High-speed chemical fibre spinning thread-guiding rubber ring and manufacturing method thereof

A technology of high-speed spinning and apron, applied in textiles and papermaking, etc., can solve the problems of inability to guarantee product quality, affecting the service life of equipment, and stiff polyester filaments, etc., to achieve soft surface, long service life, improved quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

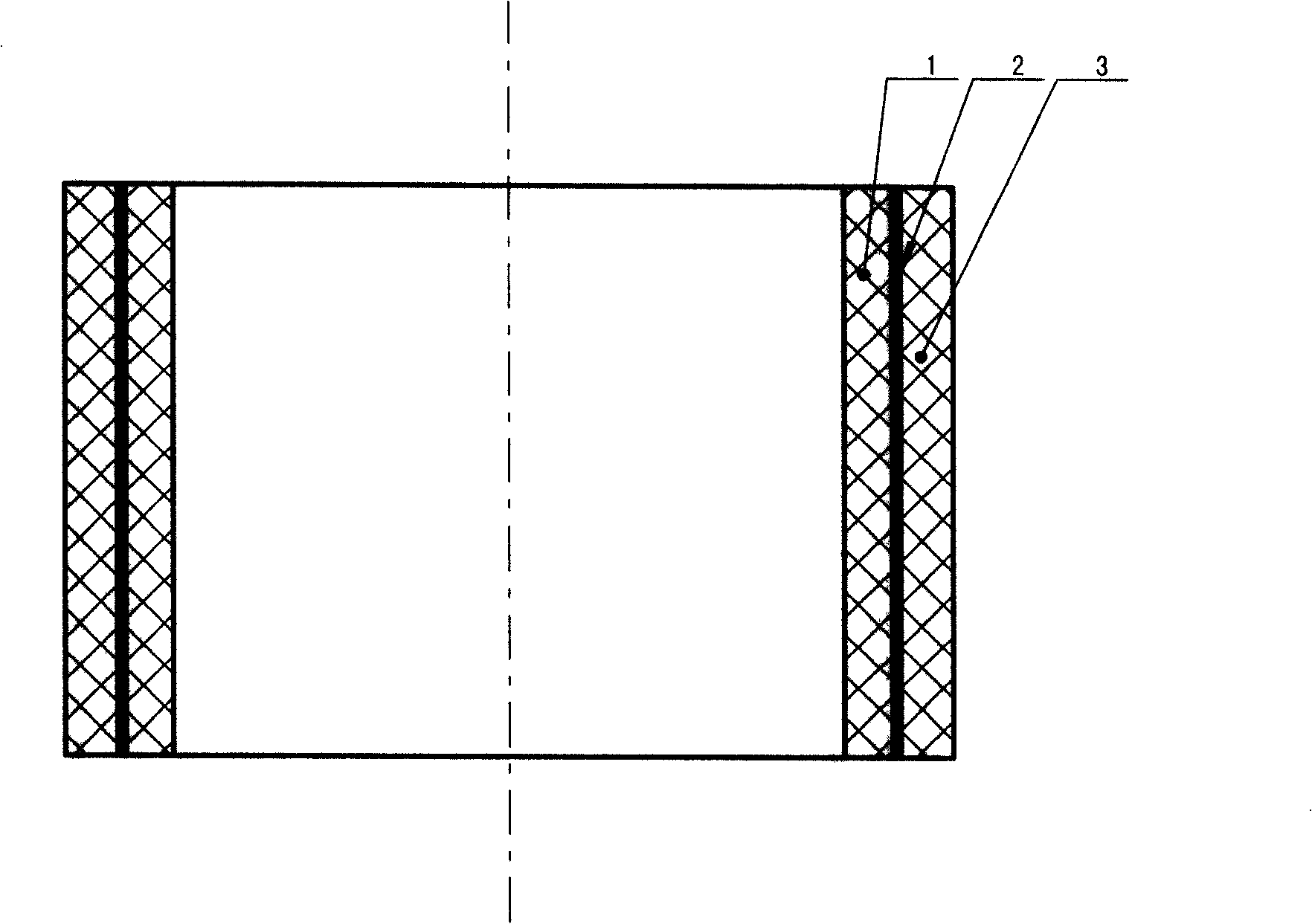

[0037] Such as figure 1 As shown, the high-speed spinning chemical fiber guide apron of the present invention is composed of an inner rubber apron 1, a core-spun yarn 2 and an outer rubber apron 3. The thickness and width of the high-speed spinning chemical fiber guide apron can be determined according to actual conditions. Need to adjust.

[0038] The rubber apron is made of polymer materials, and is manufactured using the following raw materials and their weight ratios:

[0039] Nitrile rubber NBR: 10kg, polyvinyl chloride HPVC: 4kg, dibutylcerium C-102: 0.18kg, polyurethane PU: 2kg, barium stearate: 0.12kg, zinc stearate: 0.02kg, antioxidant D : 0.1kg, stearic acid: 0.1kg, zinc oxide: 0.6kg, titanium dioxide: 0.5kg, white carbon black: 3kg, dibutyl fat: 1kg, colorant: red 0.2kg, yellow 0.1kg, accelerator: sulfur 0.25kg, Accelerator DM 0.3kg, Accelerator M 0.08kg.

[0040] The above-mentioned ratio of raw materials is used to manufacture high-speed spinning chemical fiber...

Embodiment 2

[0048] Embodiment 2: use following raw material and weight ratio thereof to manufacture:

[0049] Nitrile rubber NBR: 10kg, polyvinyl chloride HPVC: 7.8kg, dibutylcerium C-102: 0.28kg, polyurethane PU: 3kg, barium stearate: 0.2kg, zinc stearate: 0.04kg, antioxidant D: 0.2kg, stearic acid: 0.1kg, zinc oxide: 0.gkg, titanium dioxide: 0.9kg, white carbon black: 3kg, dibutyl fat: 1.8kg, colorant: red 0.2kg, yellow 0.1kg, promote Agent: sulfur 0.45kg, accelerator DM 0.4kg, accelerator M 0.05kg.

[0050] Its manufacture method is with embodiment 1.

Embodiment 3

[0051] Embodiment 3: use following raw material and weight ratio thereof to manufacture:

[0052] Nitrile rubber NBR: 10kg, polyvinyl chloride HPVC: 6kg, dibutylcerium C-102: 0.25kg, polyurethane PU: 3kg, barium stearate: 0.2kg, zinc stearate: 0.03kg, antioxidant D : 0.15kg, stearic acid: 0.1kg, zinc oxide: 0.6kg, titanium dioxide: 0.8kg, white carbon black: 3kg, dibutyl fat: 1.5kg, colorant: red 0.2kg, yellow 0.2kg, accelerator: Sulfur 0.4kg, Accelerator DM 0.3kg, Accelerator M 0.06kg.

[0053] Its manufacture method is with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com