Method for extracting blackberry pigment

A technology of pigment and blackberry, which is applied in the field of preparation of food coloring, can solve the problems of increased cost, blackberry berries are not resistant to storage and transportation, etc., and achieve the effects of stable structure, saving concentration time, and good thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

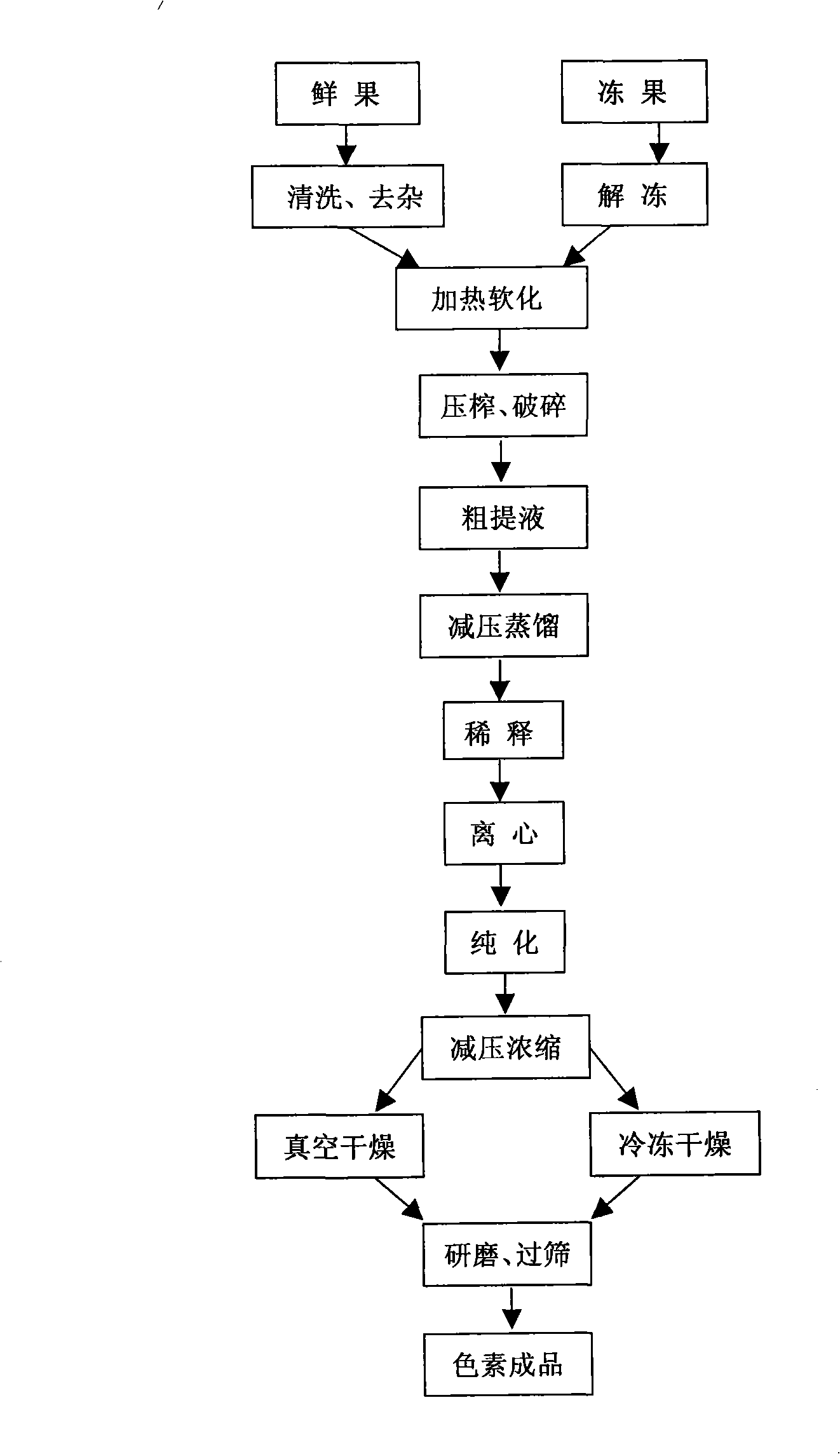

Method used

Image

Examples

Embodiment 1

[0044] Embodiment 1: Taking the fresh fruit of 1000kg blackberry variety Boysen as an example, the blackberry pigment is produced by vacuum drying.

[0045] (1) Fruit puree production: select 1000kg of fresh blackberry fruits that are completely mature or more than 9 mature without diseases and insect pests, rinse with an automatic spray fruit washing machine, wash away the dirt on the fruit surface, and manually remove impurities and inferior quality on the selection belt Fruits, drain the water, quickly heat the rinsed berries to 70-80°C in a hot and cold cylinder to soften the berries and inactivate enzymes, crush them with a crusher to produce fruit pulp, and quickly cool them to room temperature (about 25°C) ).

[0046](2) Pigment extraction: First add 2000L 1% HCL-70% alcohol extractant, mix well and extract at room temperature (about 25°C) for 1.5h, then squeeze and filter, and use 1000L 1% HCL-70% The alcohol was extracted once more, and the two extracts were mixed to...

Embodiment 2

[0049] Embodiment 2: Taking the frozen fruit of 1000kg blackberry variety Boysen as an example, blackberry pigment is produced by vacuum drying.

[0050] (1) Fruit puree production: After thawing the frozen fruit or directly putting the frozen fruit into the cold and hot cylinder and heating it quickly to 70-80°C to soften the berry and inactivate the enzyme, crush it with a crusher to produce the fruit puree, which is quickly Cool to room temperature (around 25°C).

[0051] (2) Pigment extraction: the operation is the same as in Example 1.

[0052] (3) Pigment purification: the operation is the same as in Example 1.

[0053] (4) Vacuum drying: the operation is the same as in Example 1.

Embodiment 3

[0054] Embodiment 3: take the fresh fruit of 1000kg blackberry variety Boysen as example, produce blackberry pigment by freeze-drying method.

[0055] (1) fruit puree production: operation is with embodiment 1.

[0056] (2) Pigment extraction: the operation is the same as in Example 1.

[0057] (3) Pigment purification: the operation is the same as in Example 1.

[0058] (4) Freeze-drying: place the obtained extract in a freeze dryer at a drying temperature of about -30°C to -40°C, and dry for 12 to 18 hours to obtain a dried powdery pigment. Grind and pass through a 100-mesh sieve to obtain 5.5 kg of powdery blackberry natural pigment. The processed pigment is immediately put into a brown bottle, sealed, dried, and stored at low temperature. This pigment can be stored for several years without deterioration under the condition of dryness and 0-4°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com