet to the liquid level height of the constant flow barrel (4) is h, the stepping electric actuator (7) valve flow cross section is A, and the flow through the valve is according to the tori (E. Torricelli, 1644) formulas are:

[0009] Q = μA 2 gh - - - ( a )

[0010] Among them, μ is called the flow correction coefficient.

[0011] It is assumed that the increase or decrease of the valve stem displacement L of the stepping electric actuator (7) is linearly related to the increase or decrease of the valve flow section A

[0012] A=kL (b)

[0013] kScale factor.

[0014] (a)(b) incorporates:

[0015] Q ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com