Technique for extracting residual acetylene gas in acetylene generator (wet method) carbide slag slurry

An acetylene generator and calcium carbide slurry technology are applied in the parts of acetylene gas generators, acetylene generators, petroleum industry and other directions, which can solve the problems of environmental pollution and waste of raw material acetylene gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

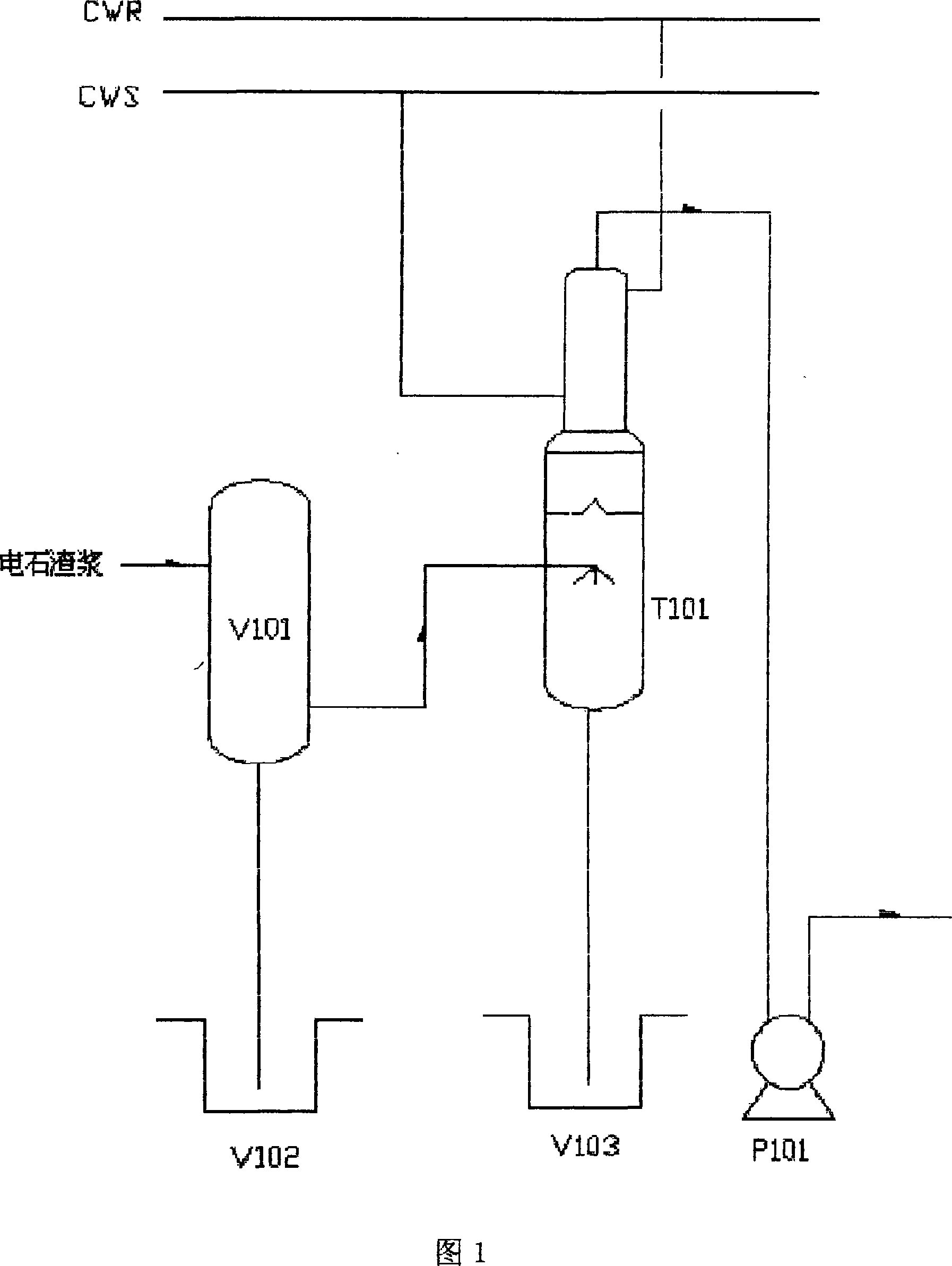

[0013] 1. Collect all the carbide slag slurry discharged from the acetylene generator into the buffer tank (V101), and then send it to the desorption tower (T101). The slurry settled at the bottom of the buffer tank is regularly discharged into the settling tank. Under the action of the vacuum pump (P101), the desorption tower (T101) maintains a negative pressure of -0.06~-0.08MPa, and the residual acetylene gas in the carbide slag slurry is decomposed by boiling, and at the same time, the solid Ca(OH) 2 The adsorbed acetylene gas is also separated out, and the water vapor and acetylene gas are separated at the top of the stripping tower (T101). The separated calcium carbide slag slurry flows into the concentration tank (V103) from the sewage outlet at the bottom of the separation tower (T101). The purity of the separated acetylene gas can reach more than 95%, which can be directly incorporated into the acetylene system. The invention adopts a combined desorption tower, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com