Cement-base material microorganism tectorial membrane protection agent, preparing method and application thereof

A cement-based material and protective agent technology, applied in the biological field, can solve the problems of cement-based material surface performance degradation, easy loosening and peeling of the surface, acceleration of concrete durability, etc., to achieve excellent performance, significant protective effect of coating, good The effect of weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

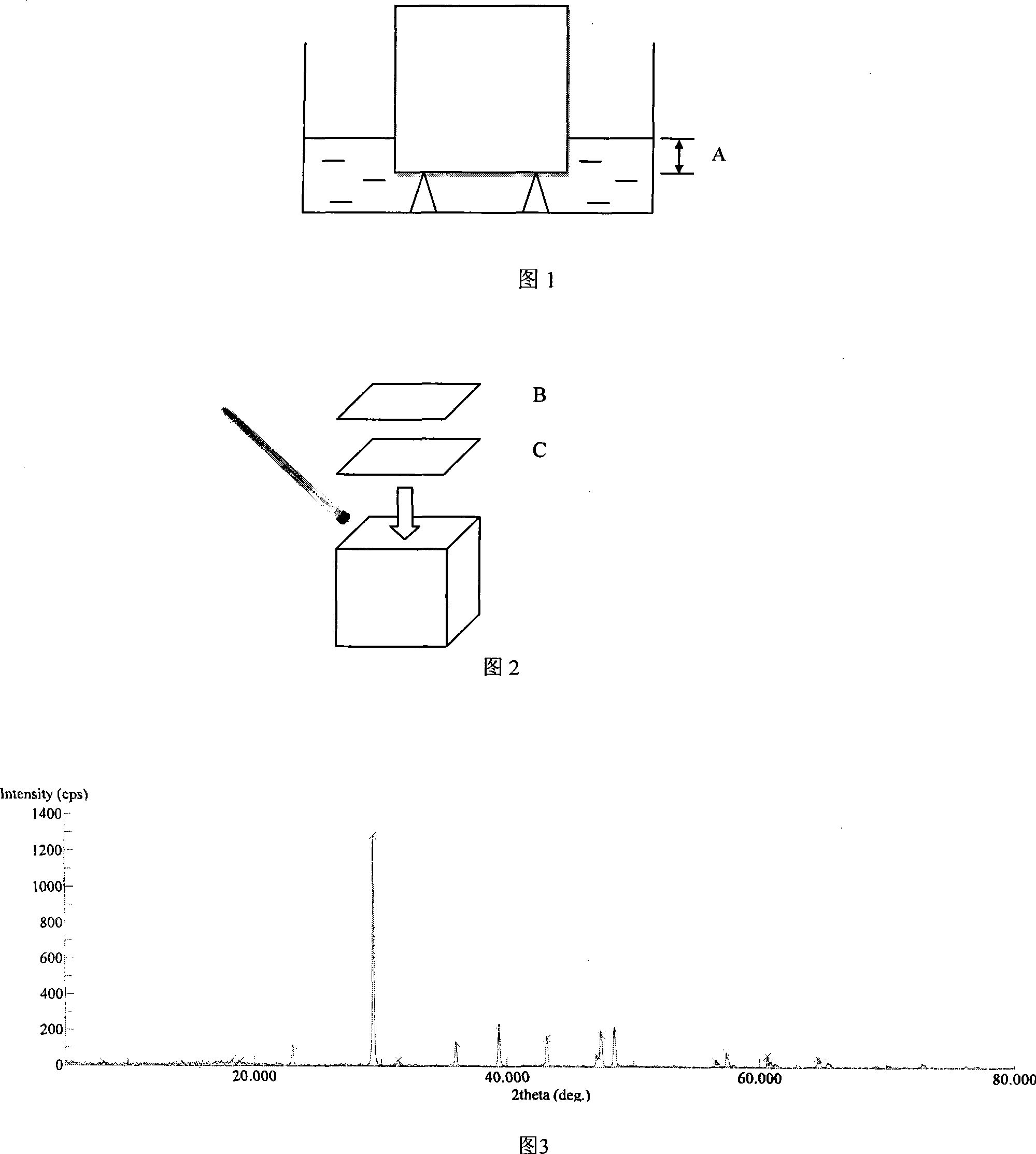

Method used

Image

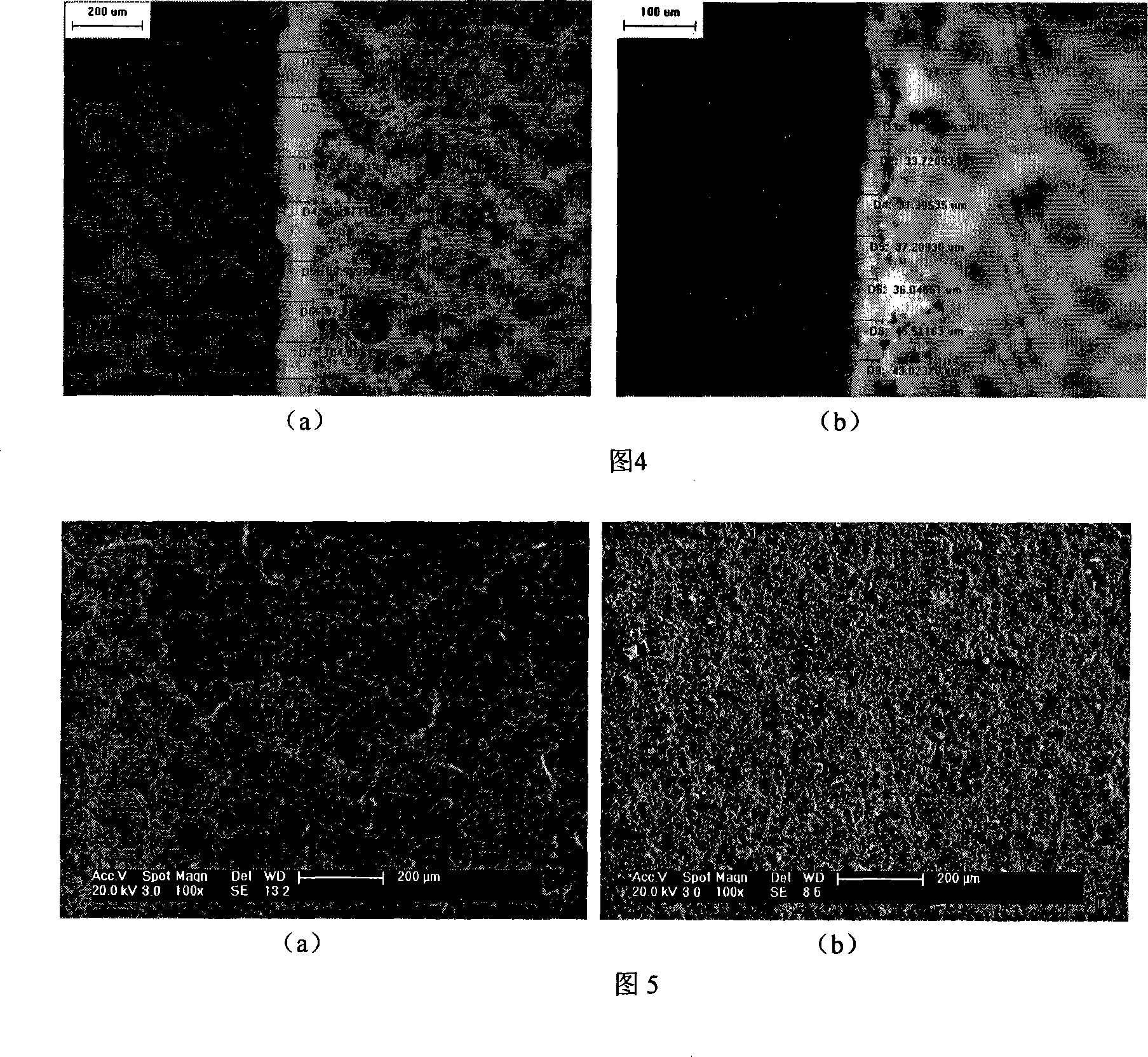

Examples

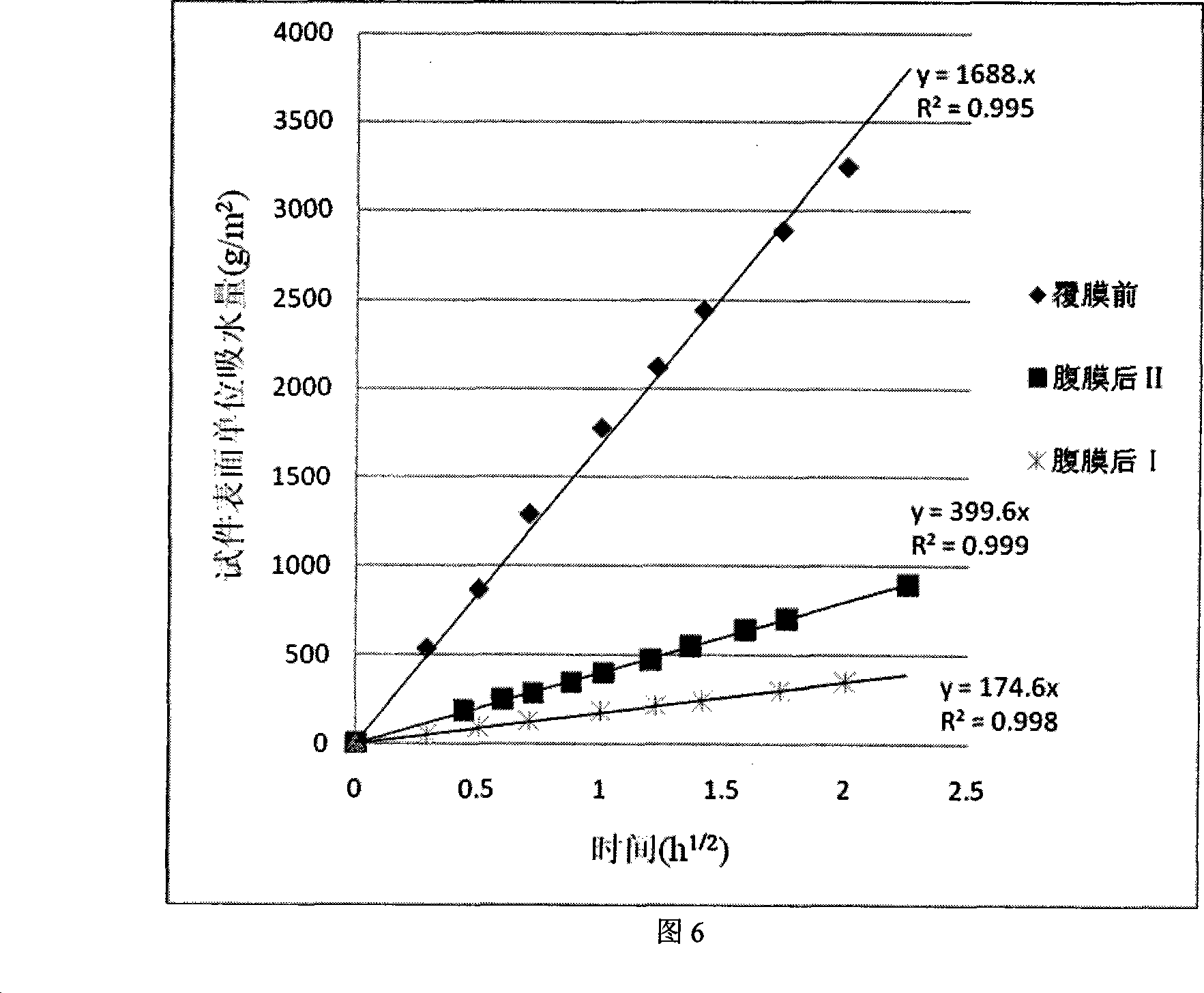

Embodiment 1

[0027] Inoculate the strain Bacillus pasteurii into the culture solution containing the urea-containing substrate. The composition is shown in Table 1. Shake culture at 25-37°C, take it out after 16-24 hours, and centrifuge at 5000-8000rpm 5-8 minutes, remove the supernatant, collect the cells of the strain with the culture medium, measure the OD value of the transmittance of the concentrated bacterial liquid with a UV-visible