Laser auxiliary activity welding method

A welding method and laser-assisted technology, used in laser welding equipment, welding equipment, arc welding equipment, etc., can solve the problems of complex welding process, affecting the corrosion resistance of the weld, and slag on the surface of the weld.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

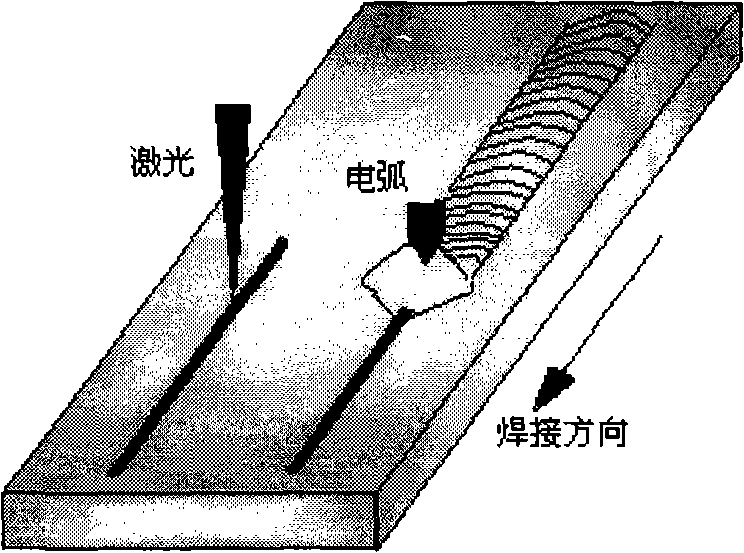

[0012] The material used is SUS 304 stainless steel. Before welding, carefully clean the weld bead with sandpaper. First, use 50W CO 2 The laser beam melts the surface of the weldment under the protection of oxygen, increasing the oxygen content of the weld surface. In order to compare the change of penetration depth with and without low-power laser treatment, only half of the sample was melted, such as figure 1 shown. The process parameters of low-power laser melting are shown in Table 1. Then use conventional TIG welding to cover the low-power laser pretreatment area, and complete the welding of the low-power laser pretreatment area and the non-laser treatment area at one time. The welding parameters are shown in Table 2. The automatic argon arc welding device was used in the test, the argon arc welding torch was fixed, and the workpiece was placed on a horizontally movable work platform, so as to ensure that the arc length did not change during the welding process, thereb...

Embodiment 2

[0017] The material used in the test is SUS 304 stainless steel, the sample size is 200mm×80mm×8mm, and the weld bead is carefully cleaned with sandpaper before welding. The method of low-power laser treatment is identical with embodiment 1, adopts conventional CO 2 Laser welding covers the low-power laser pretreatment area, conventional CO 2 The parameters of laser welding are shown in Table 5.

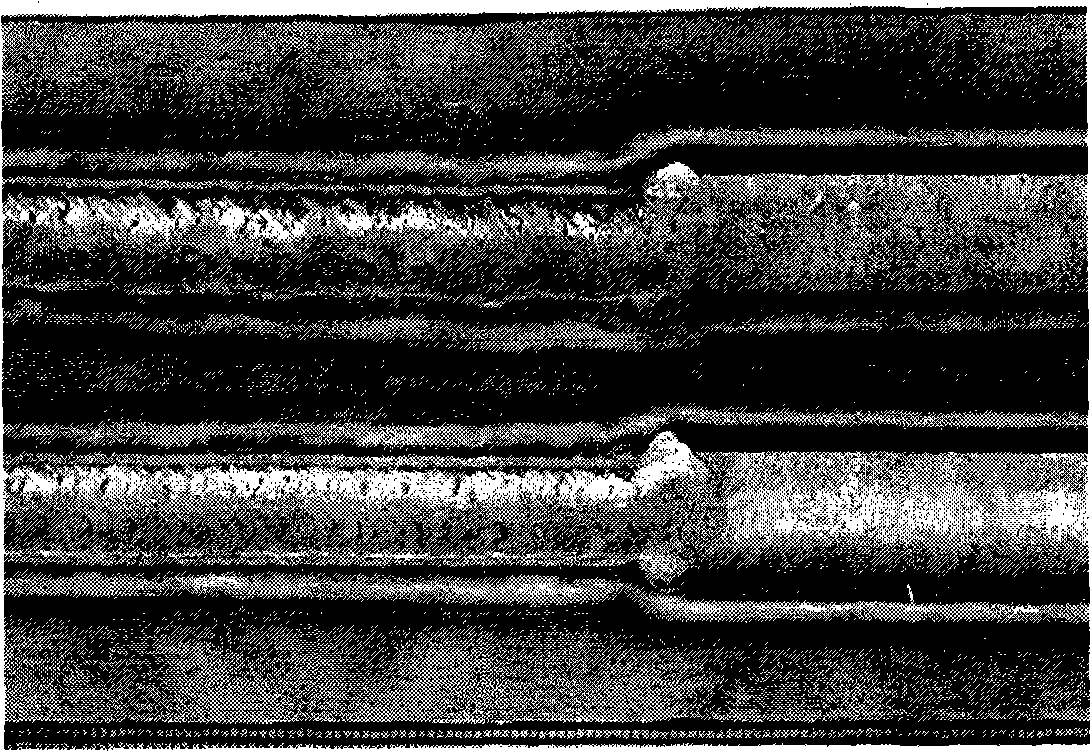

[0018] Under the same laser welding specification, the penetration depth of the laser treatment area is increased by 1mm compared with the non-laser treatment area. Such as Image 6 , Figure 7 As shown, the weld width at the top of the weld in the laser treatment area is significantly smaller than that in the non-laser treatment area. Analyzing the oxygen content in the weld, the oxygen content of the weld without low-power laser treatment is 36ppm, and the oxygen content of the weld with low-power laser treatment is 98ppm, which is within the allowable use range of the material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com