Optical waveguide containing Cu ion

A technology of optical waveguide and multi-mode optical waveguide, which is applied in the direction of optical waveguide and light guide, and can solve the problem of slow diffusion of Cu ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

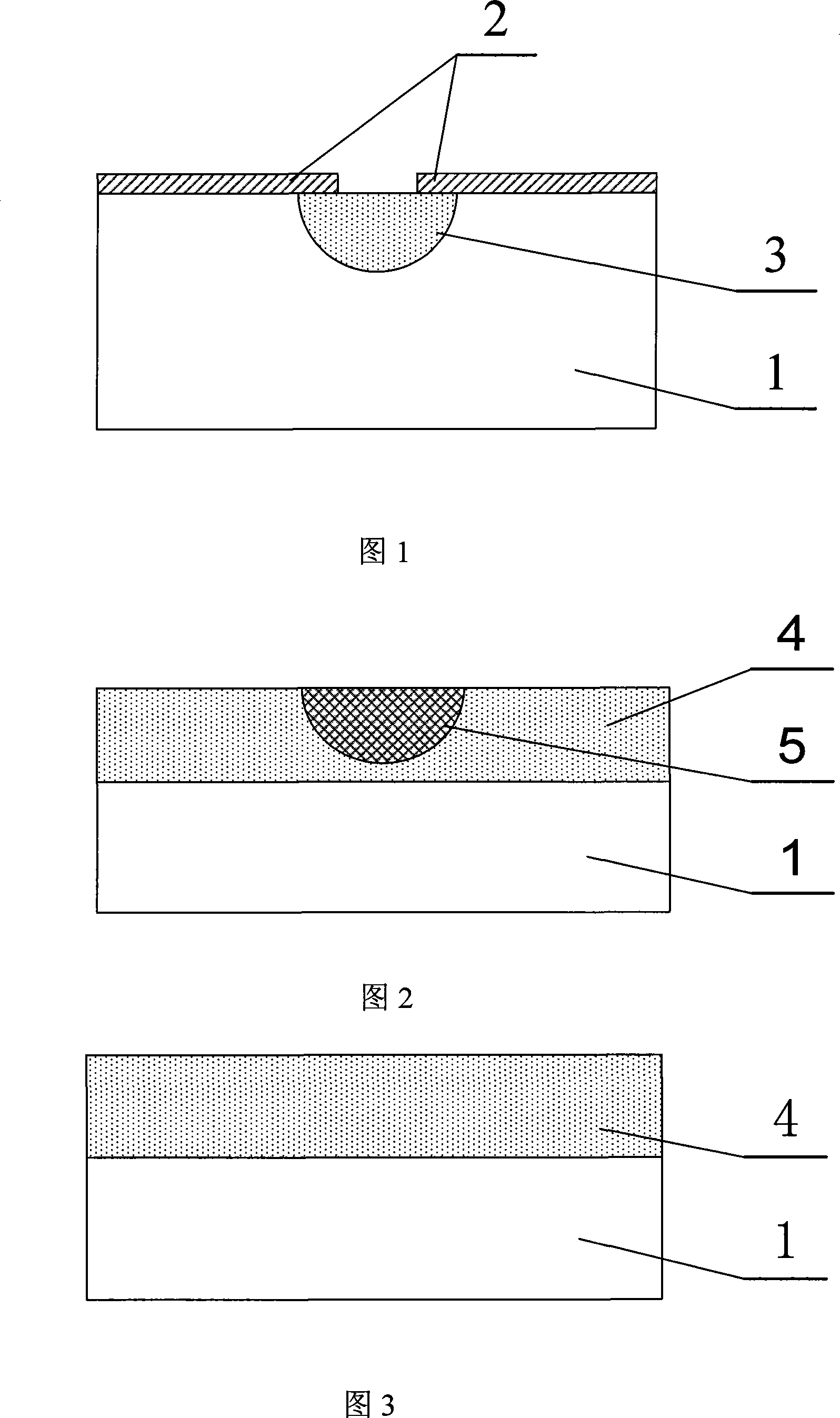

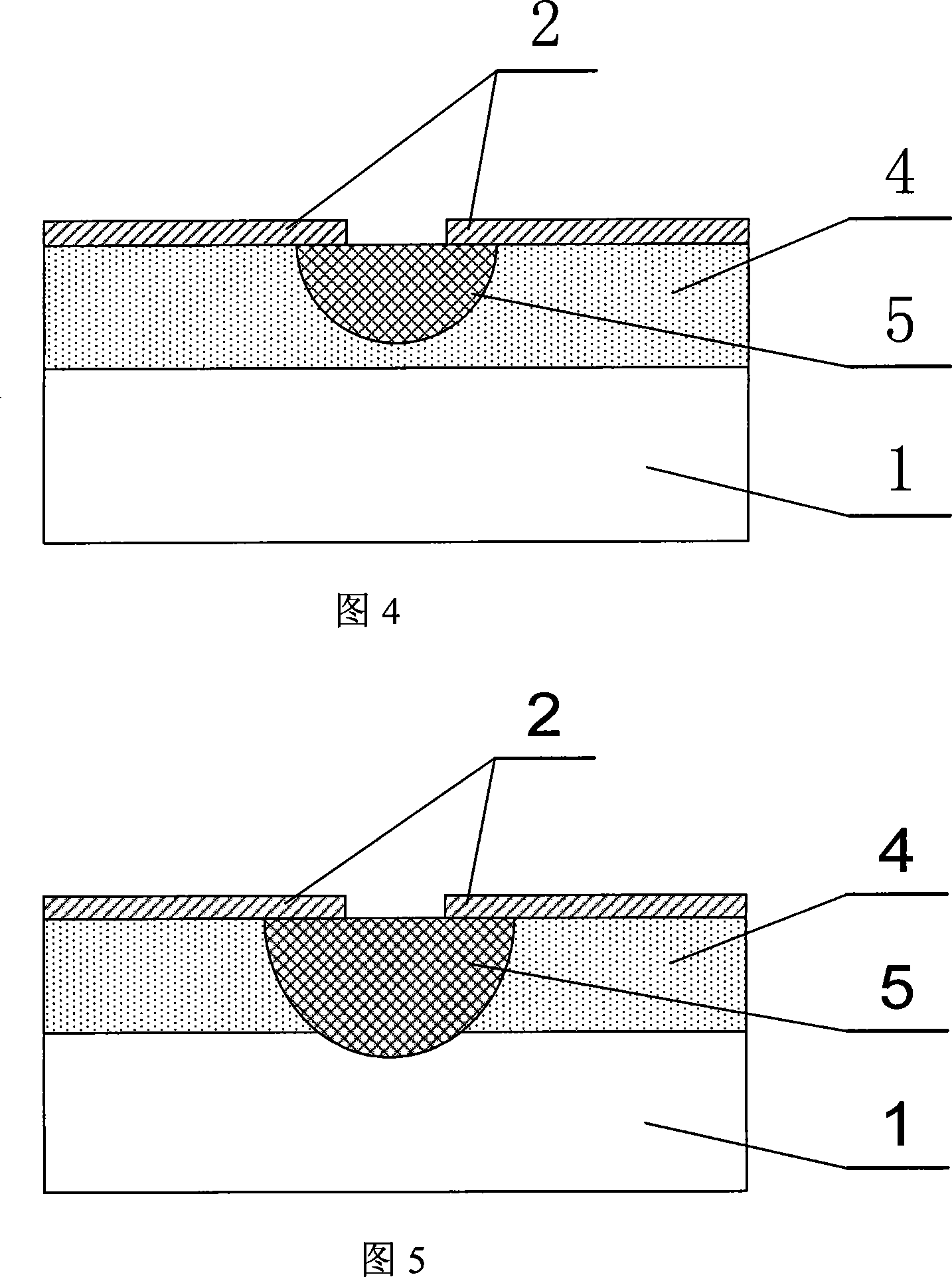

[0022] As shown in Fig. 2 and Fig. 4, the present invention is provided with planar Cu ion diffusion region 4 on the upper surface of glass substrate 1, is provided with strip-shaped high polarizability ion diffusion region 5 in planar Cu ion diffusion region 4, As the core layer of the optical waveguide, the refractive index of the strip-shaped high polarizability ion diffusion region 5 is higher than that of the glass substrate 1 and also higher than that of the plate-shaped Cu ion diffusion region 4 .

[0023] The material of the glass substrate 1 is silicate glass, borate glass or phosphate glass.

[0024] The high polarizability ion is Ag + , Tl + 、Cs + , Li + or Rb + ion.

[0025] The optical waveguide is a single-mode optical waveguide or a multi-mode optical waveguide.

[0026] The thickness of the strip-shaped high polarizability ion diffusion region 5 is smaller than the thickness of the flat Cu ion diffusion region 4 , or greater than the thickness of the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com