Invisuable veneer board type connecting mechanism

A connecting device and splint-type technology, which is applied in the direction of building components, walls, buildings, etc., can solve the problem of limiting the application range of point-supported glass curtain walls and glass daylighting roofs, high sealing requirements for the joints between glass panels and supporting plates, and increasing curtain wall And lighting roof cost and processing cycle and other issues, to achieve the effect of convenient and quick installation, compact structure and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

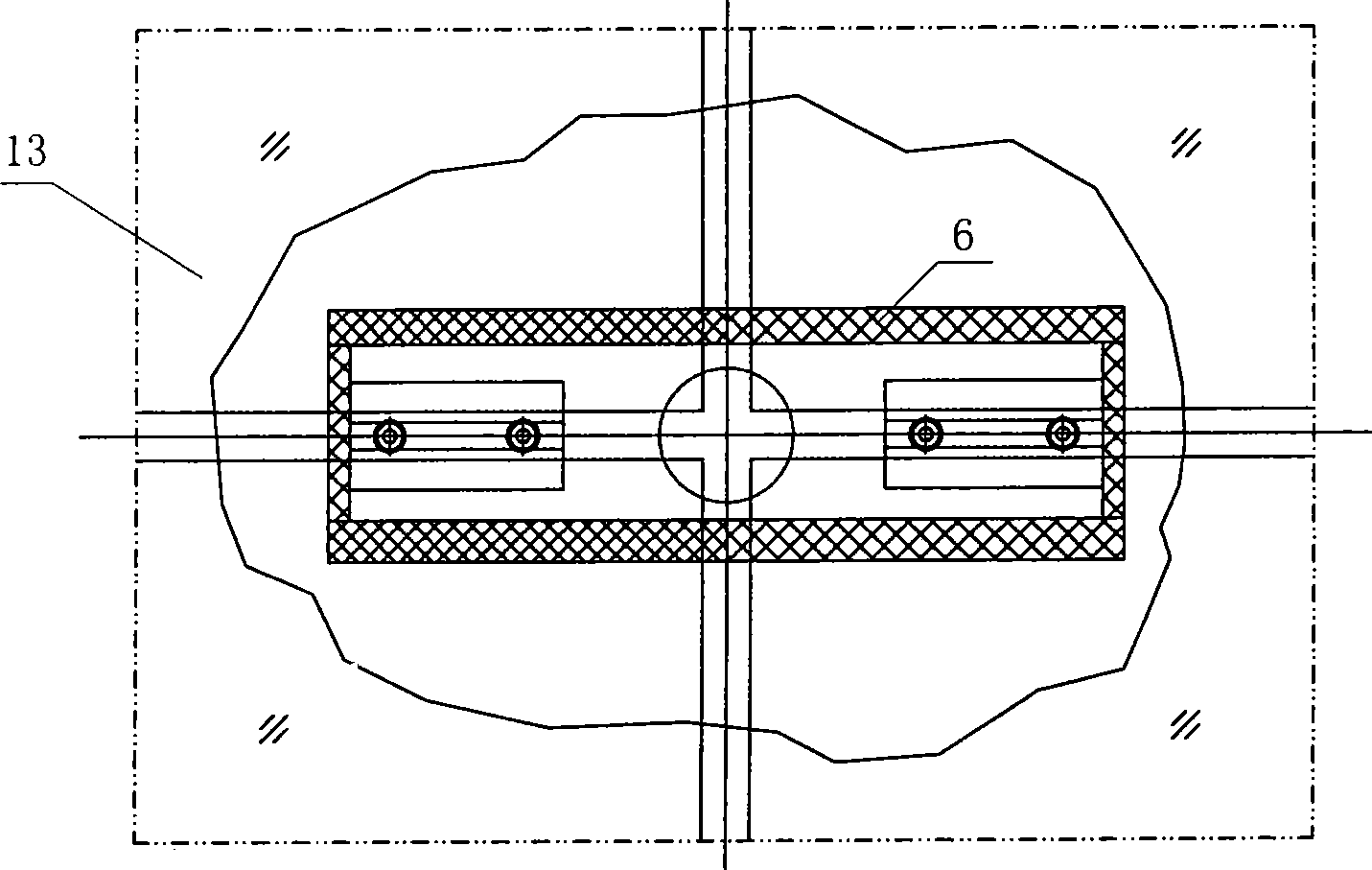

[0036] The female seat (nut seat) 1 is installed on the support structure, and the 2-1 screw rod of the adapter 2 is screwed into the screw hole 1-1 of the female seat (nut seat) 1 . Have oblong hole 6-1 on the support plate 6-2 of supporting plate part 6, oblong hole 6-1 corresponds to the circular hole 2-3 of adapter 2, inserts bearing pin 3, fixes with locking nut 4 again. The supporting plate part 6 can rotate and can have horizontal displacement. After the position is adjusted correctly, use the set screw 5 to fix it through the threaded hole 2-4 of the adapter 2. The support plate 6-2 is provided with a groove 6-3, the groove 6-3 is equipped with a rubber pad 7, the support plate 6-2 is provided with a supporting plate 6-5, and a soft glass spacer 11 is installed on the hollow glass 13. After installation, the pressing plate 9 is pressed on the built-in aluminum groove 12 of the insulating glass 13 . The round hole 9-1 of the pressing plate 9 penetrates the set screw 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com