Piezoelectric ceramic electro-acoustic conversion device

A technology of electro-acoustic transducers and piezoelectric ceramics, which is applied in the direction of piezoelectric/electrostrictive transducers, sensors, electrical components, etc., and can solve problems such as poor piezoelectric performance, difficulty in thinning, and non-compliance with thinning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

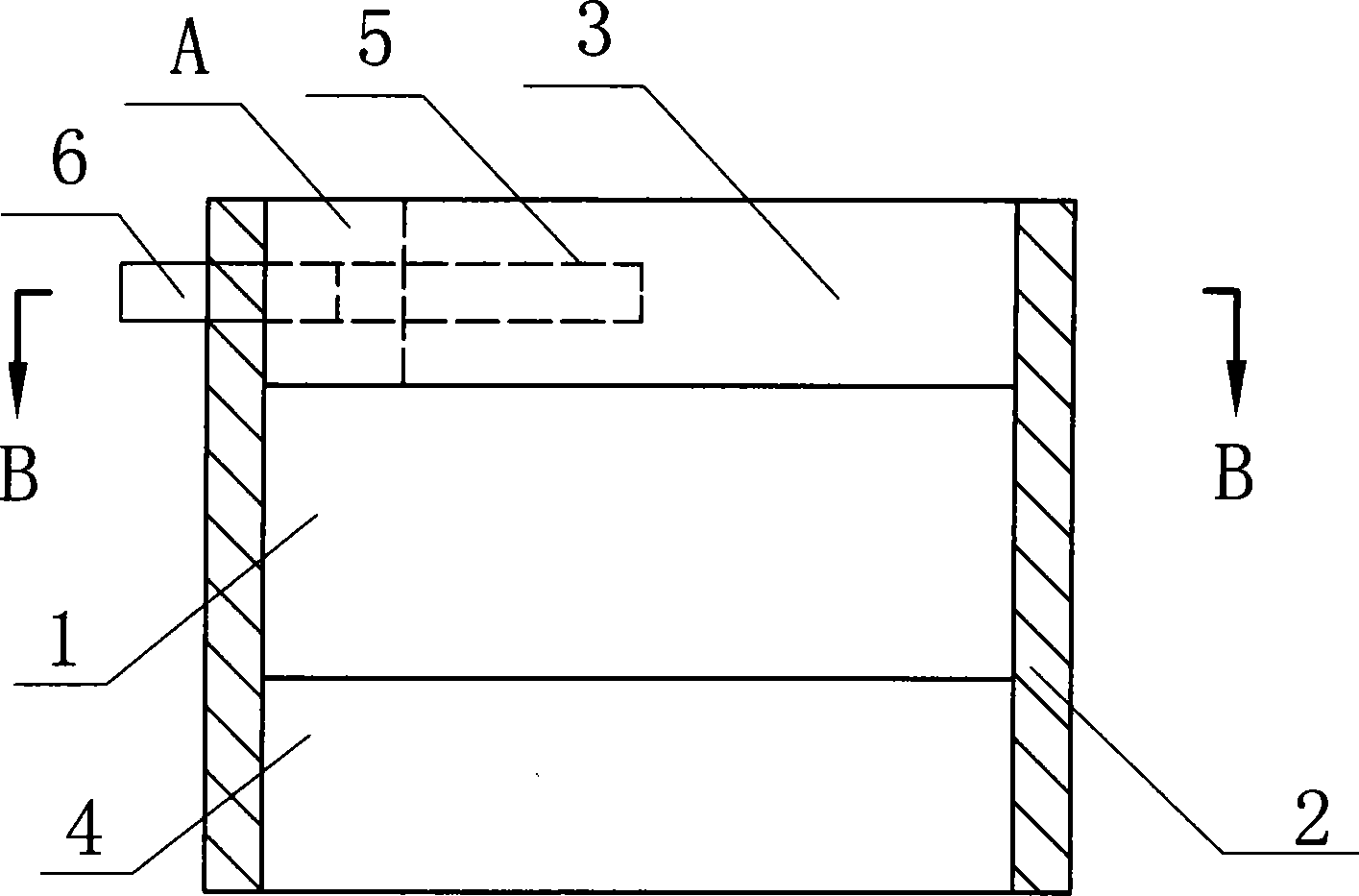

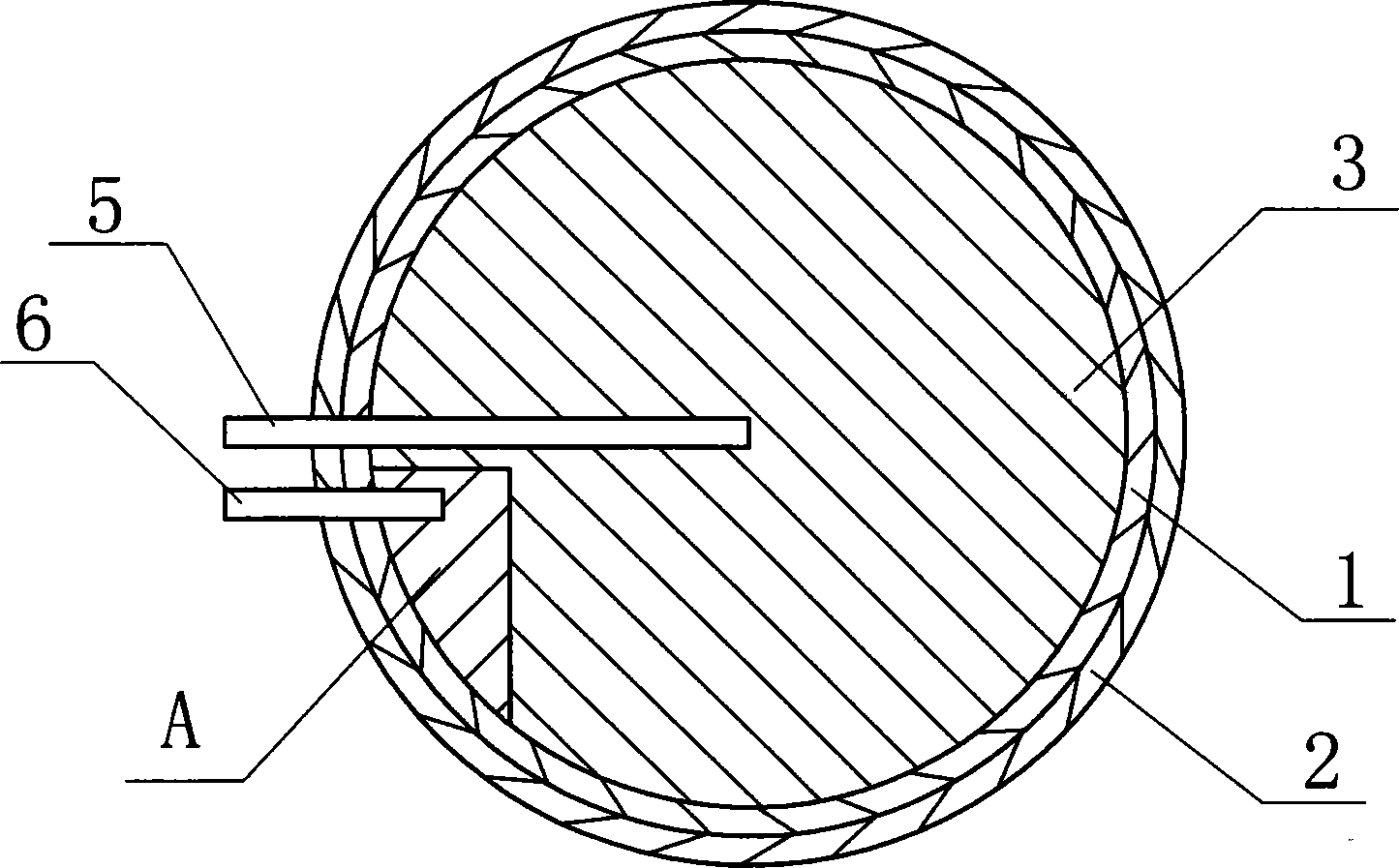

[0016] see figure 1 , a piezoelectric ceramic electroacoustic transducer, including a vibrating plate 1, a frame 2, a conductive path with electrodes 5, 6, and its innovative point is: it also includes a composite vibrating plate 1, piezoelectric ceramic membranes 3, 4 Diaphragm, the composite diaphragm is fixedly connected to the frame 2, the main surface of the vibration plate 1 is bonded with the piezoelectric ceramic film 3 to form one side of the composite diaphragm, and the other side of the vibration plate 1 is bonded with the pressure The electric ceramic film 4 constitutes the other side of the composite diaphragm, and the two electrodes 5 and 6 of the conductive path are respectively fixed on the same face of the composite diaphragm, that is, respectively fixed on the piezoelectric ceramic film 3 .

[0017] Depend on figure 1 and figure 2 It is shown that an area A is arranged on the piezoelectric ceramic film 3, and the electrode 6 is connected to the area A on t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com