Dual inside-and-outside ring capacitance sensor and two-phase flow speed related measuring system

A capacitive sensor and annular capacitor technology, applied in the field of flow velocity measurement of two-phase fluids, can solve the problems of not fundamentally solving problems, uneven distribution of electric field, affecting measurement accuracy, etc., to achieve easy on-site application, improve real-time performance and accuracy improve the accuracy of analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

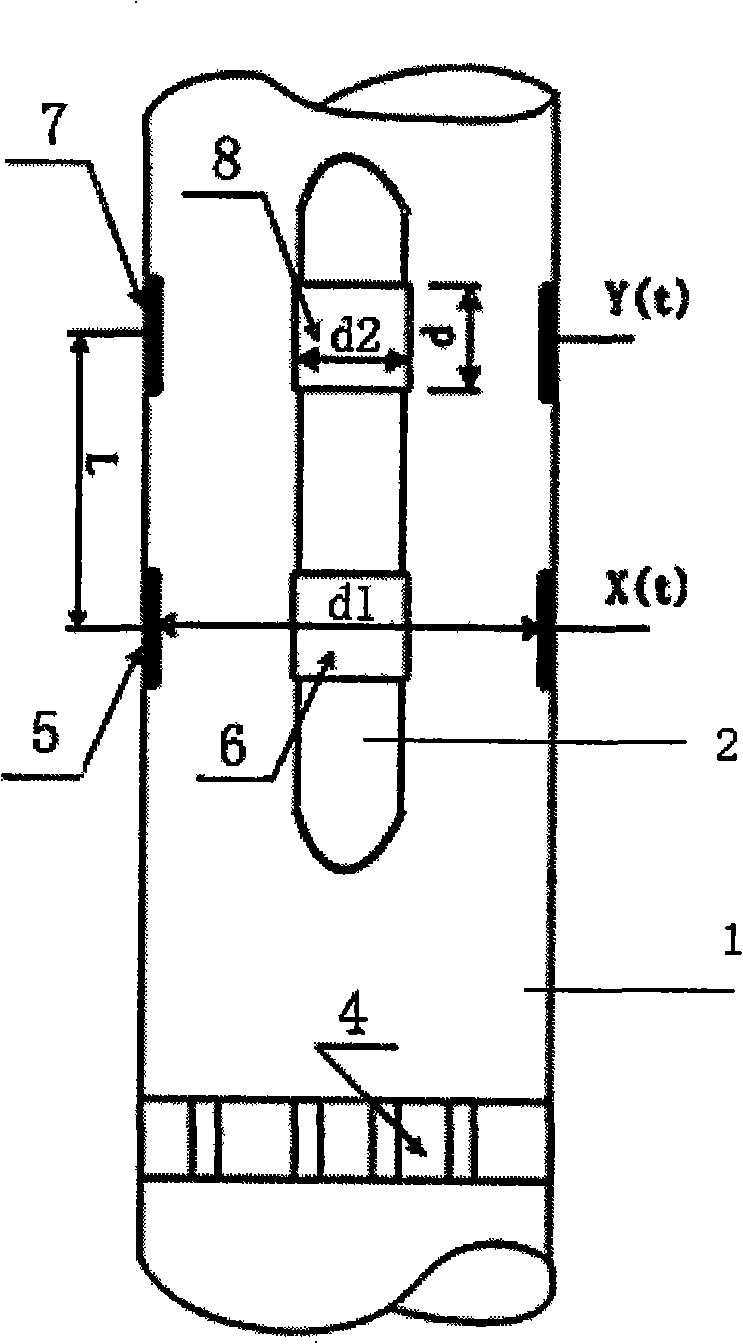

