High-strength earth work grille net

A geogrid, high-strength technology, used in soil protection, infrastructure engineering, excavation, etc., can solve the problems of non-UV resistance, inconvenient storage and transportation, and difficult to restore, achieve strong interlocking and occlusion, overcome the The effect of uneven settlement and overall performance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

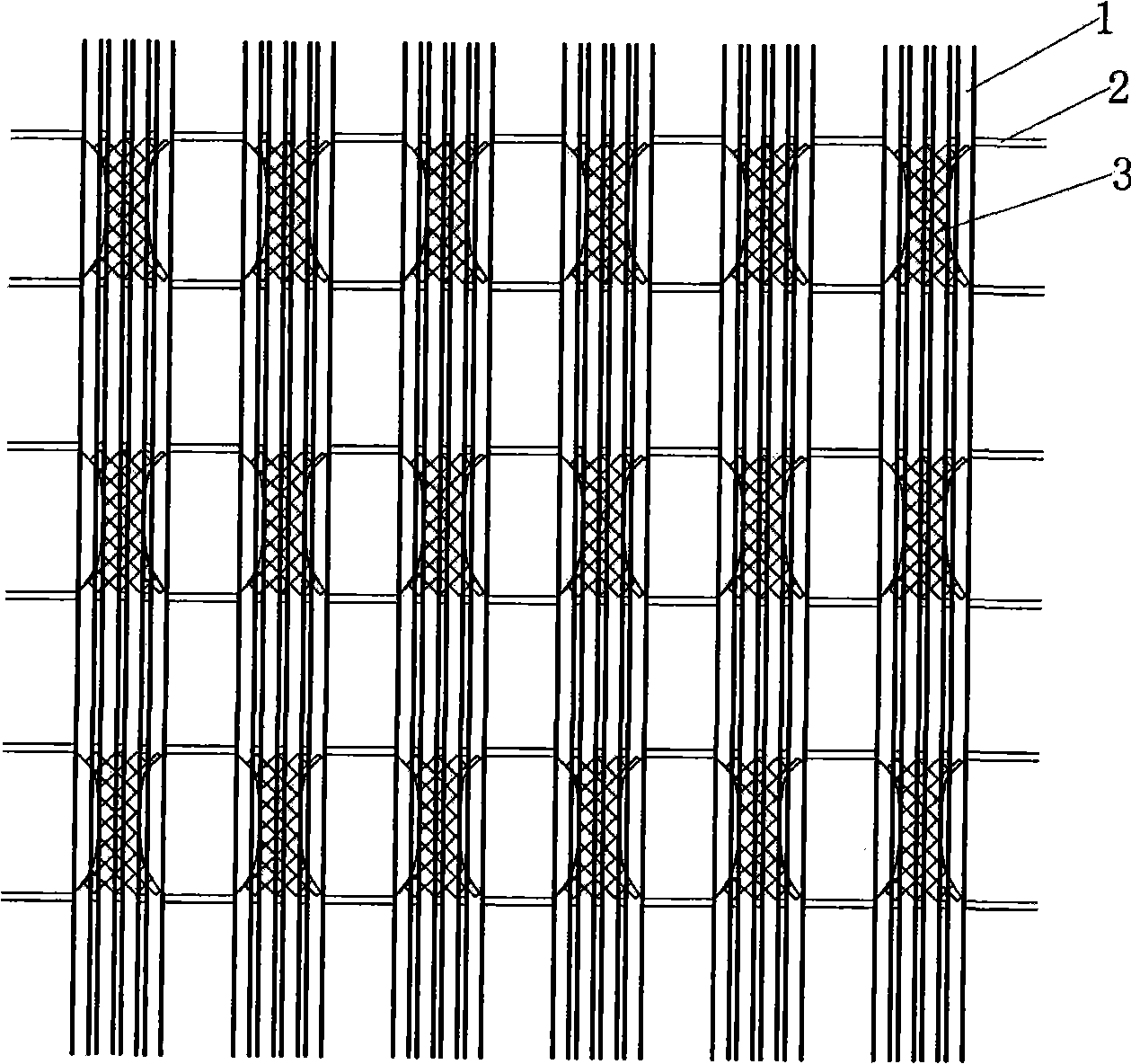

[0022] see figure 1

[0023] What is shown in the figure is a high-strength and high-modulus polyethylene grid net. The radial direction of the grid net is made of high-strength and high-modulus polyethylene fiber material, and the weft direction is made of conventional polyester fiber material. A plurality of conventional polyester fiber bundles 2 are woven into a net shape by a warp knitting directional loom. The mesh is quadrilateral, the side length is 35mm, and the width in the weft direction is 2-6 meters. The radial long distance can be produced according to the required length. The net is packed into round rolls along the radial direction to facilitate laying during use.

[0024] Each bundle of high-strength and high-modulus polyethylene fiber bundles in the radial direction of the grid net has four strands gathered together and bound by a warp-knitted net 3. Each strand is twisted with multiple high-strength and high-modulus polyethylene fiber filaments, and each str...

Embodiment 2

[0029] The warp and weft directions of the grid net are all braided by high-strength and high-modulus polyethylene fiber bundles, and the number and diameter of each bundle of fiber filaments and the size of the grid are determined according to requirements, and the rest are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com