Integrated circuit encapsulation structure for improving glue padding

An integrated circuit and filling technology, applied in the direction of circuits, electrical components, electrical solid devices, etc., can solve the problems of general products without structure, air bubbles 131 attached, and air covered, so as to facilitate the thinning of packaging and reduce the Air bubbles and crevices are formed to increase fluidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

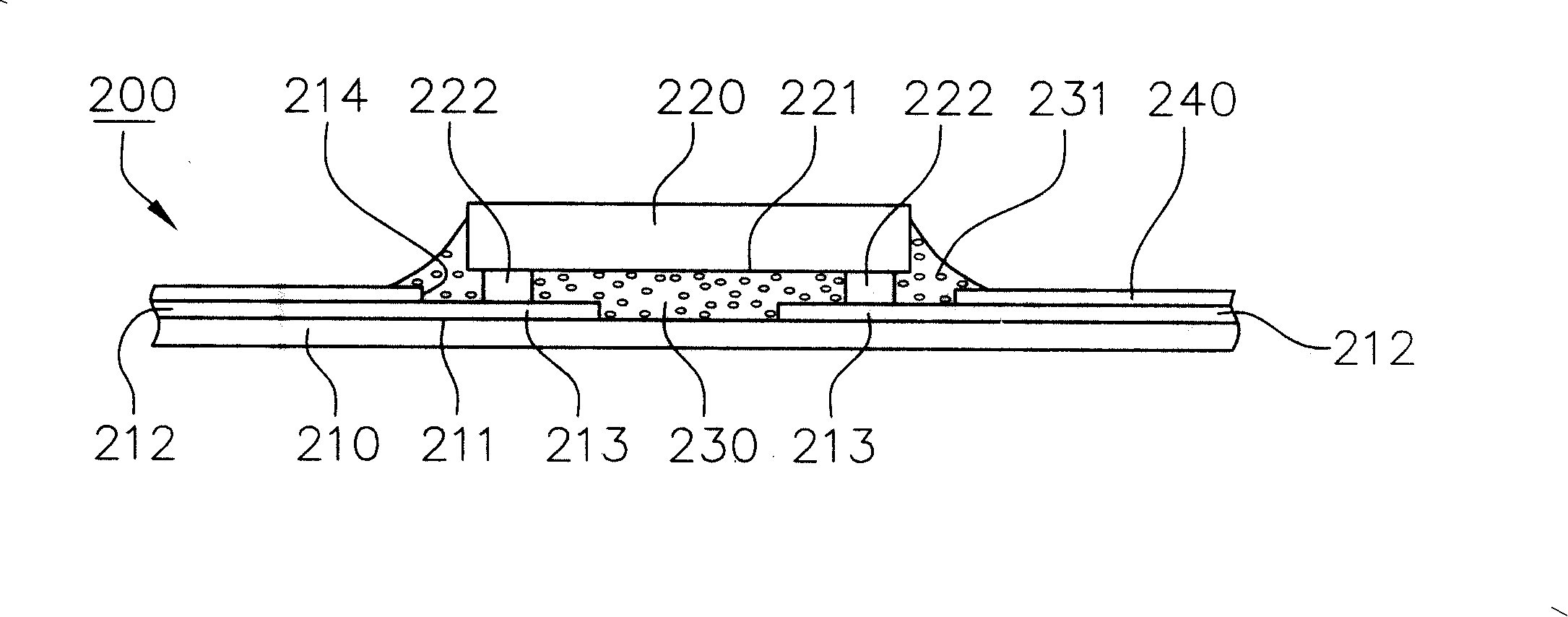

[0041] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, the specific implementation and structure of the integrated circuit packaging structure for improving the filling property of the present invention are presented. , features and their effects are described in detail below.

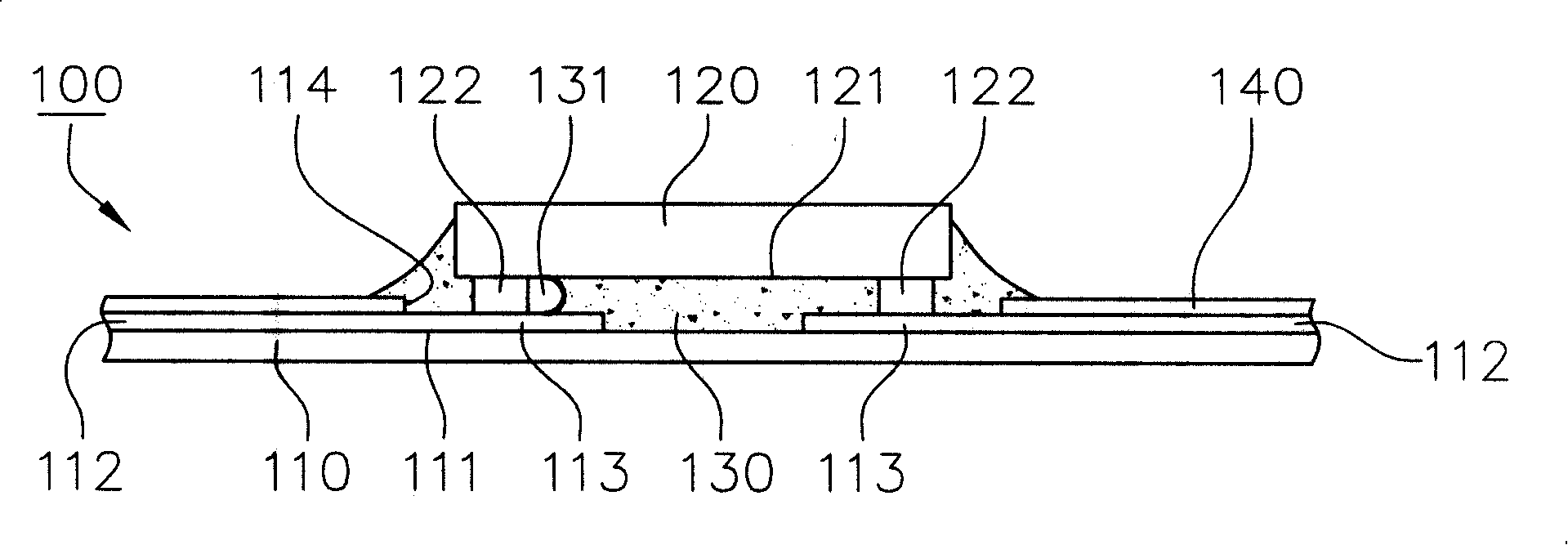

[0042] see image 3Shown is a schematic cross-sectional view of an integrated circuit package structure for improving the filling property according to a specific embodiment of the present invention. A specific embodiment of the present invention discloses an integrated circuit packaging structure that improves the filling property of the glue. The integrated circuit packaging structure 200 mainly includes a substrate 210 , a chip 220 and a highly filling liquid packaging resin 230 .

[0043] The substrate 210 has an upper surface 211 , ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com