Self-supporting through-hole alumina film preparation method

A kind of aluminum oxide film, self-supporting technology, applied in the direction of anodic oxidation, etc., can solve the problems of injury, easy pollution of the environment, personal life, long peeling time, etc., and achieve the effect of simple operation, low energy consumption and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] In this embodiment, a self-supporting through-hole aluminum oxide film is specifically prepared according to the following steps and conditions.

[0019] (1) Pretreatment: First, the metal aluminum sheet with a thickness of 0.1 mm and a purity of 99.5% is washed in acetone and ethanol in sequence to remove surface oil, dried in the atmosphere, and then annealed at 500 ° C for 2 hours in an oxygen atmosphere ;

[0020] (2) Electrochemical polishing: the pretreated metal aluminum sheet was electrochemically polished for 3 minutes in a mixed solution of perchloric acid and ethanol with a volume ratio of 1:9, and the voltage was 15V;

[0021] (3) Anodic oxidation: the electrolytic solution is selected as 0.3M oxalic acid, and the voltage is 40V, and the polished aluminum sheet is anodized for 6 hours;

[0022] (4) Thinning the barrier layer: use the current recovery method to reduce the voltage by 1V each time, until the power is turned off after 1V;

[0023] (5) Electrol...

Embodiment 2

[0025] The process and steps of Example 1 were repeated, and the voltage was -4.5V during the electrolytic film stripping and through-hole process, and the electrolysis was performed for 10 minutes to produce a product.

Embodiment 3

[0027] The process and steps of Example 1 were repeated, and the voltage was -5V during the electrolytic stripping and through-hole process, and the electrolysis was performed for 3 minutes to produce a product.

[0028] The voltages used in the electrochemical process in the above examples are all provided by a DH1716 DC stabilized voltage and stabilized current power supply.

