Green synthesis method for ketazine

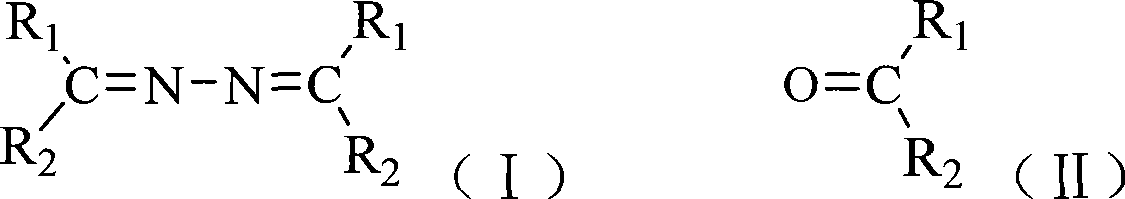

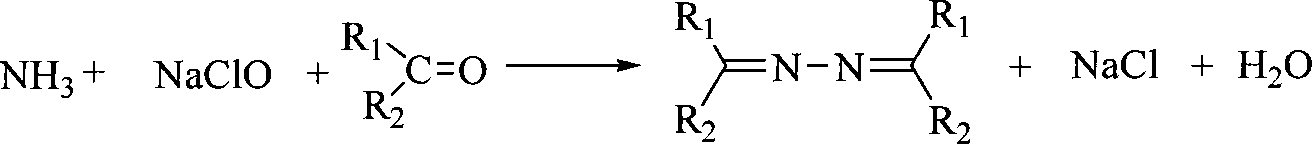

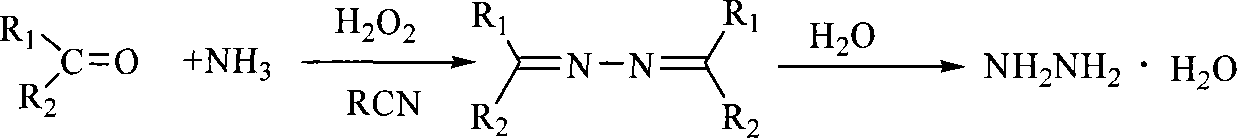

A green synthesis and ketazine technology, which is applied in the preparation of hydrazones and organic chemistry, can solve the problems of increased production costs, achieve good thermal stability, and be easy to recycle and recycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] Acetamide (5.9g, 0.1mol), sodium hexametaphosphate (0.3g, 0.0005mol), acetonitrile (10.5mL, 0.20mol), polyethylene glycol were added successively into a 100mL three-necked round-bottomed flask equipped with a thermometer and a condenser. Alcohol 6000 (1g, 0.0002mol), methyl ethyl ketone (36mL, 0.40mol), add dropwise 25% (w / w) ammonia water (18.0mL, 0.20mol), 30% (w / w) hydrogen peroxide (10.22mL , 0.10mol), stirred at 40°C for 8 hours, separated with a separatory funnel, separated the organic layer, and distilled to obtain 10.03 grams of methyl ethyl ketazine (I-1), with a yield (calculated as hydrogen peroxide) of 71.7%.

[0047]

Embodiment 2

[0049] Acetamide (5.9g, 0.1mol), sodium hexametaphosphate (0.3g, 0.0005mol), acetonitrile (10.5mL, 0.20mol), polyethylene glycol were added successively into a 100mL three-necked round-bottomed flask equipped with a thermometer and a condenser. Alcohol 6000 (1g, 0.0002mol), acetone (29.5mL, 0.40mol), add dropwise 25% (w / w) ammonia water (18.0mL, 0.20mol), 30% (w / w) hydrogen peroxide (10.22mL , 0.10mol), stirred at 40°C for 8 hours, added solid sodium hydroxide in an ice-water bath until saturated, kept the temperature not exceeding 30°C during the period, left the solution to separate layers, separated with a separatory funnel, separated the organic layer, and distilled 8.46 g of acetonazine (I-2) was obtained, and the yield (calculated as hydrogen peroxide) was 75.6%.

[0050]

Embodiment 3

[0052] Acetamide (5.9g, 0.1mol), sodium hexametaphosphate (0.3g, 0.0005mol), acetonitrile (10.5mL, 0.20mol), polyethylene glycol were added successively into a 100mL three-necked round-bottomed flask equipped with a thermometer and a condenser. Alcohol 400 (1g, 0.0025mol), methyl ethyl ketone (36mL, 0.40mol), add dropwise 25% (w / w) ammonia water (18.0mL, 0.20mol), 30% (w / w) hydrogen peroxide (10.22mL , 0.10mol), stirred at 70°C for 5 hours, separated with a separatory funnel, separated the organic layer, and distilled to obtain 11.28 grams of methyl ethyl ketazine, with a yield (calculated as hydrogen peroxide) of 80.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com