Pipe pile steam test maintenance residual heat utilization and reutilization sulfur dioxide desulfurization technology

A technology of sulfur dioxide and pipe piles, which is applied in the directions of preheating, steam generation, feed water heater, etc., to achieve the effects of remarkable economic benefits, simple equipment and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

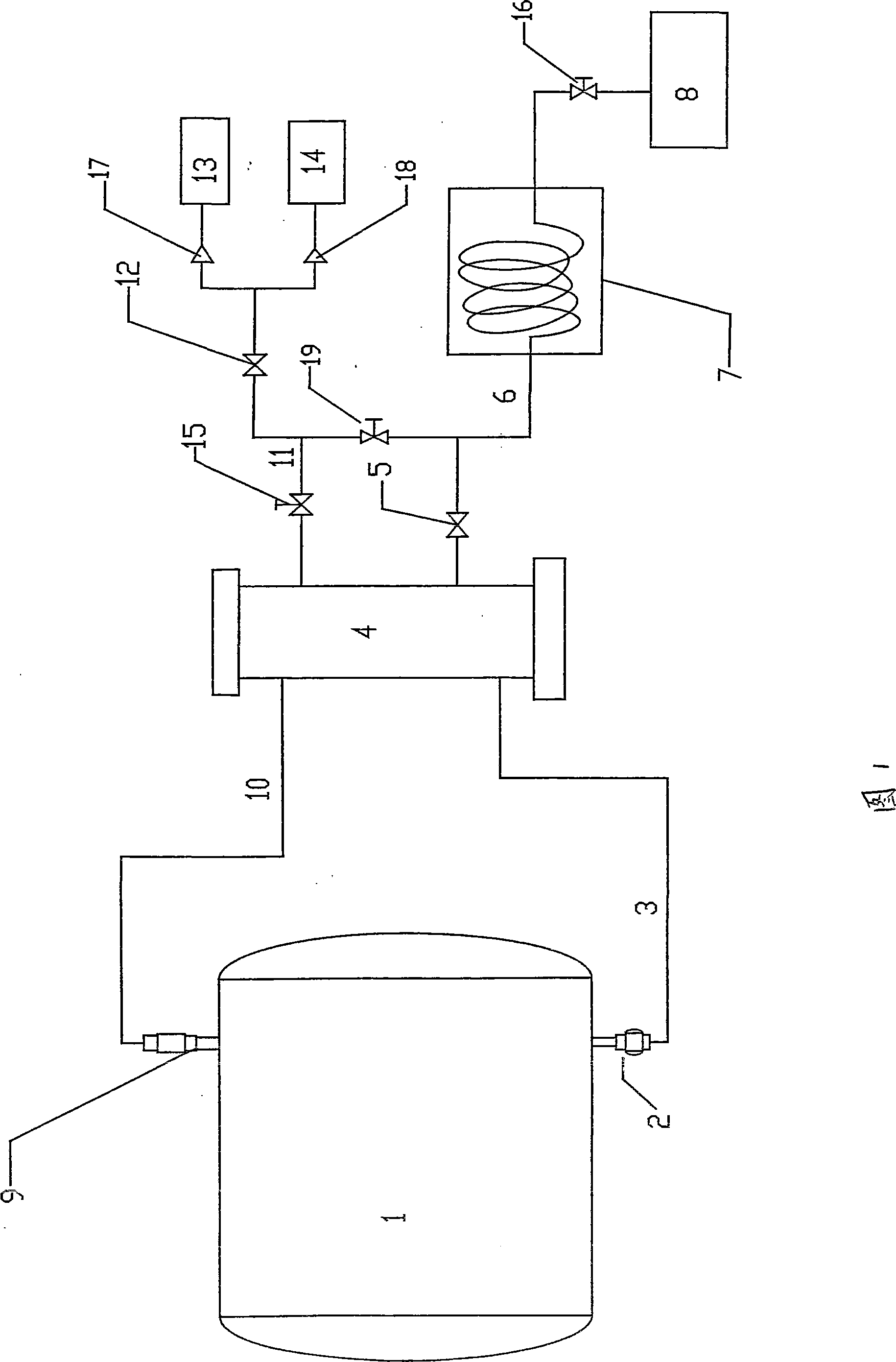

[0016] The high-temperature residual steam and high-temperature condensed water in the pressure steam kettle 1 are respectively passed through the residual steam output pipeline 10 and the high-temperature condensed water pipeline 3 into the pressure gas storage tank for flash evaporation, and the flashed steam is exhausted through the output pipeline 11 into the steam culture pool 13 or another pressure steam kettle 14 for reuse, so as to realize the recovery and utilization of waste heat and waste steam.

[0017] The steam after the flash is discharged into the steam culture tank 13 or another pressure steam kettle 14 and operated by one-way valves 17 and 18.

[0018] The condensed water after heat exchange in the pressure gas storage tank 4 is sent to the boiler feed water pool 7 through the pressure in the pressure gas storage tank, and heat exchange coils are installed in the water feed pool to heat the boiler feed water, and the condensed water after heat exchange is disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com