Rack-and-pinion type slewing equipment of coal-excavating development machine

A technology of rack and pinion and slewing device, which is applied in the direction of driving device, transmission device, fluid transmission device, etc., and can solve the problems of weak bearing capacity, large slewing torque, poor stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with accompanying drawing:

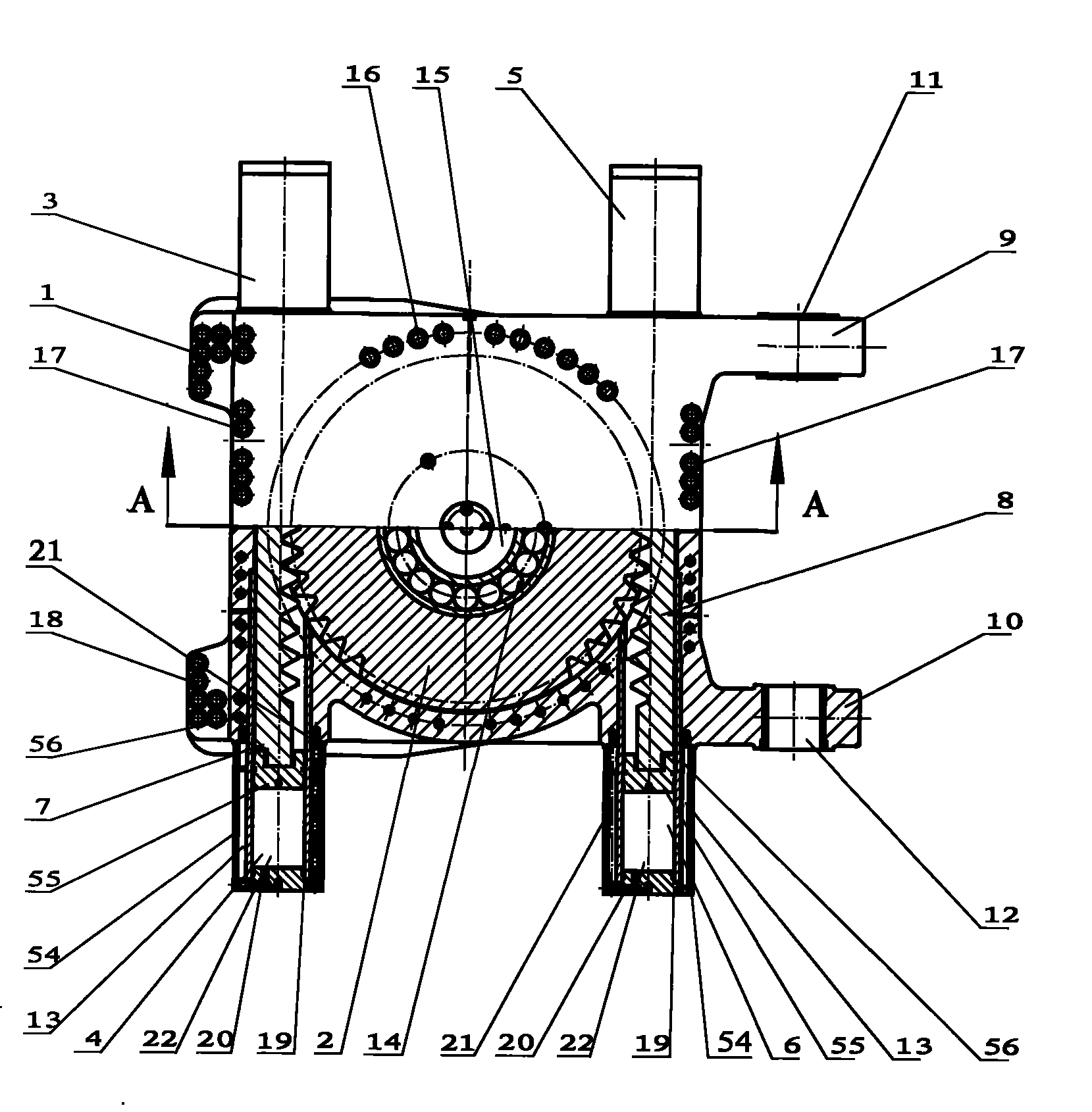

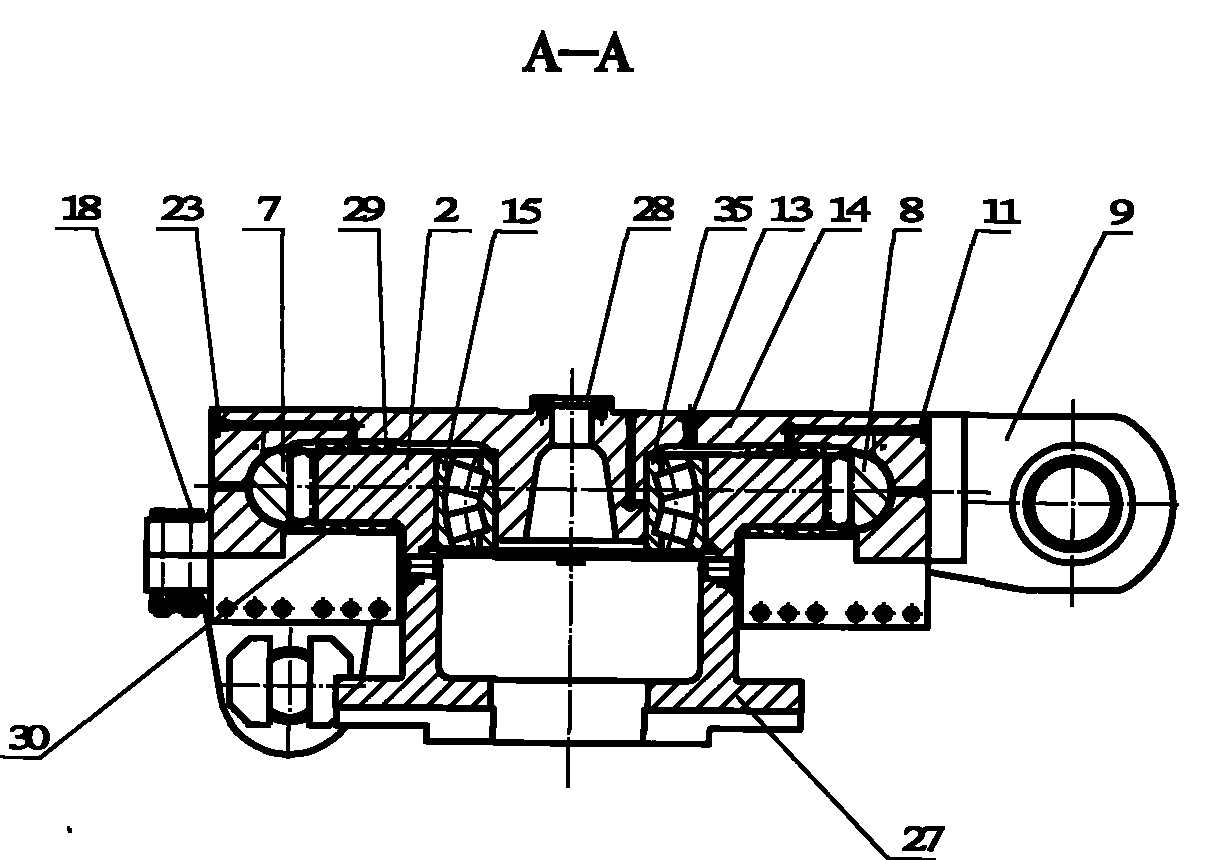

