Method for manufacturing thin membrane silicon electrooptical device with single-chamber plasma case

A plasma box and photoelectric conversion technology, which is applied in the manufacture of electrical components, semiconductor devices, semiconductor/solid-state devices, etc., can solve the problems of non-interchangeable use, limitation and productivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

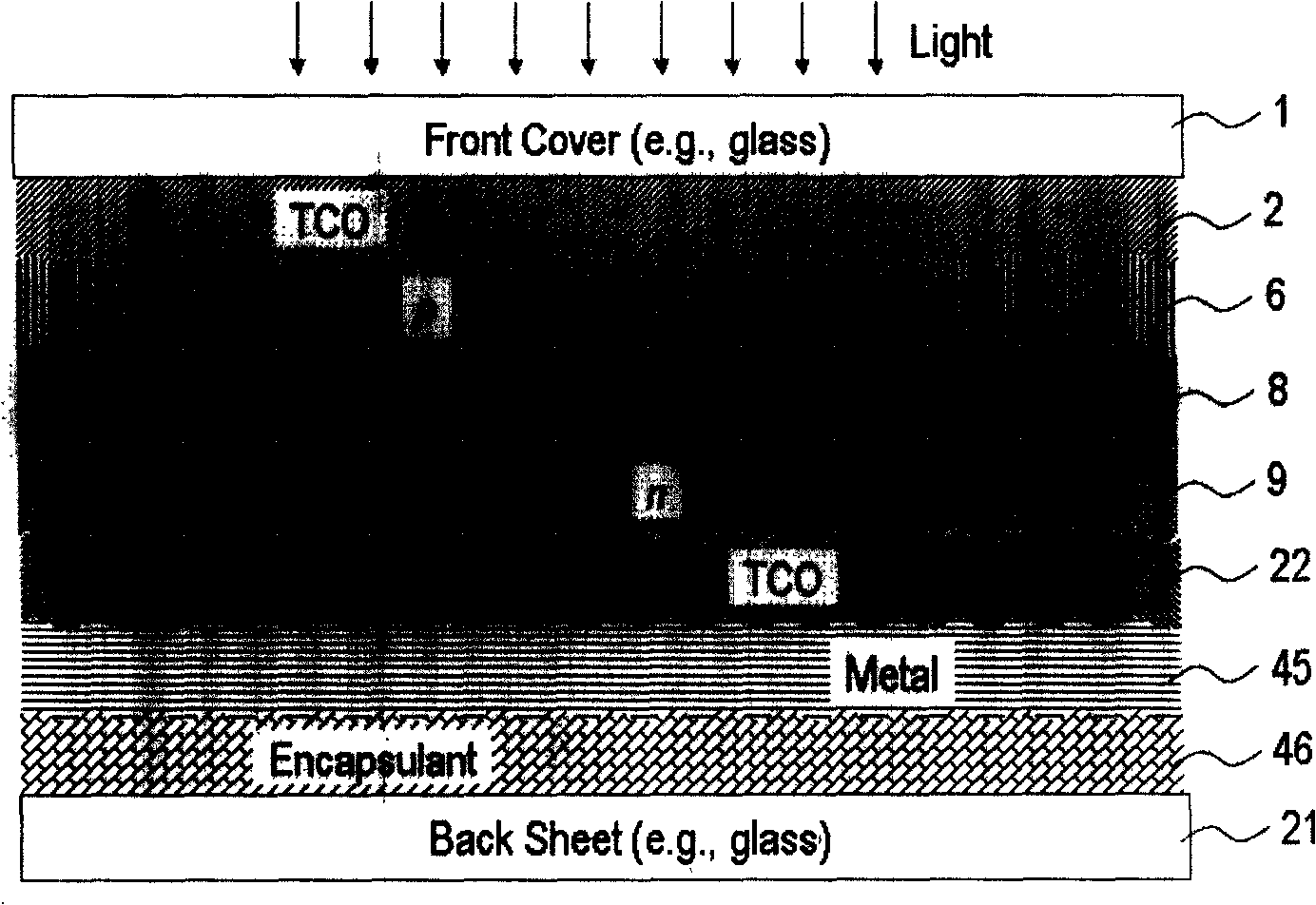

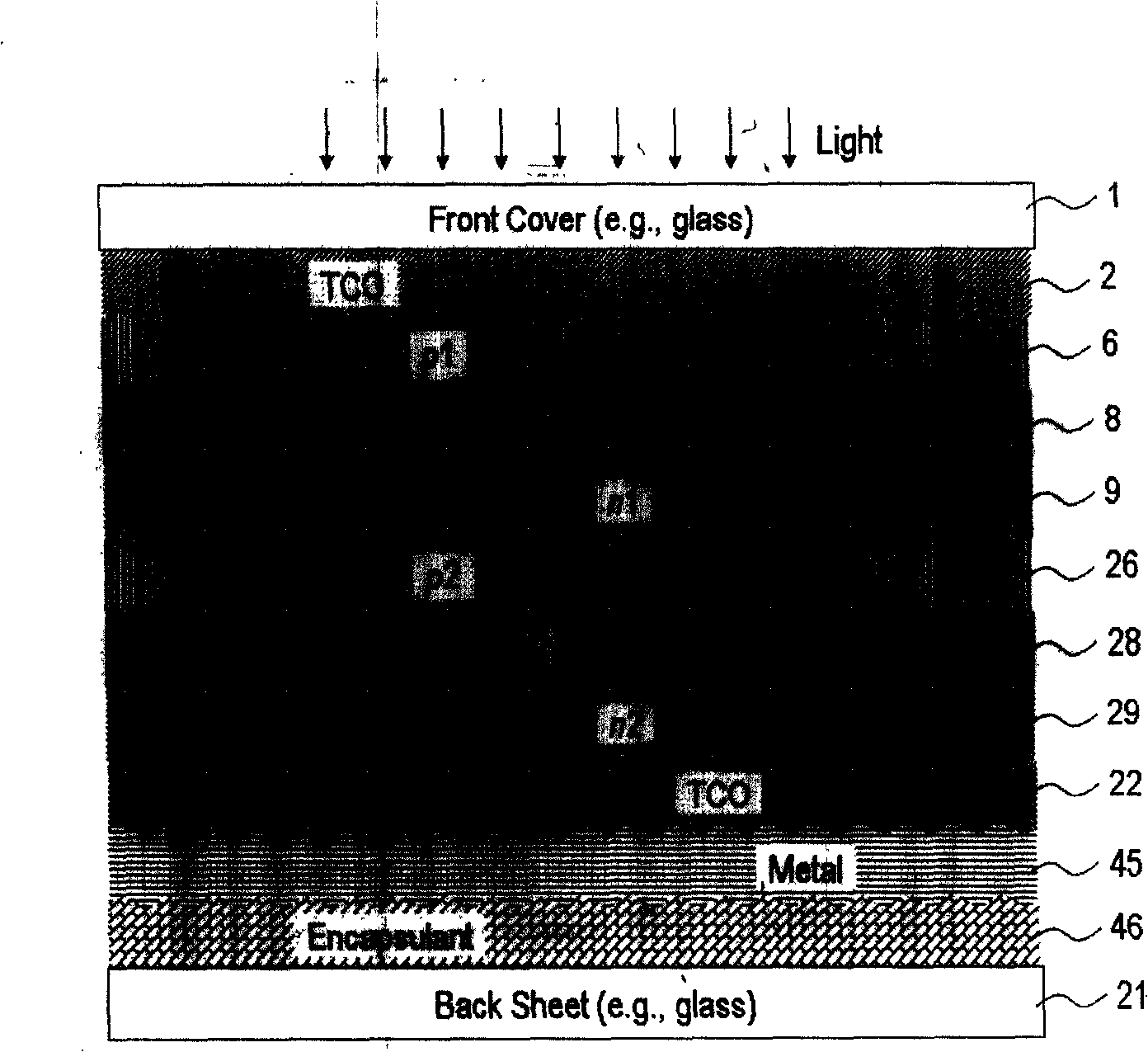

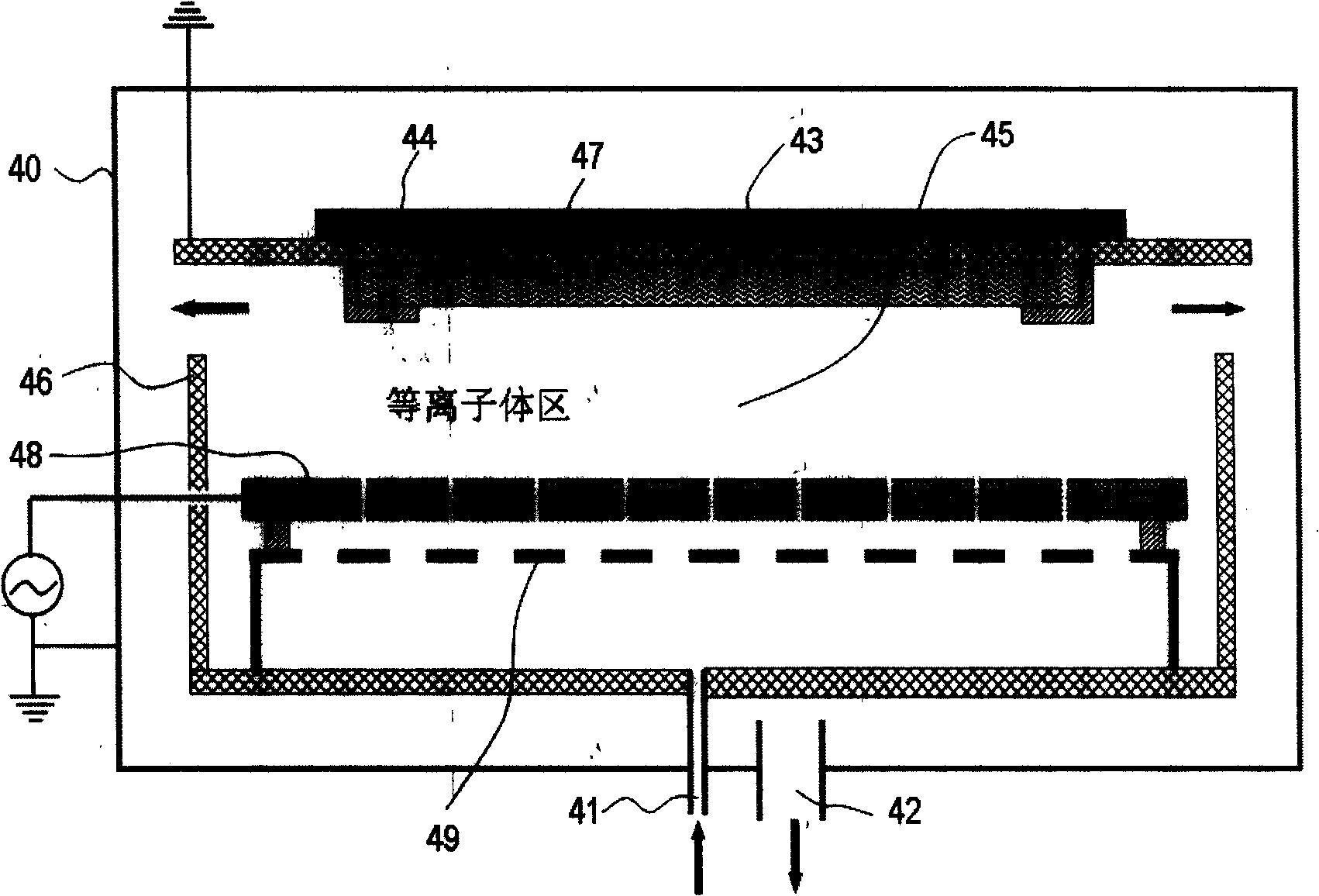

[0032] process Figure 5 shows a typical production procedure for employing Figure 4 The PECVD system shown fabricates a stacked double-junction thin-film silicon p-i-n photoelectric device (eg figure 2 shown). This production step is described below as an application example of the present invention. In the first step S1, the glass substrate 3 coated with the tin oxide front electrode is put into the plasma box 20 fixedly placed in the single vacuum chamber 10 which is preheated to a temperature higher than 200°C. In the second step S2, the vacuum chamber is evacuated by a dry pump to make the air pressure lower than 8×10 -6 mbar. At the same time, the heating power of the vacuum chamber 10 is adjusted so that the temperature inside the vacuum chamber (including the temperature inside the plasma box 20 ) is stably maintained at a predetermined value between 160°C and 260°C. A number of temperature sensors are placed at various points inside the vacuum chamber 10, inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com