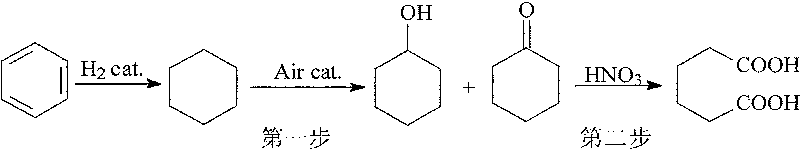

Method for preparing adipic acid by using cyclohexane catalytic oxidation one-step method

A catalytic oxidation, cyclohexane technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylates, etc., can solve problems such as high price and unsuitability for industrial applications, avoid the use of nitric acid, and reduce deep oxidation. Product formation, effect of suppressing a series of side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Add 237g of cyclohexane, acetone, tert-butyl hydroperoxide and solid catalyst into a closed reaction kettle and mix to form a mixed suspension. Wherein, the weight ratio of acetone and cyclohexane is 1:1.5, and cyclohexane is loaded with RuO 2 The weight ratio of the solid catalyst is 474:1, and the catalyst is RuO supported by carbon nanotube carrier. 2 , the publication number proposed by the applicant is prepared by the preparation example 1 method described in the CN1806914A patent application, and its solid carrier and RuO 2 The weight ratio is 90:10. The weight ratio of cyclohexane to t-butyl hydroperoxide was 34:1. The mixed suspension is heated to 125°C under stirring, and oxygen is introduced to 1.5Mpa. Since the reaction process continuously consumes oxygen in a stoichiometric ratio, it is continuously replenished through a pressure stabilizing device and a flow meter connected to an oxygen source during the reaction. Oxygen and keep the pressure constant a...

Embodiment 2~4

[0053] Add 237g of cyclohexane, acetone, cyclohexanone and solid catalyst into a closed batch reactor and mix to form a mixed suspension. Wherein, the weight ratio of acetone and cyclohexane is 1:1.5, and cyclohexane is loaded with RuO 2 The weight ratio of the solid catalyst is 474:1, and the catalyst is RuO supported by carbon nanotube carrier. 2 , the publication number proposed by the applicant is prepared by the preparation example 1 method described in the CN1806914A patent application, and its solid carrier and RuO 2 The weight ratio is 90:10. The weight ratio of cyclohexane to cyclohexanone is 40:1. The mixed suspension is heated to the temperature shown in Table 2 respectively under stirring, and oxygen is introduced to 1.5Mpa. Since the reaction process consumes oxygen in a stoichiometric ratio, the pressure stabilizing device connected to the oxygen source is passed through during the reaction. And the flow meter constantly replenishes oxygen and keeps the pressu...

Embodiment 5

[0058] Add 237g of cyclohexane and the corresponding amount of acetone, cyclohexanone and solid catalyst into a closed batch reactor and mix to form a mixed suspension. Wherein, the weight ratio of solvent and cyclohexane is 1: 1.5, the weight ratio of cyclohexane and catalyst is 474: 1, the weight ratio of cyclohexane and cyclohexanone is 40: 1, and the catalyst is supported by carbon nanotube carrier RuO 2 , the publication number proposed by the applicant is prepared by the preparation example 1 method described in the CN1806914A patent application, and its solid carrier and RuO 2 The weight ratio is 90:10. This mixed suspension is heated to 125 ℃ under agitation, feeds oxygen to 1MPa, reacts for 8 hours, the separation and analysis method of product is the same as embodiment 1~4, and cyclohexane conversion rate is 24%, and adipic acid selectivity is 38%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com