Sampler for locating and sampling ceramic filament

A sampler and single-fiber technology, which is applied in the field of positioning sampling and sampler for ceramic single-fiber high-temperature heat treatment, can solve the problems of poor reproducibility and accuracy, and achieve error reduction, simple structure, position reproducibility and accuracy high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The structure and working principle of the present invention will be described in detail below in conjunction with the accompanying drawings.

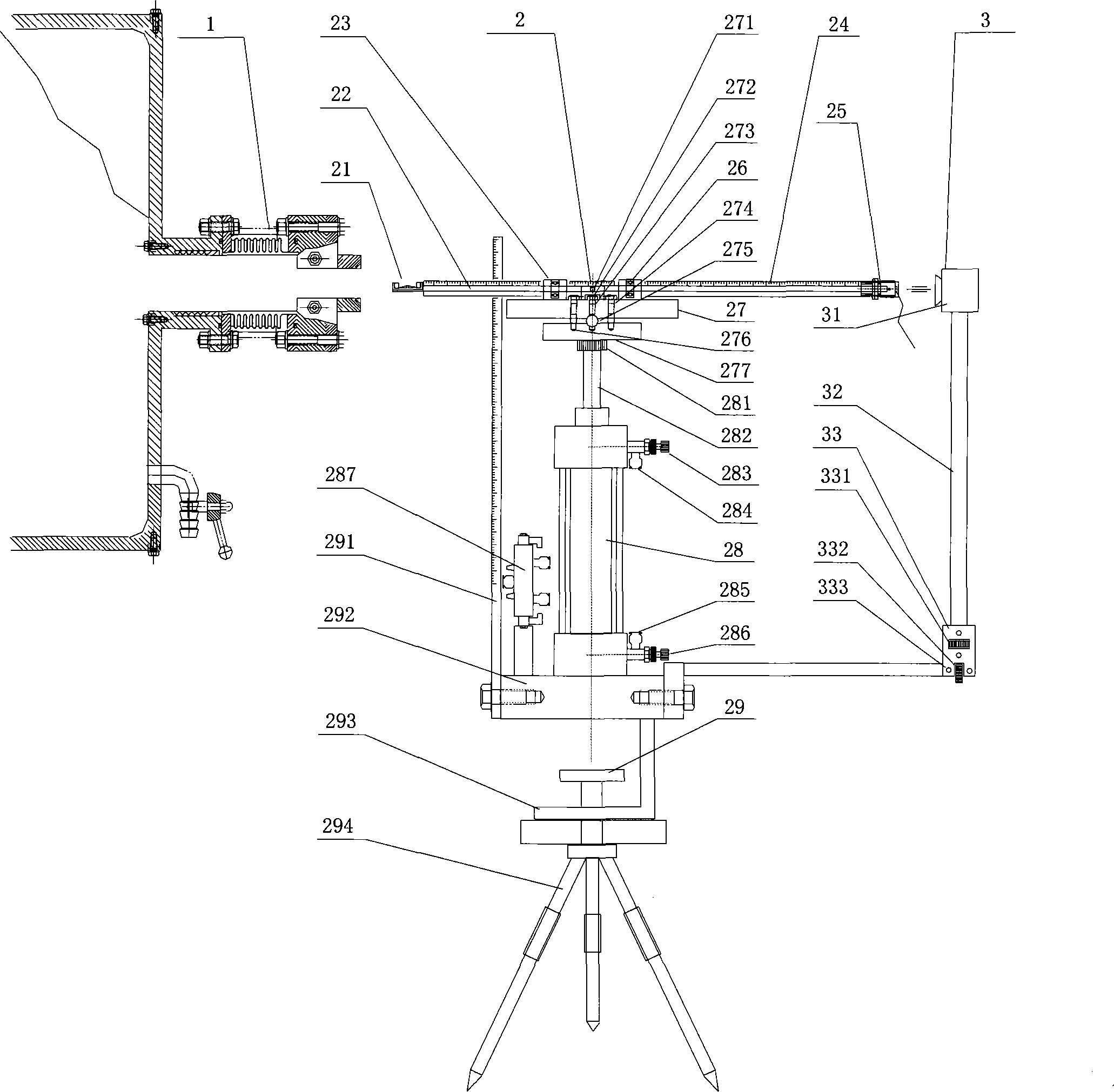

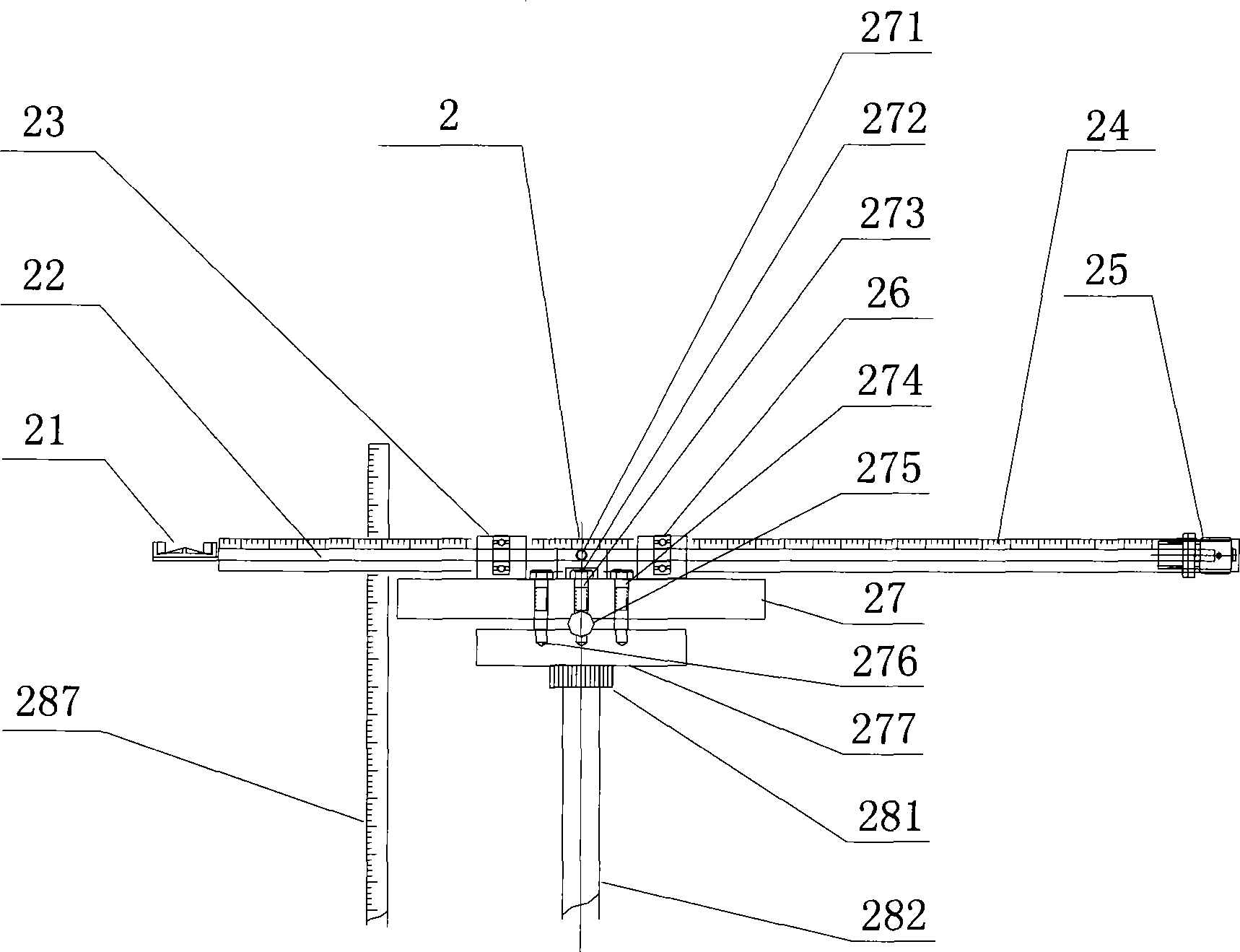

[0035] see Figure 1~4 , a positioning sampler for ceramic single fiber, including a sampler 2 and a high-precision optical level positioner 3 in two parts.

