Ultra-low carbon hot rolling weather-resisting steel with yield strength more than 450MPa

A yield strength, ultra-low carbon technology, applied in the field of low-alloy steel manufacturing, can solve the problems of poor mechanical properties, poor atmospheric corrosion resistance, and high C content, and achieve the effects of excellent mechanical properties, simple chemical composition, and improved corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

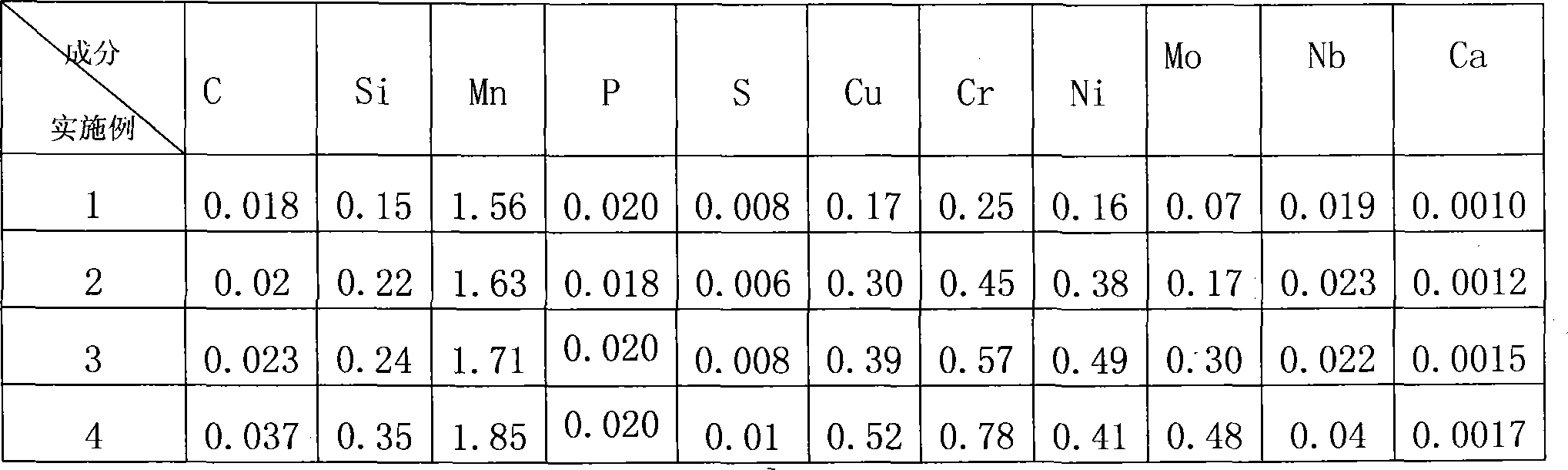

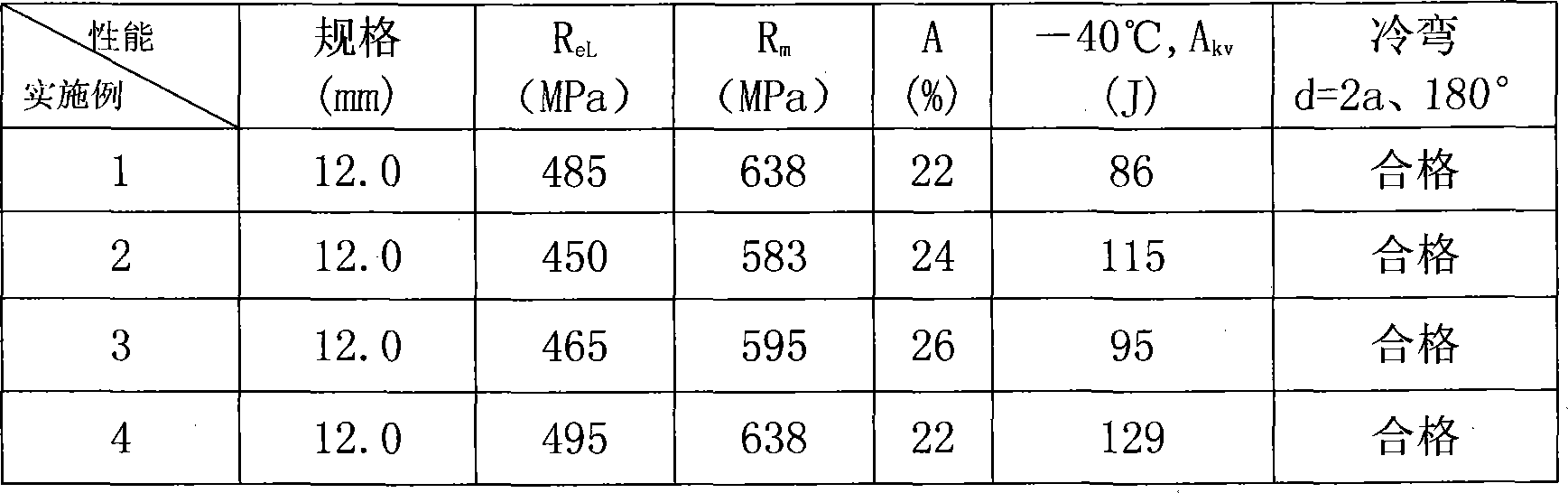

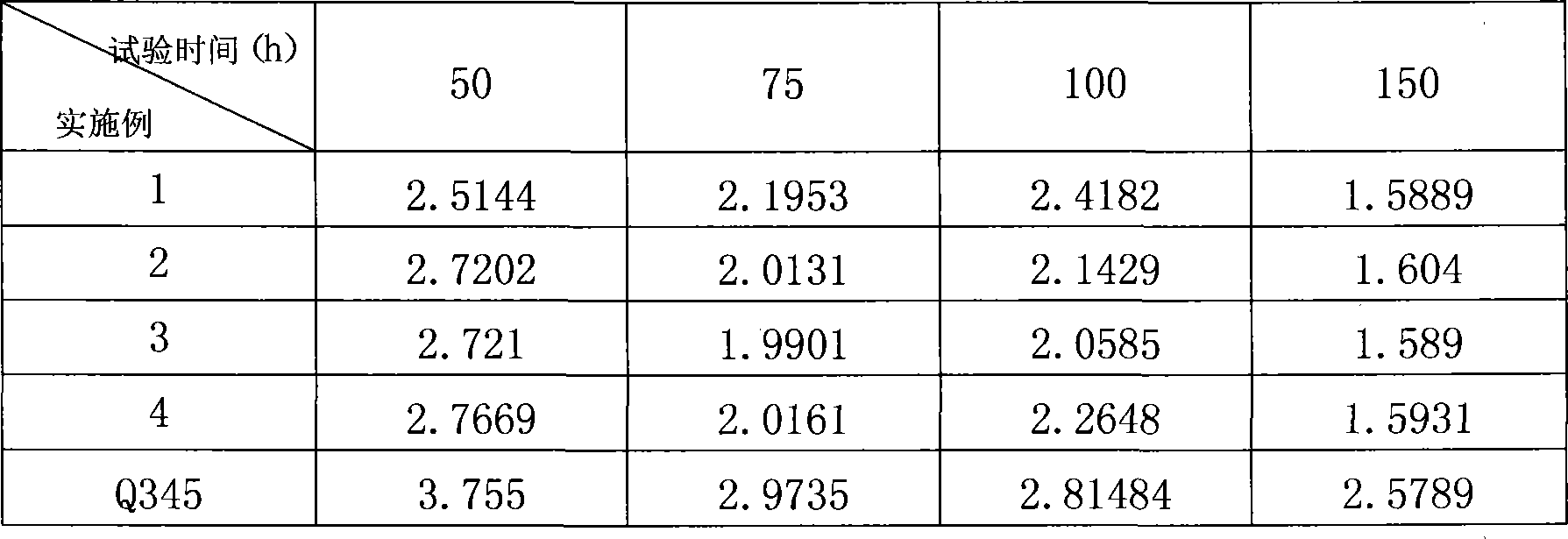

[0030] According to the above production process, steel 1 was produced, wherein the chemical composition of steel 1 is shown in 1 in Table 1, the mechanical properties of steel 1 are shown in 1 in Table 2, and the atmospheric corrosion resistance results of steel 1 are shown in 1 in Table 3.

Embodiment 2

[0032] According to the above production process, steel 2 is produced, wherein the chemical composition of steel 2 is shown in 2 in Table 1, the mechanical properties of steel 2 are shown in 2 in Table 2, and the atmospheric corrosion resistance results of steel 2 are shown in 2 in Table 3.

Embodiment 3

[0034] According to the above production process, steel 3 is produced, wherein the chemical composition of steel 3 is shown in 3 in Table 1, the mechanical properties of steel 3 are shown in 3 in Table 2, and the atmospheric corrosion resistance results of steel 3 are shown in 3 in Table 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com