Graphite longitudinal fin flue gas heat exchange tube and its manufacture method

A technology of graphite fins and heat exchange tubes, applied in the field of heat exchange equipment, can solve problems such as poor corrosion resistance, and achieve the effects of small equipment volume, low smoke resistance, and high heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

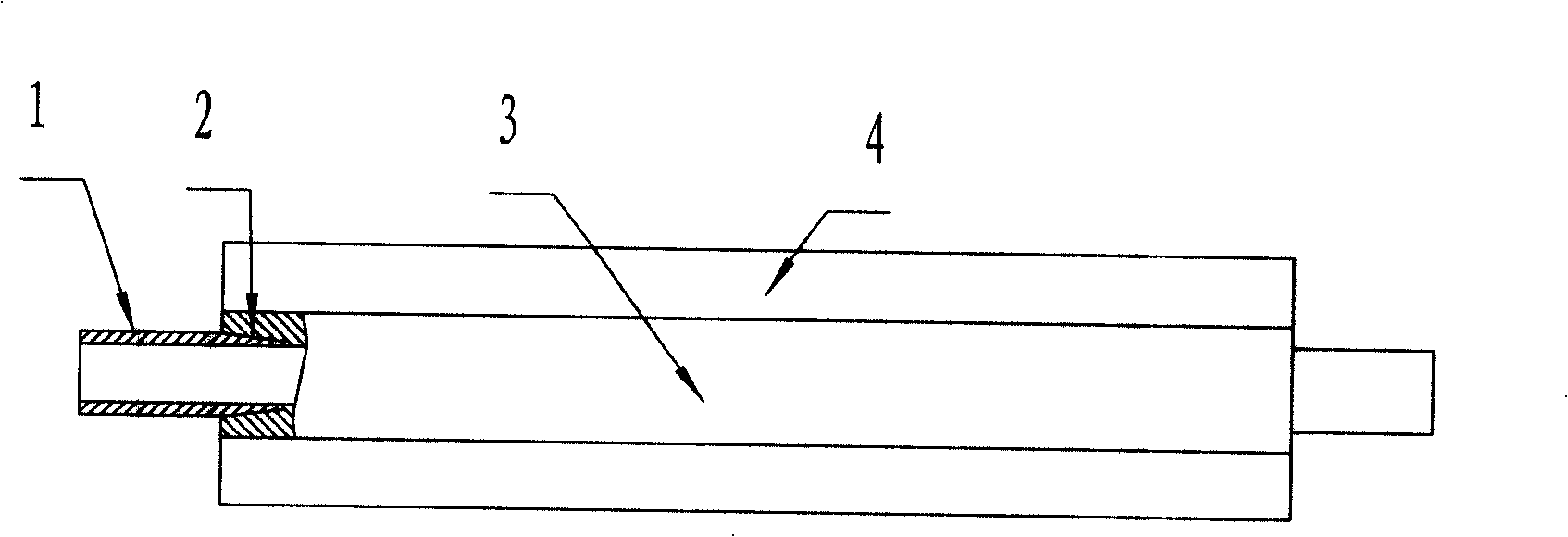

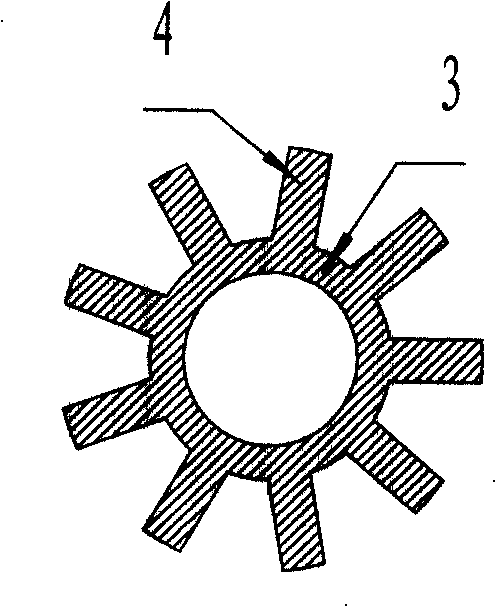

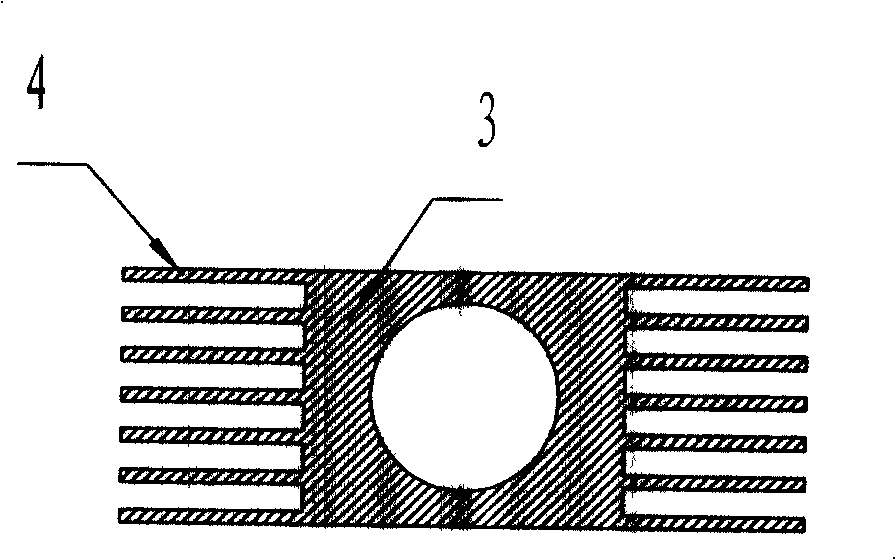

[0020] Embodiment 1, a flue gas heat exchange tube with graphite longitudinal fins, the heat exchange tube includes a tube body and a joint, and its structure is: the tube body is composed of a graphite inner tube 3 and graphite fins distributed longitudinally on the outer surface It is composed of sheet 4, and the two ends of the graphite inner tube are equipped with metal joints 1. The metal joint and the inner pipe are connected by threads, and there is an adhesive layer between the inner thread of the inner pipe and the outer thread of the metal joint.

Embodiment 2

[0021] Embodiment 2, a graphite longitudinal fin flue gas heat exchange tube, the heat exchange tube includes a tube body and a joint, and its structure is: the tube body is composed of a graphite inner tube 3 with a circular cross section and an outer surface Composed of graphite fins 4 distributed longitudinally, the inner tube of the pipe body and the fins distributed longitudinally along the outer surface are extruded with a mold in a special extruder heated internally and externally, and the specific steps are:

[0022] a. Modulate graphite raw material,

[0023] b. Put the raw materials into the special extruder and extrude them into shape,

[0024] c. Drying and curing.

[0025] The special equipment used in the manufacturing method of the graphite longitudinal finned flue gas heat exchange tube includes an outer heating layer 7, an insulating layer 6, a mold 11, and an inner mold 9, wherein an inner heating layer 10 is housed in the tube of the tubular inner mold. Af...

Embodiment 3

[0026] Embodiment 3, a graphite longitudinal fin flue gas heat exchange tube, the heat exchange tube includes a tube body and a joint, and its structure is: the tube body is composed of a graphite inner tube 3 with a circular cross section and an outer surface It consists of graphite fins 4 distributed longitudinally, and metal joints 1 are installed at both ends of the graphite inner tube. The metal joint and the inner pipe are connected by threads, and there is an adhesive layer between the inner thread of the inner pipe and the outer thread of the metal joint, and the inner surface of the graphite inner pipe has longitudinal ribs 5 . Such as figure 1 and Figure 4 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com