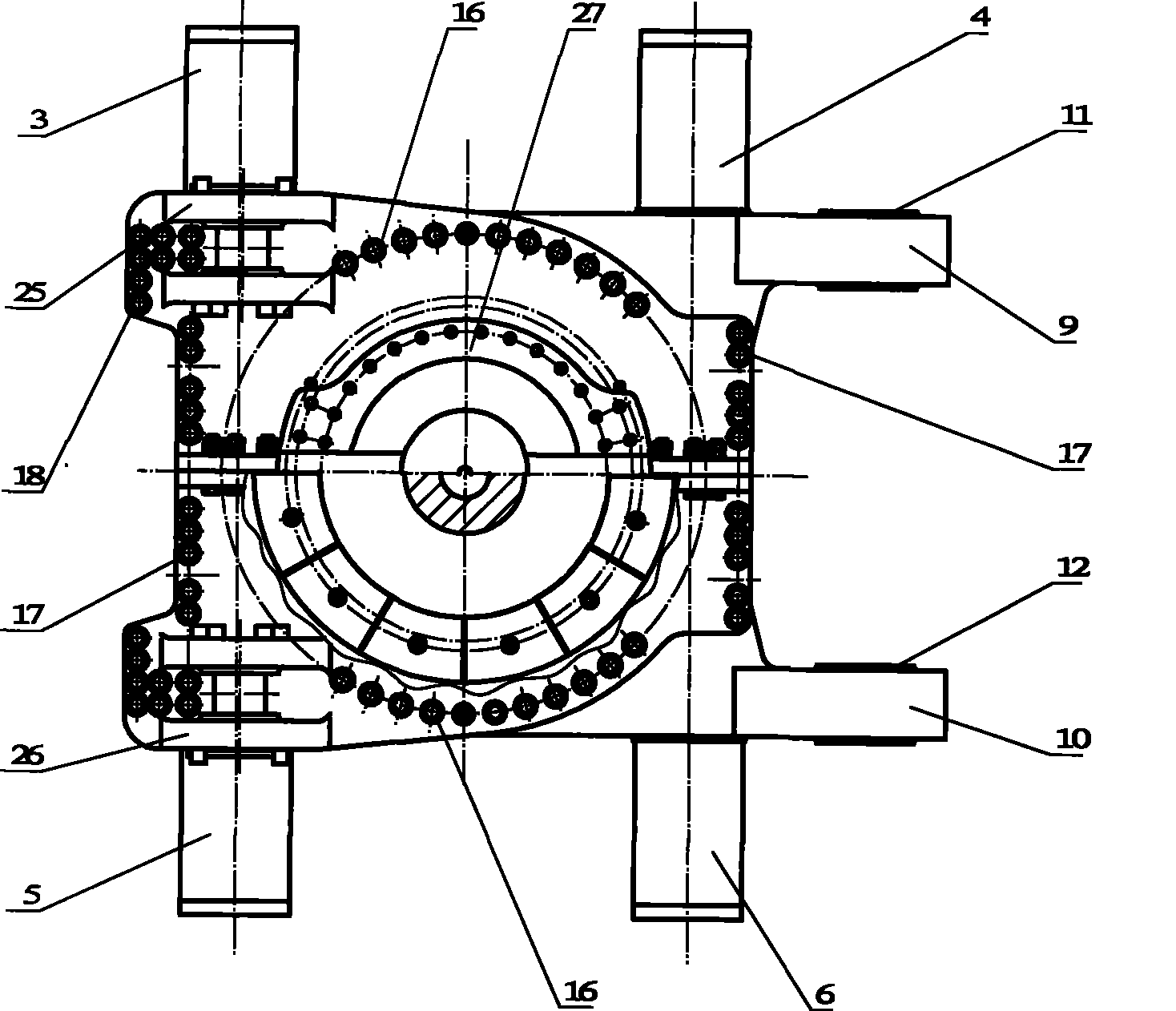

[0041] figure 1 , 2 , 3 shows the overall structure diagram of the rotary device, which is based on the rotary body 1, with a rotary gear 2 in the middle, left and right rotary racks 7, 8 on both sides of the rotary gear 2, rotary gear 2 and rotary gear Bars 7 and 8 are meshed and connected, with the rotary gear 2 as the center, symmetrically rotate left and right, the half angle of rotation is 26 °, and the full angle is 52 °, so as to adapt to the area needs of the left and right reciprocating mining of the coal mining roadheader.

[0042] Left and right revolving racks 7 and 8 have the same specifications as slewing gear 2, both have a modulus of 32, and a pressure angle of 28°. The meshing is tight and the transmission force is large, so as to adapt to the high-power needs of the harsh environment of the coal mine.

[0043] The two ends of the left and right rotary ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com