Semiconductor encapsulation structure for improving wafer shift upon pressing

A semiconductor and chip technology, applied in the field of lead frame, to protect the chip and improve the effect of vertical position deviation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment

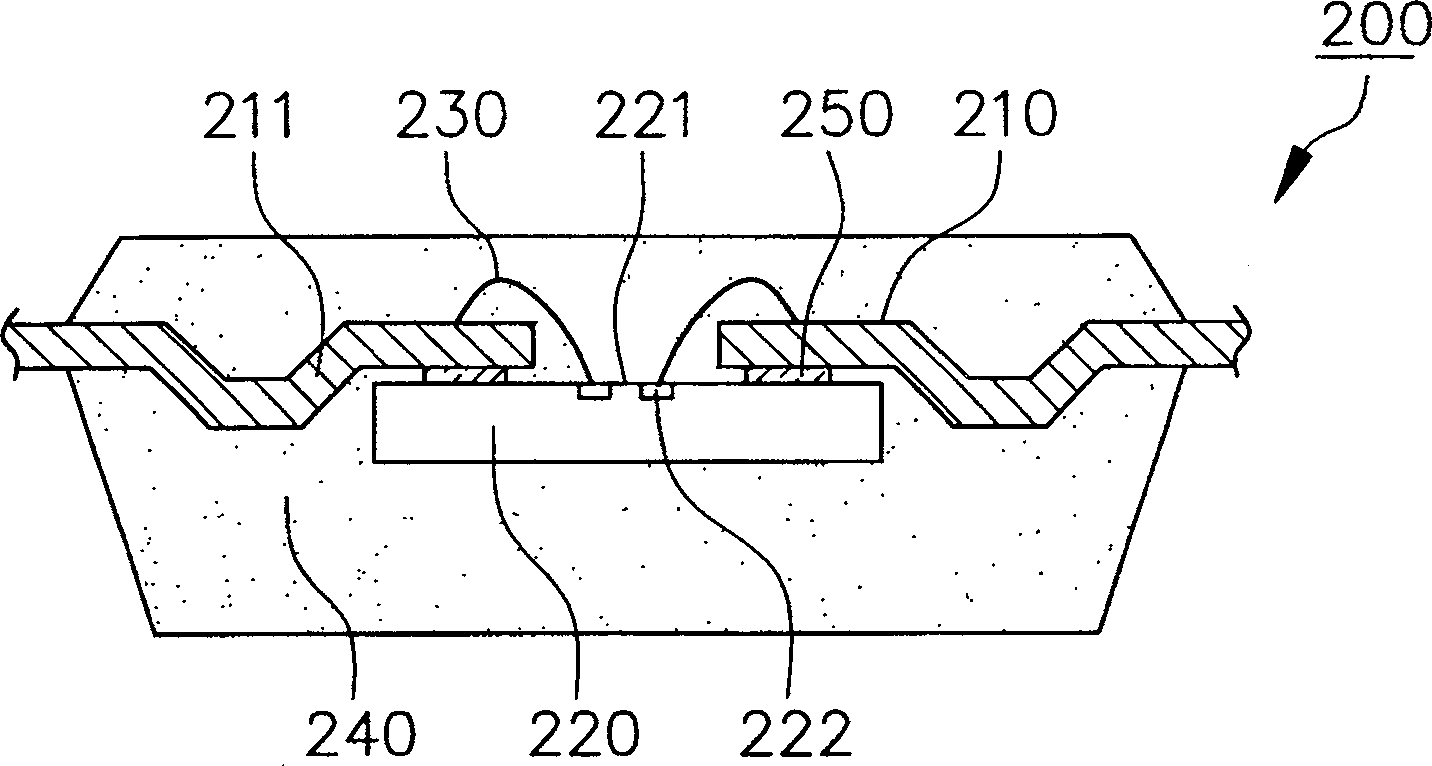

[0074] Please refer to FIG. 5, according to the first embodiment of the present invention, the lead frame further includes at least one spoiler 316, which is located at the mold flow injection port and the discharge port (not shown in the figure), the spoiler The flow plate 316 can prevent the molding compound 340 from producing uneven mold flow.

[0075] The lead frame defines a molding area 317 and a die-bonding area 318 within the molding area 317. The molding area 317 is used as the forming position of the encapsulant 340. The size and position of the die-bonding area 318 is the corresponding size and position of the active surface 321 of the chip 320 . In this embodiment, as shown in FIG. 5 , the second horizontal pin portions 313 can extend from the two short sides of the die-bonding region 318 (ie, the active surface 321 ) to the die-bonding region 318 to shorten the length of the die-bonding region 318. The length of the electrical connection element 330 reaches the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com