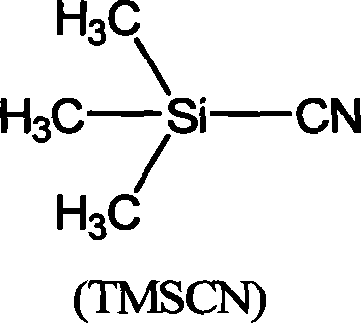

Method for preparing trimethylsilylcyanation

A technology of trimethylsilicon cyanide and halogenated trimethylsilane is applied in the field of preparation of high-efficiency trimethylsilicon cyanide, can solve problems such as environmental hazards, high cost, unfavorable operation, etc., achieves a green process method, reduces waste acid Hazard, operational hazard reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

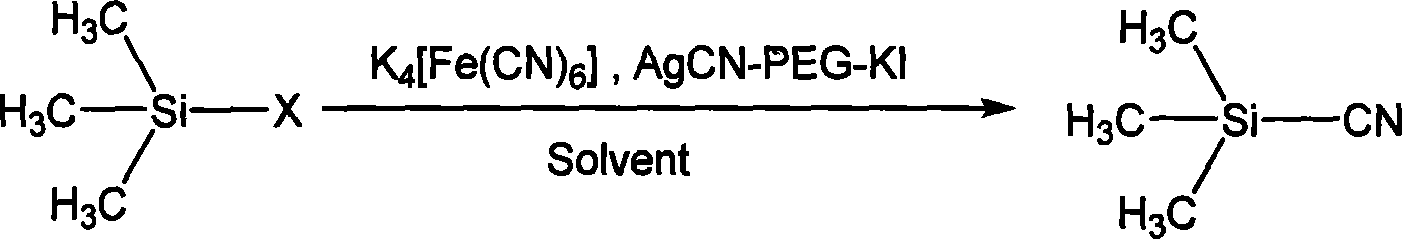

[0018] Embodiment 1: prepare trimethylsilyl cyanide by trimethylchlorosilane

[0019] Chlorotrimethylsilane (6.3 mL, 50 mmol), potassium ferrocyanide (19.15 g, 50 mmol), silver cyanide (0.67 g, 5 mmol), polyethylene glycol 200 (1.0 g, 5 mmol), potassium iodide (0.9 g , 5 mmol) was dissolved in N, N-dimethylformamide (250 ml), and reacted under reflux at 200° C. for 12 hours with stirring. Ethyl acetate (50-80 ml) was added, insolubles were removed by filtration, the organic phase (20 ml) was washed with water, dried over anhydrous magnesium sulfate, and 3.5 ml of trimethylsilylcyanide was obtained by rotary evaporation of the solvent.

Embodiment 2

[0020] Embodiment 2: prepare trimethylsilyl cyanide by bromotrimethylsilane

[0021] Bromotrimethylsilane (6.6 ml, 50 mmol), potassium ferrocyanide (3.83 g, 10 mmol), silver cyanide (0.2 g, 1.5 mmol), polyethylene glycol 400 (0.8 g, 2 mmol), potassium iodide (0.27 g, 1.5mmol) was dissolved in toluene (150ml), and stirred at reflux for 6 hours at 120°C. Ethyl acetate (60-90 ml) was added, insolubles were removed by filtration, the organic phase (20 ml) was washed with water, dried over anhydrous magnesium sulfate, and 5 ml of trimethylsilylcyanide was obtained by rotary evaporation of the solvent.

Embodiment 3

[0022] Embodiment 3: prepare trimethylsilyl cyanide by iodotrimethylsilane

[0023] Iodotrimethylsilane (7.1 mL, 50 mmol), potassium ferrocyanide (1.92 g, 5 mmol), silver cyanide (0.4 g, 3 mmol), polyethylene glycol 1000 (2.0 g, 2 mmol), potassium iodide (0.27 g , 1.5mmol) was dissolved in benzene (200ml), and stirred at reflux at 40°C for 2 hours. Ethyl acetate (70-100 ml) was added, insolubles were removed by filtration, the organic phase (20 ml) was washed with water, dried over anhydrous magnesium sulfate, and 6.5 ml of trimethylsilylcyanide was obtained by rotary evaporation of the solvent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com