Geothermal paving plate

A pavement board and geothermal technology, applied in the field of construction, can solve the problems of restricting the progress of geothermal construction projects, unfavorable for the safety of buildings, and the large capacity of cement mortar carriers, so as to facilitate the pipe arrangement work, shorten the construction period, and reduce the overall weight. light effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] implementation benefit 1

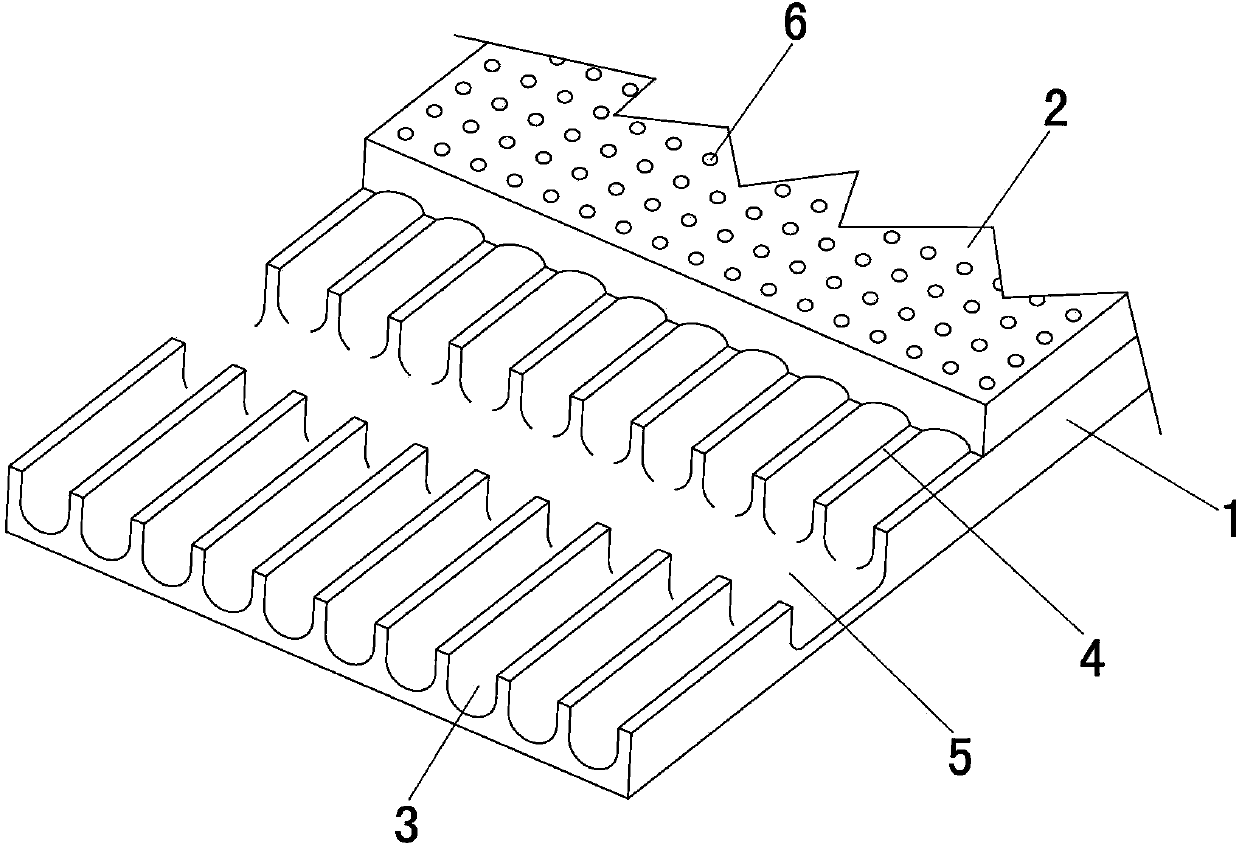

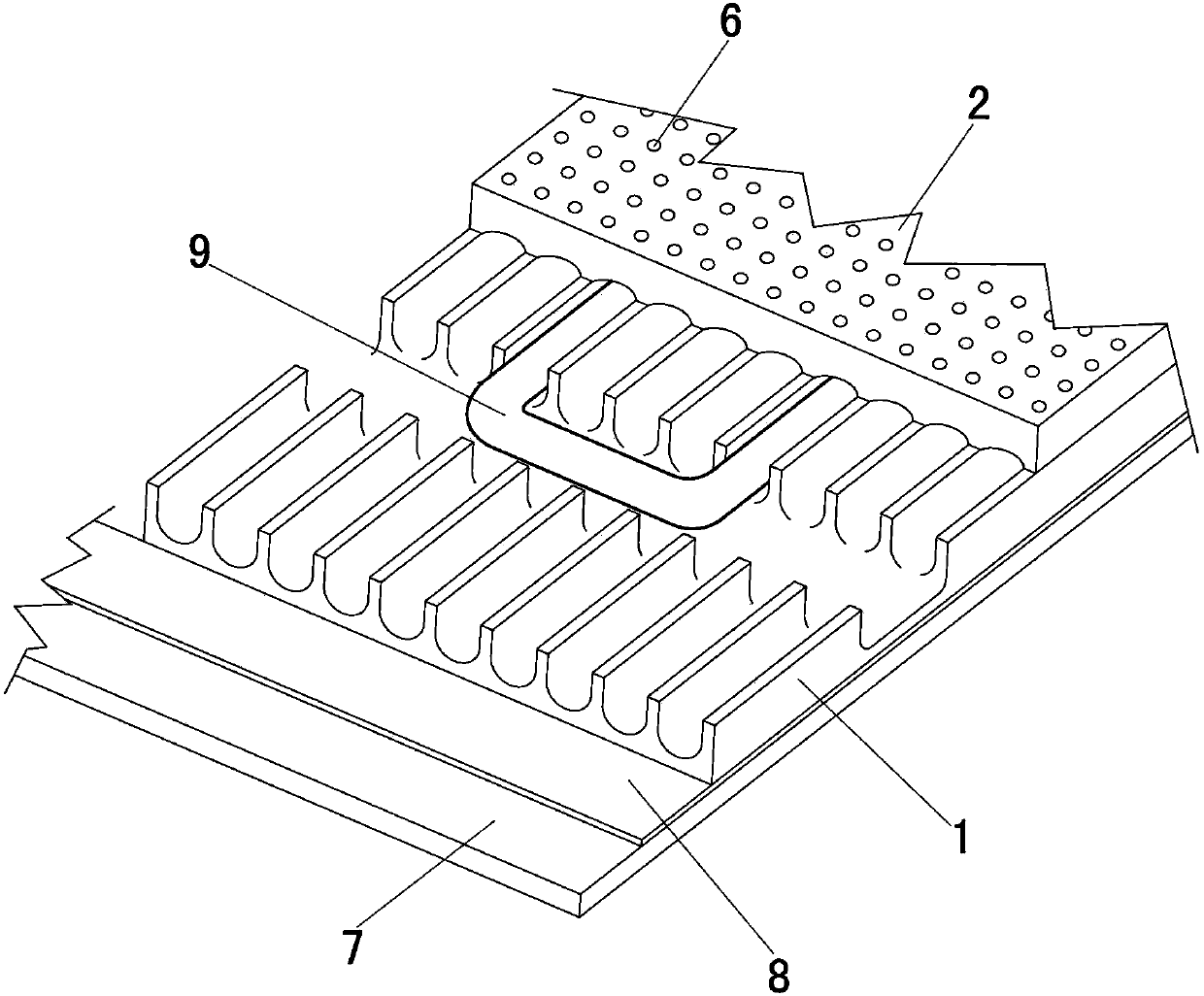

[0014] refer to figure 1 , figure 2 , a prefabricated lower pallet 1 made of sawdust cement and a flat upper cover 2, wherein the lower pallet has pipe row grooves 3 parallel in a straight line, and the groove walls 4 between the pipe grooves are distributed with heat pipes that can pass through the low heat pipes. The gap 5 and the through holes 6 are distributed on the upper cover plate 2 . Lay the heat insulation layer 7 on the rough floor, cover the waterproof layer 8 on the heat insulation layer 7, place the lower supporting plate 1 on the waterproof layer 8, lay the geothermal pipe 9 in the part of the lower supporting plate, and install the upper cover plate 2 Covering on the top of the lower supporting plate 1, the pavement of the geothermal pipe is completed.

