Impacting pickaxe

A technology of impact picks and pick bodies, applied in the field of impact picks, which can solve the problems of high manufacturing and maintenance costs of impact picks, low energy utilization rate of impact picks, and high parts precision requirements, and achieve low manufacturing and maintenance costs, light weight, and reduced labor. The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

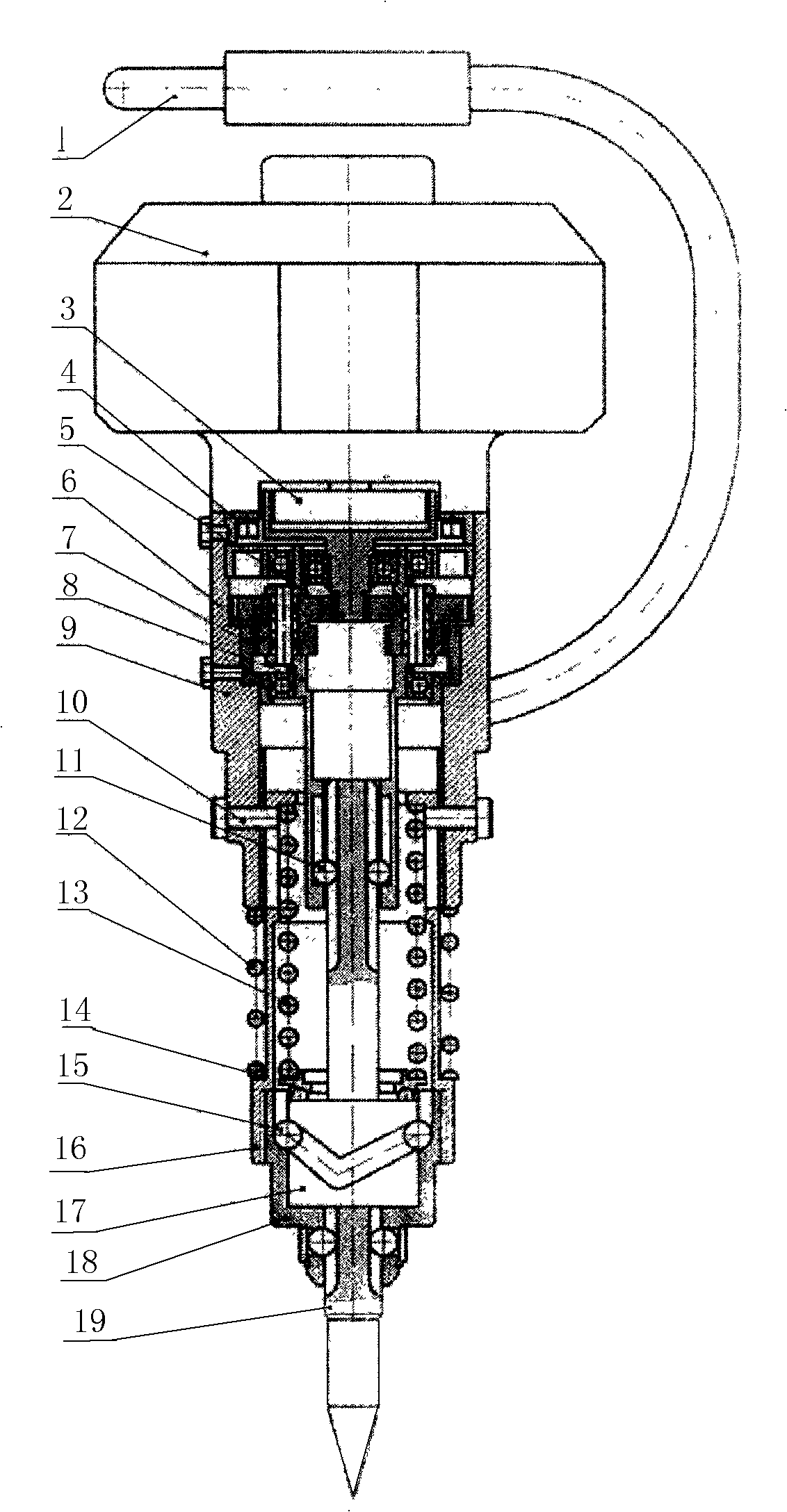

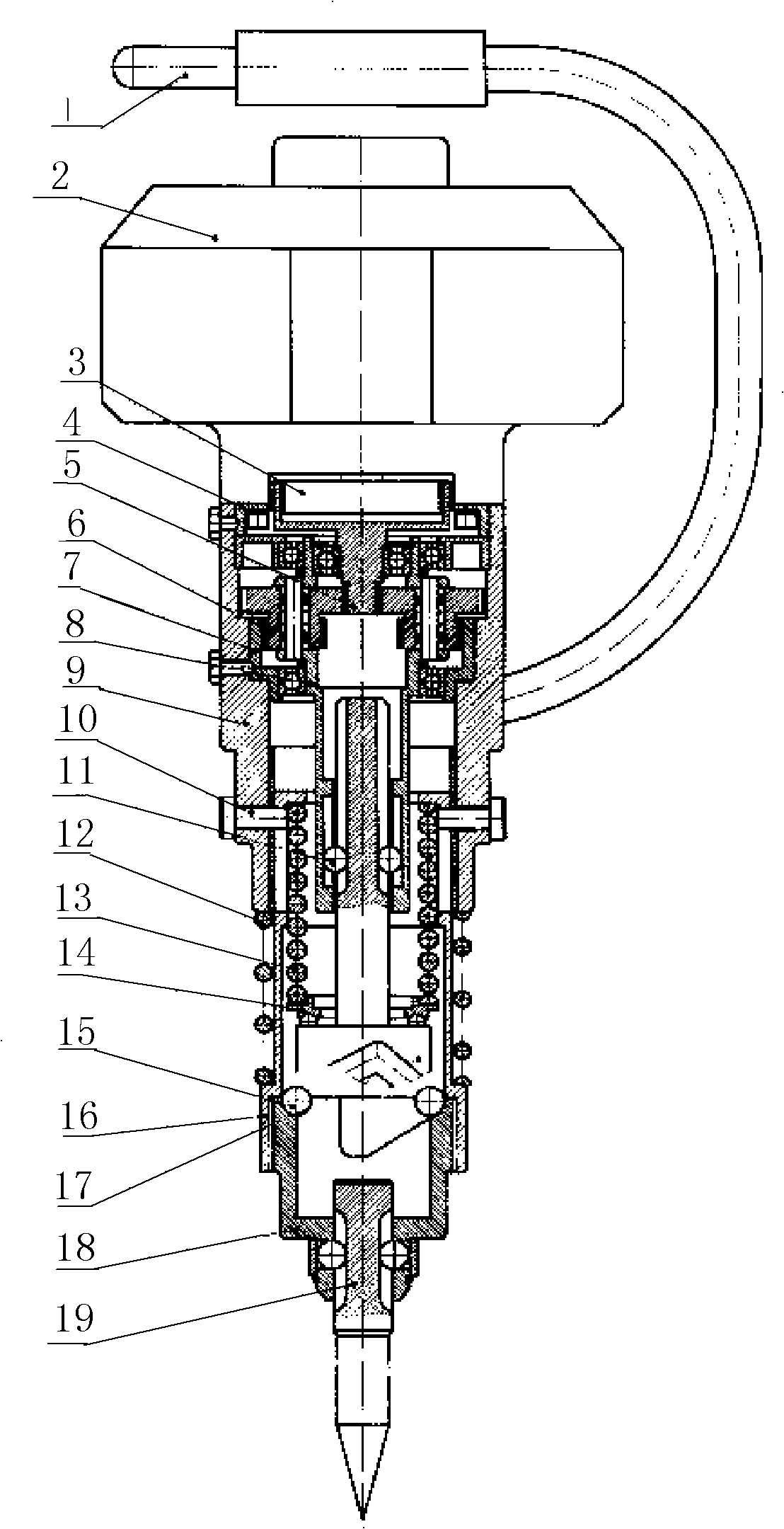

[0012] Below in conjunction with accompanying drawing example, the present invention is described in further detail:

[0013] figure 1 with figure 2 Shown is an impact pick equipped with an internal combustion engine 2, the top of its pick body 9 is equipped with an internal combustion engine 2 through a connecting plate 4, and the middle part is equipped with an armrest frame 1, and the power of the internal combustion engine 2 is transmitted to the center wheel 5 through a centrifugal clutch 3 , the inner gear 7 of the planetary gear reduction mechanism is fixed on the pick body 9, and the center wheel 5 outputs power from the output shaft of the planet carrier 8 through the meshing with the planetary gear 6 and the inner gear 7; the lower part of the pick body 9 passes through the pin 10 A pick barrel 16 is set with the slot hole, and a damping spring 12 is installed between the pick body 9 and the pick barrel 16. A pick hammer 17 is housed in the pick barrel 16, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com