light spectrophotometer, and divide the collected strain cells according to the linear calibration curve between the OD value and the concentration of the bacterial liquid Concentration control is 4×10 10 cell / mL. Then prepare urea and Ca(NO 3 ) 2 Mixed solution, the concentration is 5mol / L, add 2g agar powder per liter of mixed solution, mix and heat to 90°C, after the agar is completely dissolved, put it at room temperature and cool to 50°C, then mix with the concentrated bacterial solution collected by centrifugation according to 1 Stir and mix at ...

Embodiment 2

[0029] Inoculate the strain Bacillus pasteurii into the culture solution containing the urea-containing substrate. The composition is shown in Table 1. Shake culture at 25-37°C, take it out after 16-24 hours, and centrifuge at 5000-8000rpm 5-8 minutes, remove the supernatant, collect the cells of the strain with the culture medium, measure the OD value of the transmittance of the concentrated bacterial liquid with a UV-visible light spectrophotometer, and divide the collected strain cells according to the linear calibration curve between the OD value and the concentration of the bacterial liquid Concentration control is 4×10 9 cell / mL. Then prepare urea and Ca(NO 3 ) 2 Mixed solution, the concentration is 5mol / L, add 2g agar powder per liter of mixed solution, mix and heat to 90°C, after the agar is completely dissolved, put it at room temperature and cool to 50°C, then mix with the concentrated bacterial solution collected by centrifugation according to 1 Stir and mix at a...

Embodiment 3

[0031] A protective agent for microbial coating of cement-based materials. The protective agent is composed of microbial bacterial liquid capable of synthesizing minerals and a coagulant, wherein the volume ratio of the microbial bacterial liquid and the coagulant is 1:1. The microbial bacterial liquid is Bacillus pasteurii, and the bacterial liquid concentration is 4×10 9 cell / mL. The coagulant is urea, Ca(NO 3 ) 2 A mixed solution with agar, in which the concentration of urea is 3mol / L, Ca(NO 3 ) 2 The concentration is 3mol / L, and each liter of mixed solution contains 1.5g of agar powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com