[0015] implementation benefit 2

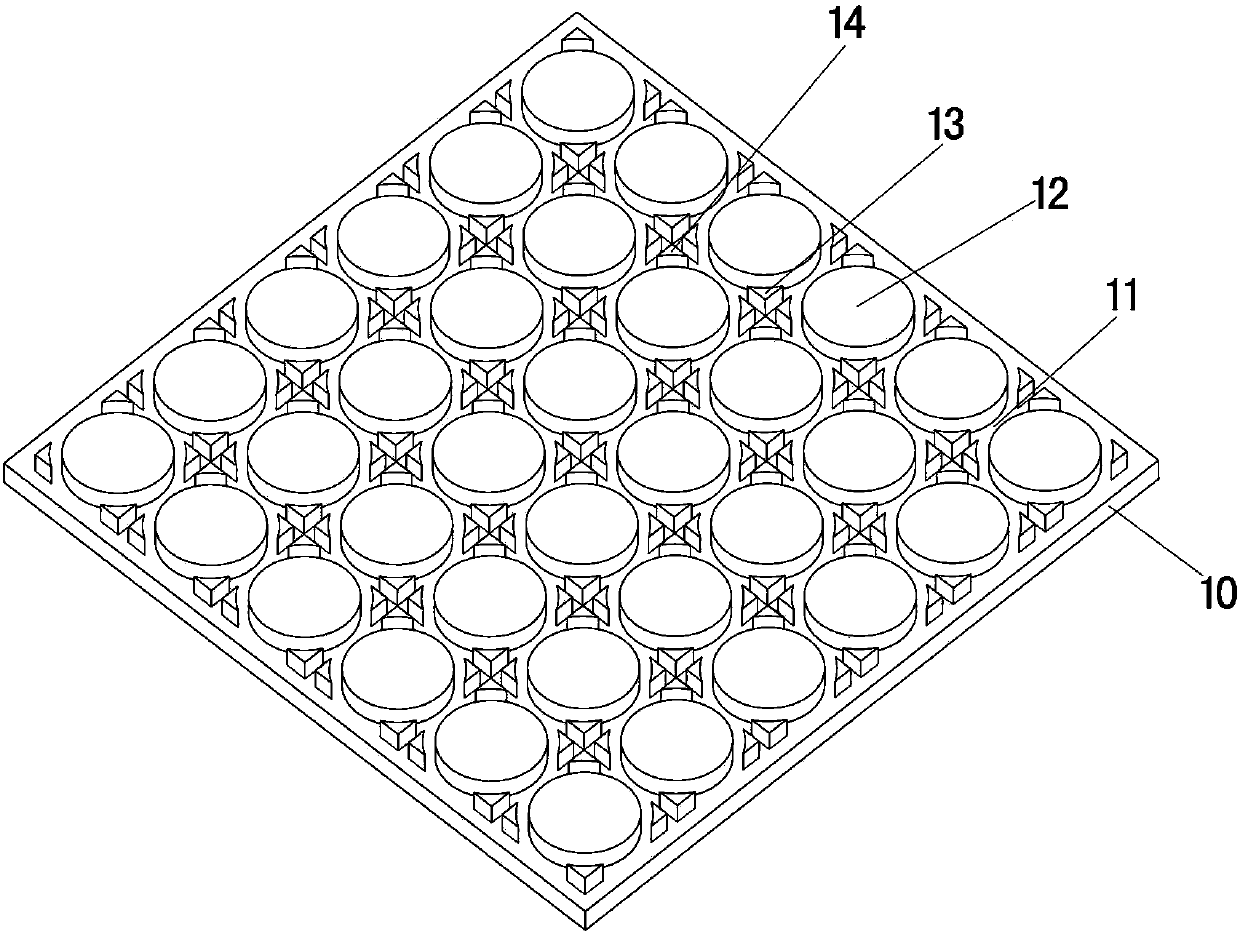

[0016] refer to image 3 , the lower supporting plate 10 of prefabricated foam cement material, the lower supporting plate 10 has vertic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com