Liquid concrete activating agent

A technology of concrete and activator, applied in the field of building materials, can solve the problems of increasing the turnover demand of formwork, difficult to popularize and apply, long setting time, etc., and achieve the effects of shortening setting time, saving cost and improving early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Naphthalene superplasticizer: 15%

[0021] Aluminum sulfate: 15%

[0022] Triethanolamine: 0.05%

[0023] Air content regulator: 0.2%

[0024] Hydroxy compound 0.012%

[0025] Water: 69.74%

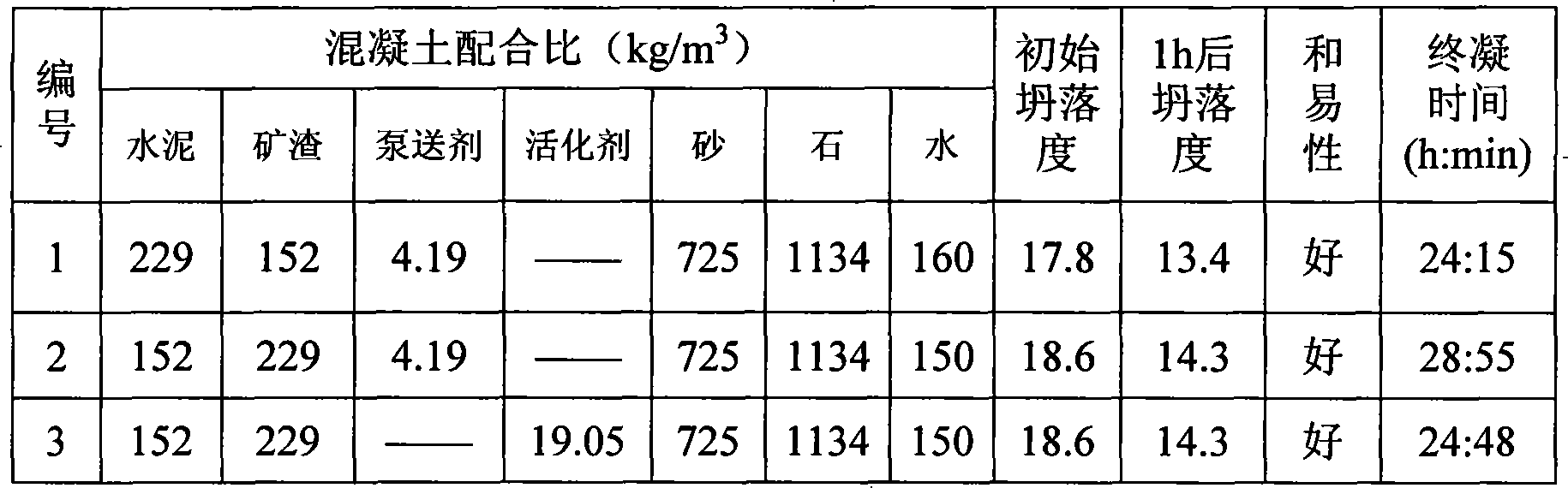

[0026] Table 1-Table 2 shows the mixing ratio and properties of large-volume ground-slag concrete prepared by mixing 5% of the amount of cementitious material with the liquid large-volume ground-fine slag concrete activator prepared in this example.

[0027] Table 1 Concrete mix ratio and mixture properties

[0028]

[0029] Table 2 Concrete compressive strength (MPa)

[0030] Numbering

[0031] It can be seen from Tables 1 to 2 that after adding a large amount of liquid ground slag activator, the ground slag in the concrete cementitious material system increases from 40% to 60%, and the setting time of concrete, the early strength of concrete and the later Intensity was basically unchanged. The setting time of 60% ground slag concrete without liquid activator i...

Embodiment 2

[0032] Embodiment 2 is substantially the same as Embodiment 1, but the formula is:

[0033] Naphthalene superplasticizer: 15%

[0034] Aluminum sulfate: 10%

[0035] Air content regulator: 0.2%

[0036] Water: 74.8%

Embodiment 3

[0037] Embodiment 3 is substantially the same as Embodiment 1, but the formula is:

[0038] Sulfamate superplasticizer: 45%

[0039] Aluminum sulfate: 13%

[0040] Triethanolamine: 0.05%

[0041] Air content regulator: 0.2%

[0042] Hydroxy compounds: 0.01%

[0043] Water: 41.74%

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com