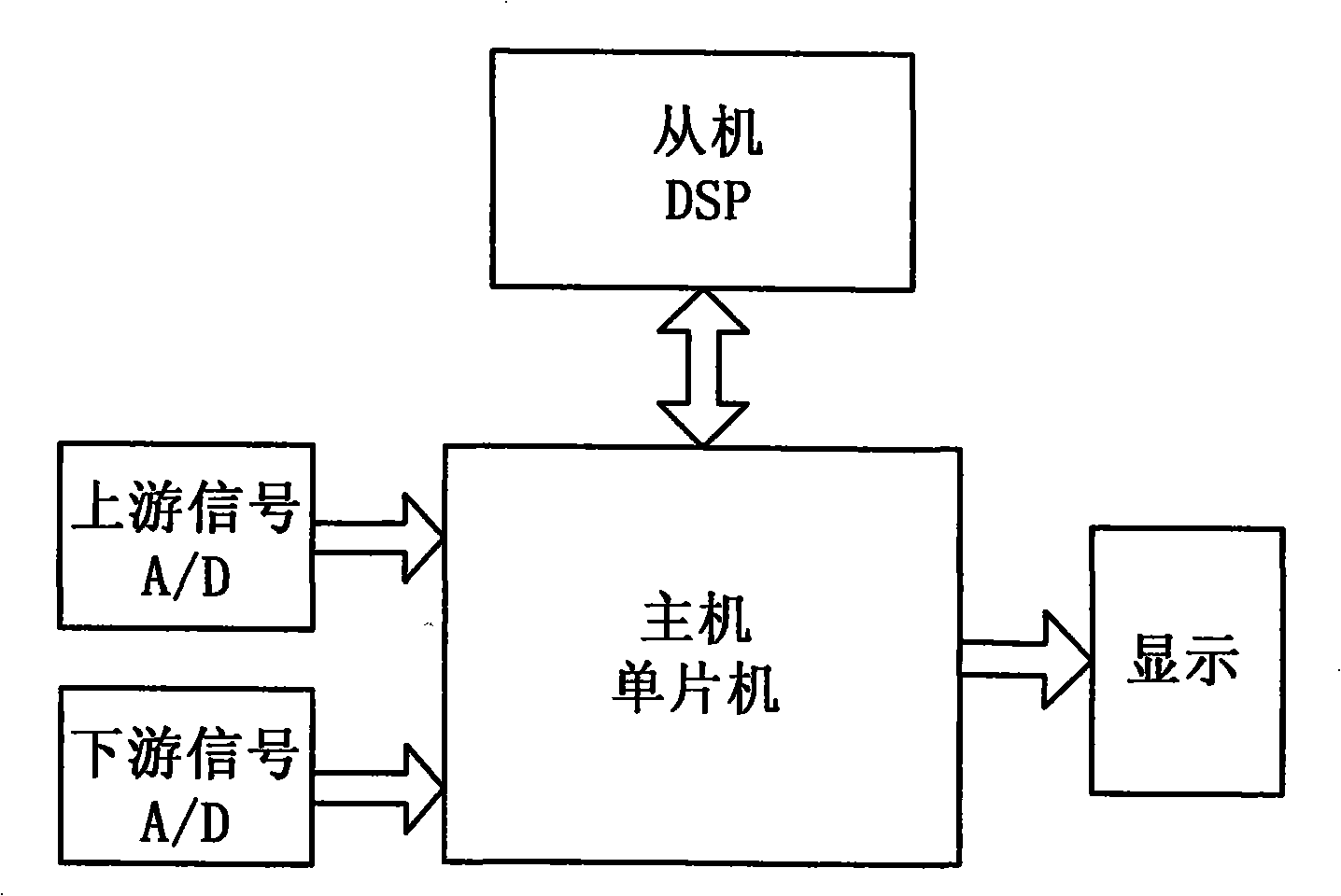

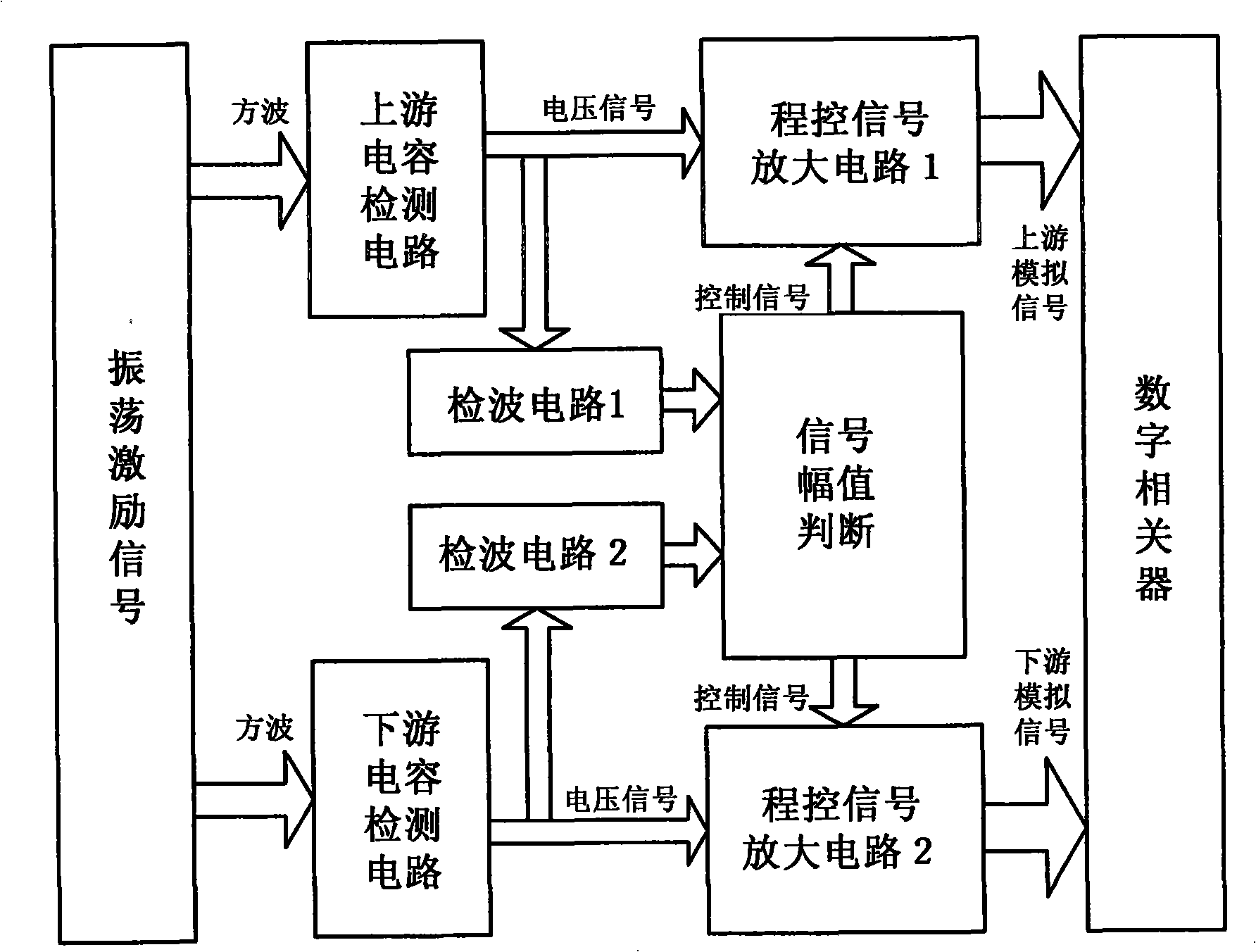

[0025] The structural principle of the present invention will be described below with reference to the accompanying drawings. Flow rate measurement double inner and outer ring capacitive sensors such as figure 1 shown. Gas-liquid, gas-solid, liquid-solid, liquid-liquid and other two-phase fluids enter the flow rate measurement double inner and outer annular capacitive sensors, and the fluid enters the upstream annular capacitive sensor after being rectified by the static mixer 4 set at the entrance of the measuring pipeline 1 On the double inner and outer ring capacitive sensor formed with the downstream ring capacitive sensor. The two inner ring electrodes 6 and 8 of the double inner and outer ring capacitive sensor are attached to the cylindrical electrode carrier 2 respectively, and the two outer ring electrodes 5 and 7 are attached to the inner wall of the measuring pipe 1 respectively. The electrode widths of the upper and lower capacitive sensors are both d=8mm, the di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com