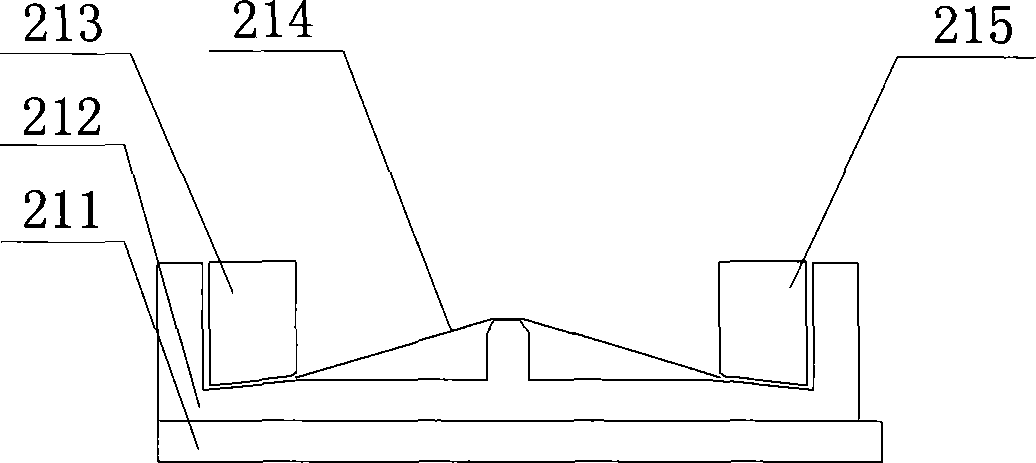

[0036] The sampler 2 is provided with a sample loading platform 21, a telescopic arm 22, bearing devices 23, 26, a guide rail 24, a driving mechanism 25, a square horizontal platform 27, a cylinder 28 and a base 29. The sample loading table 21 is located on the left side of the telescopic arm 22 and is welded horizontally with the telescopic arm 22 to play the role of carrying fiber samples. Telescopic arm 22, bearing device 23 and guide rail 24 are connected by driving mechanism 25, and are fixed on the square horizontal platform 27, and telescopic arm 22 penetrates and is close to bearing device 23, can slide. The telescopic arm 22 acts as a sample feeding guide rod, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com