Hydrogenation catalysts and its manufacturing method and use

A hydrogenation catalyst, catalyst technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve the problem that the adjustment measures for the number of acid centers and acid strength are not in place, and the catalyst selectivity is not strong. , large loss of anti-knock index, etc., to achieve the effect of effective maintenance of octane number, reduction of olefin saturation performance, and reduction of equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

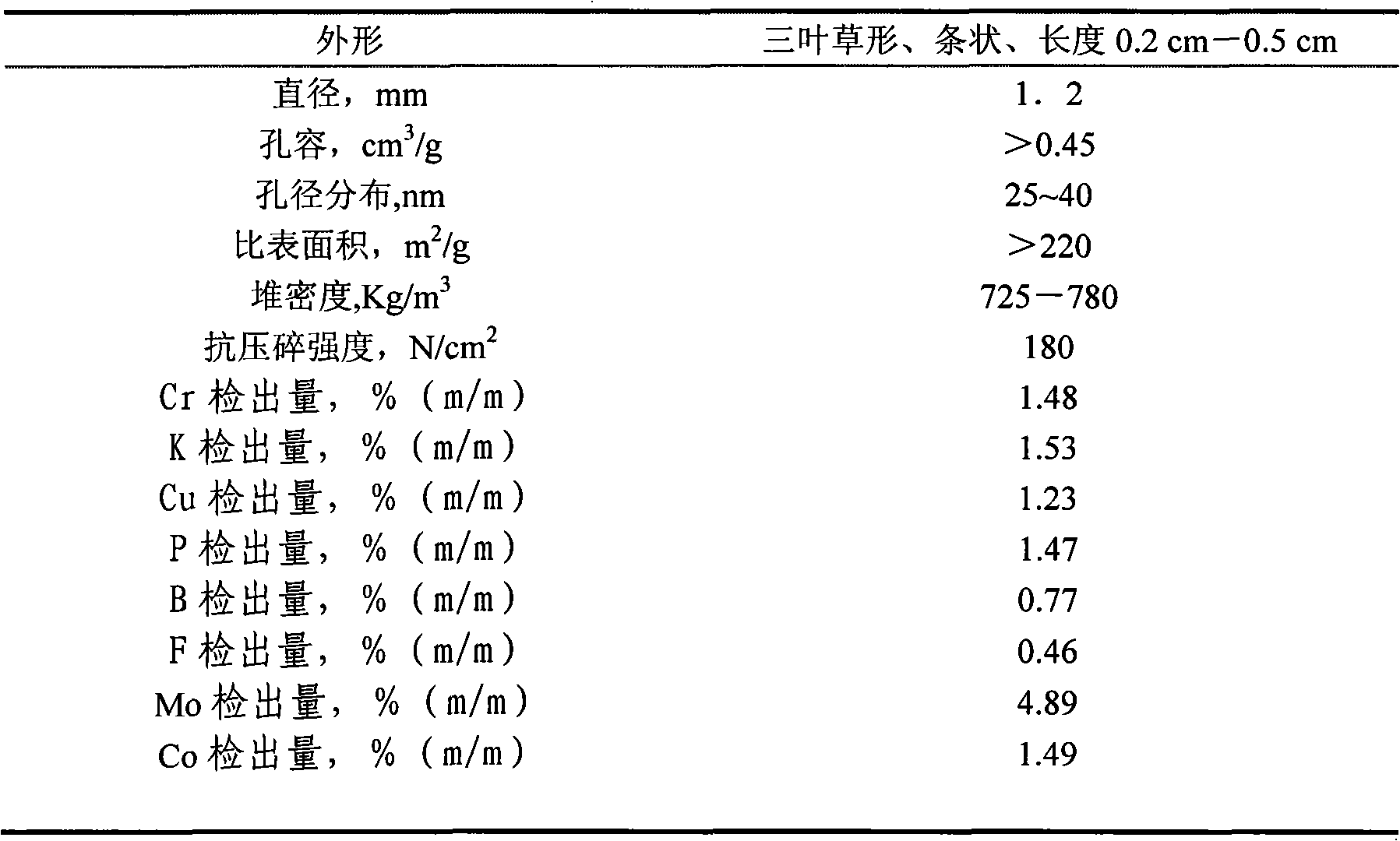

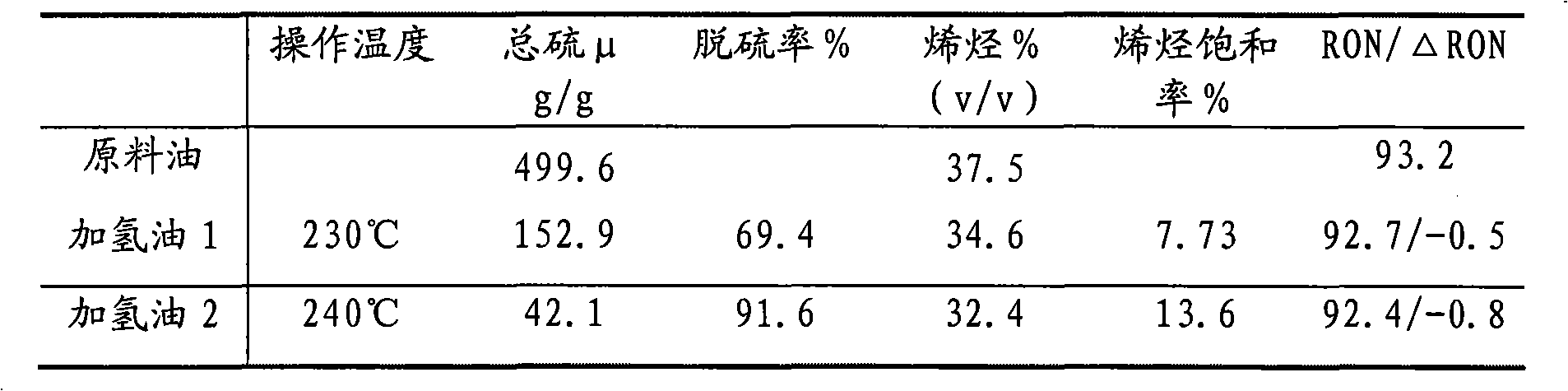

Embodiment 1

[0045] Preparation of hydrogenation catalyst

[0046] Step 1. The average particle diameter is 25nm and the average particle diameter is 250 μ m two kinds of alumina powders are mixed with the ratio of mass ratio 1: 8;

[0047] Step 2. Add 2.5% kale powder by mass to the aluminum oxide powder obtained in step 1, fully mix;

[0048] Step 3. in the aluminum oxide-squat mixed powder that step 2 obtains, add 48L deionized water for every 100kg alumina-squat mixed powder, and deionized water dissolves boric acid, phosphoric acid, ammonium fluoride and nitric acid reagent, wherein boric acid, The amounts of phosphoric acid and ammonium fluoride dissolved are based on the contents of B, P, and F elements in the final finished