Backlight module

A technology of a backlight module and a phosphor layer, applied in the field of light-emitting diode backlight modules, can solve the problems of unfavorable thin-shaped design of backlight modules, inconvenient heat dissipation, etc., and achieve the effect of reducing height and satisfying thinning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

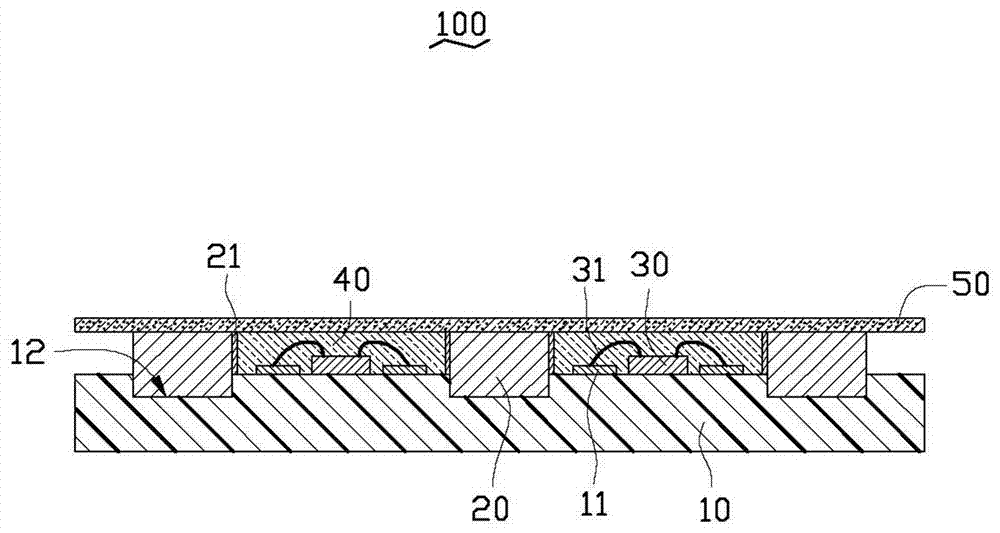

[0010] see figure 1 , the backlight module 100 of the present invention includes a circuit board 10, a plurality of hollow frames 20 fixed on the circuit board 10, light-emitting diode chips fixed on the circuit board 10 and housed in each frame 20 respectively 30. The colloid 40 filled in the frames 20 and wrapping the LED chip 30 and a phosphor layer 50 fixed on the top of the frames 20 .

[0011] The circuit board 10 is a long board with a flat top surface and a bottom surface parallel to the top surface. A circuit (not shown) and conductive contacts 11 electrically connected to the circuit are formed on the top surface. The conductive contacts 11 protrude from the top surface and are arranged at intervals. Each LED has two metal wires 31 . The LED chips 30 are mounted on the top surface of the circuit board 10 and the two metal wires 31 are electrically connected to the two conductive contacts 11 respectively. The height of the conductive contacts 11 protruding upward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com