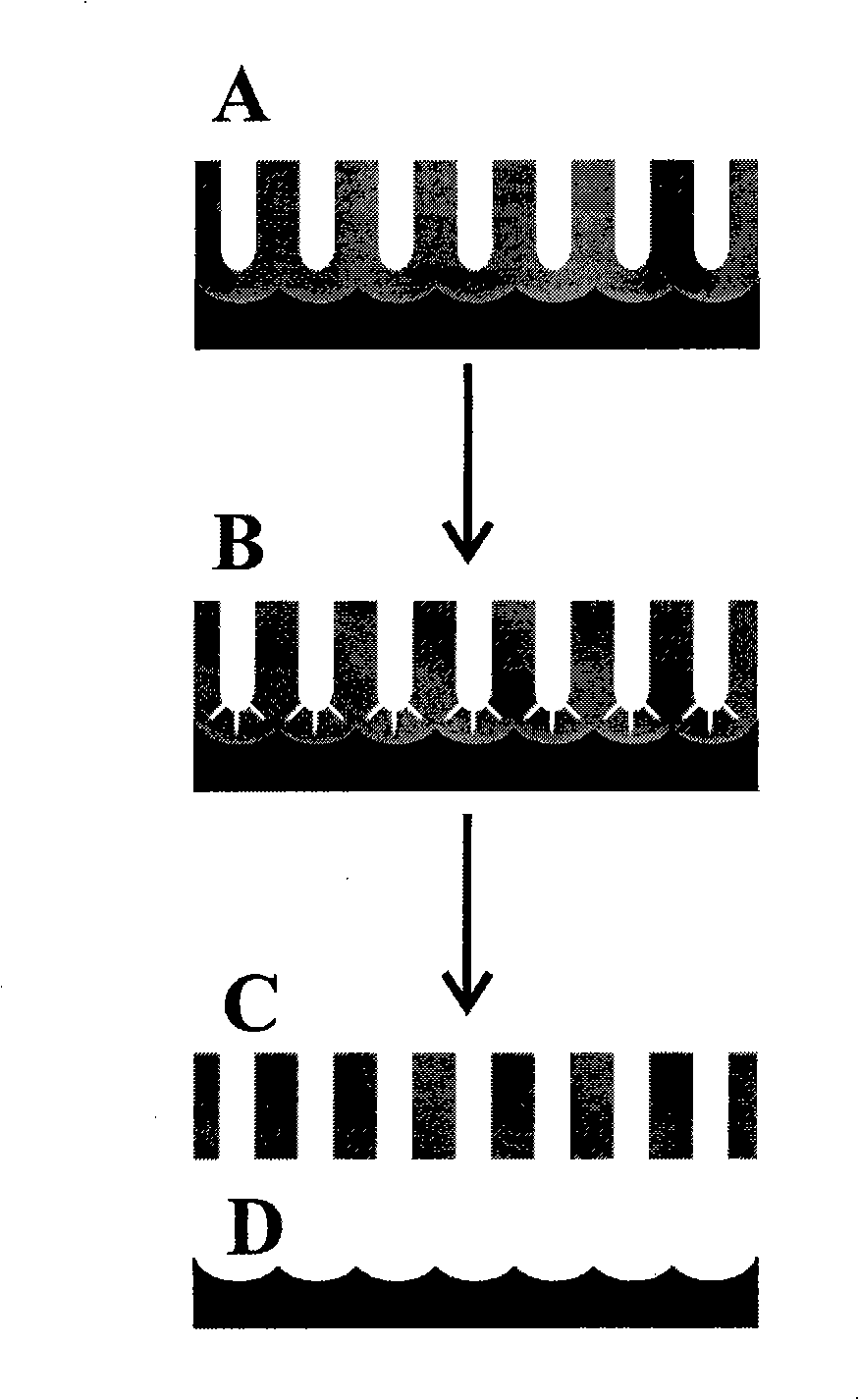

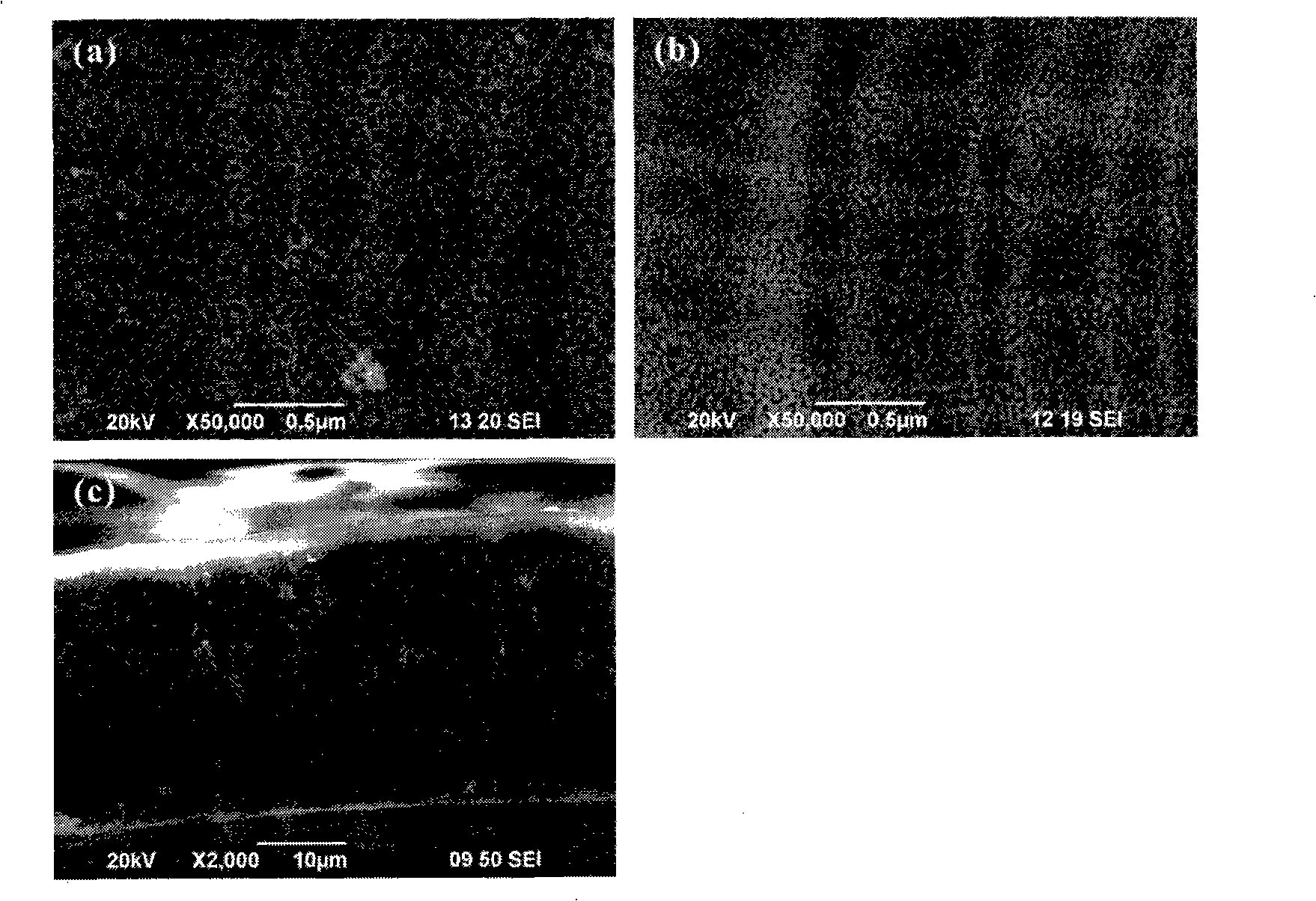

[0029] To above-mentioned embodiment and product thereof in conjunction with appendix figure 1 For the analysis, the electrochemically polished metal aluminum sheet is first oxidized by anodic oxidation method to form an aluminum oxide film (A) on the surface, and the barrier layer separates the porous aluminum oxide layer from the metal aluminum substrate, and its thickness satisfies the constant pressure corrosion condition A linear relationship of 1.4nm / V; secondly, the barrier layer (B) was thinned by the current recovery method. Since the thickness of the barrier layer is proportional to the anod...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com