catalyst, respectively. The finished catalyst contains 0.8% B, 1.5% P, and 0.5% F; the concentration of nitric acid is 0.025% mol / L, after the reagent is fully dissolved and stabilized, add alumina-seed green mixed powder and knead, extrude into particles with ...

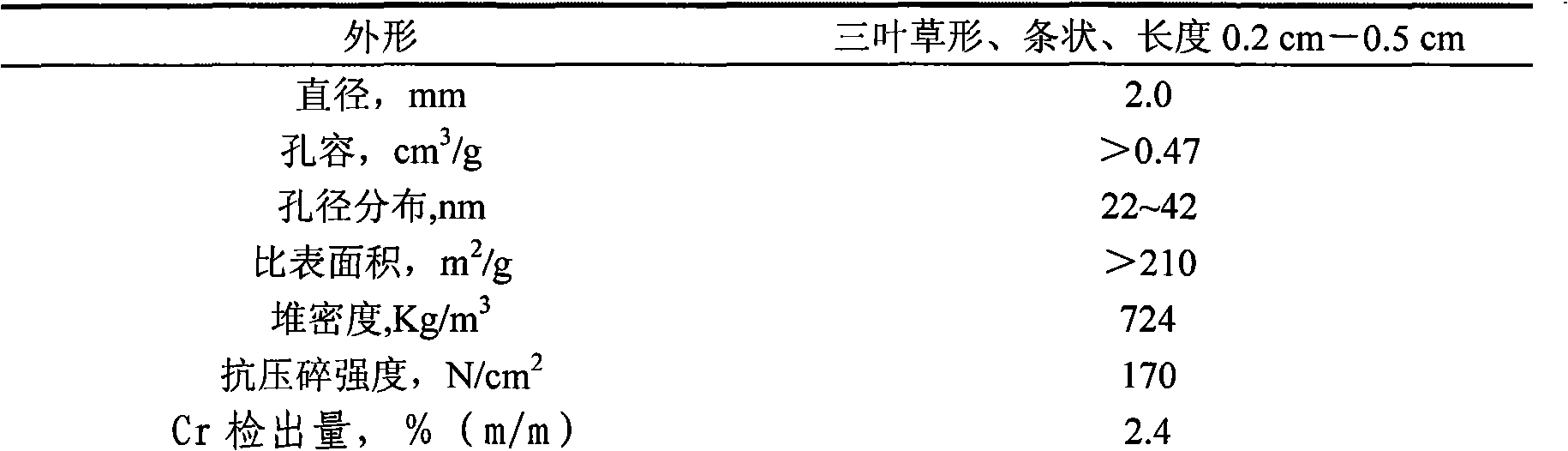

Embodiment 2

[0060] Preparation of hydrogenation catalyst

[0061] Step 1. The average particle diameter is 25nm and the average particle diameter is 250 μ m two kinds of alumina powders are mixed in the ratio of mass ratio 1: 12;

[0062] Step 2. Add 4.5% scallop powder by mass to the aluminum oxide powder obtained in step 1, fully mix;

[0063] Step 3. In the alumina-squat mixed powder obtained in step 2, add 52L deionized water for every 100kg of alumina-squat mixed powder, and dissolve boric acid, phosphoric acid, ammonium fluoride and nitric acid reagent in the deionized water, wherein boric acid , phosphoric acid, ammonium fluoride dissolved amount is based on the content of B, P, F elements in the final finished catalyst respectively, and containing B in the finished catalyst is 1.2%, P is 2.5%, and containing F is 1.0%; The concentration of nitric acid is 0.050mol / 1, after the reagent is fully dissolved and stabilized, add alumina-seed green mixed powder and knead, extrude into pa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com