Method for preparing 2,3,4-trimethoxybenzoic acid

A technology of trimethoxybenzoic acid and raw materials, applied in the field of pharmaceutical intermediates 2, can solve problems such as large pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

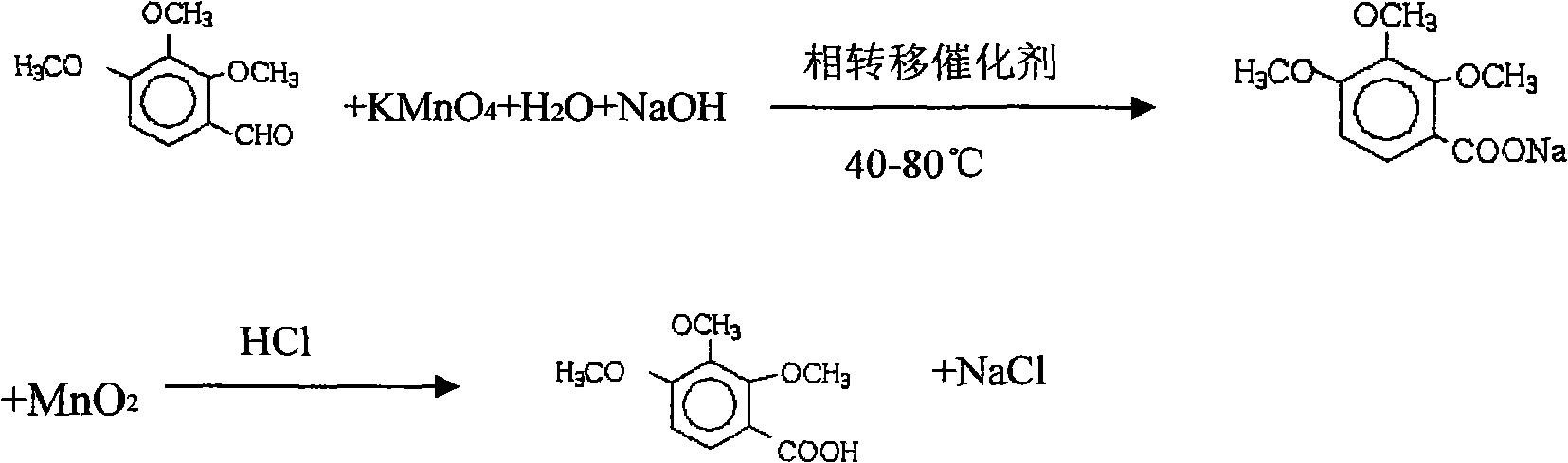

Method used

Image

Examples

Embodiment 1

[0018] ① Dissolve 16.5g of sodium hydroxide in 700g of water, stir to dissolve;

[0019] ②Add 65g of 2,3,4-trimethoxybenzaldehyde to the above alkaline solution, raise the temperature to 50°C, and stir to form an oil-water two-phase solution system;

[0020] ③Add 2g of tetrabutylammonium bromide to the above solution;

[0021] ④ Under stirring, add 39 g of potassium permanganate to it, and control the temperature to 45-45°C. After reacting for 2 hours, the temperature was raised to 55-60°C and reacted for 1 hour.

[0022] ⑤ Vacuum filtration, and wash the filter cake with 50×3 ml of water, and combine the filtrate and washing liquid.

[0023] ⑥ Adjust the pH to 7-8 with 3-5g 35% hydrochloric acid. Add 2g of activated carbon and 2g of sodium bisulfite, heat up to 80-85°C, decolorize for 15 minutes, and vacuum filter;

[0024] ⑦Take the filtrate, add 70g 35% hydrochloric acid, adjust the pH to 1-2, at this time a large amount of white precipitate is formed, stir and cool to 5-10°C, ...

Embodiment 2

[0027] ① Dissolve 38g potassium carbonate in 700g water and stir to dissolve;

[0028] ②Add 65g of 2,3,4-trimethoxybenzaldehyde to the above alkaline solution, raise the temperature to 50°C, and stir to form an oil-water two-phase solution system;

[0029] ③Add 2g of tetrabutylammonium chloride to the above solution;

[0030] ④ Under stirring, add 39 g of potassium permanganate to it, and control the temperature to 45-45°C. After reacting for 2 hours, the temperature is raised to 55-60°C and reacted for 1 hour;

[0031] ⑤ Vacuum filtration, and wash the filter cake with 50×3 ml of water, and combine the filtrate and washing liquid;

[0032] ⑥ Adjust the pH to 7-8 with 3-5g 35% hydrochloric acid. Add 2g of activated carbon, 2g of sodium bisulfite, heat to 80-85°C, decolorize for 15 minutes, vacuum filter, and wash the precipitate with 50×3 ml of water;

[0033] ⑦Take the filtrate and add 70g 35% hydrochloric acid to adjust the pH to 1-2. At this time, a large amount of white precip...

Embodiment 3

[0036] ① Dissolve 29g of sodium carbonate in 700g of water and stir to dissolve;

[0037] ②Add 65g of 2,3,4-trimethoxybenzaldehyde to the above alkaline solution, raise the temperature to 50°C, and stir to form an oil-water two-phase solution system;

[0038] ③Add 2g of benzyltriethylammonium chloride to the above solution;

[0039] ④ Under stirring, add 39 g of potassium permanganate to it, and control the temperature to 45-45°C. After reacting for 2 hours, the temperature is raised to 55-60°C and reacted for 1 hour;

[0040] ⑤ Vacuum filtration, and wash the filter cake with 50×3 ml of water, and combine the filtrate and washing liquid;

[0041] ⑥ Adjust the pH to 7-8 with 3-5g 35% hydrochloric acid. Add 2g of activated carbon and 2g of sodium bisulfite, heat up to 80-85°C, decolorize for 15 minutes, and vacuum filter;

[0042] ⑦Take the filtrate and add 70g 35% hydrochloric acid to adjust the pH to 1-2. At this time, a large amount of white precipitate is formed, stir and cool ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com