Method for preparation of lignite resin drilling fluid loss additive

A technology of fluid loss reducer and lignite resin, which is applied in the directions of drilling compositions, chemical instruments and methods, etc., can solve the problems of easy foaming, difficult to control reaction and condensation process, and no visibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] 1. Preparation of lignite resin fluid loss additive

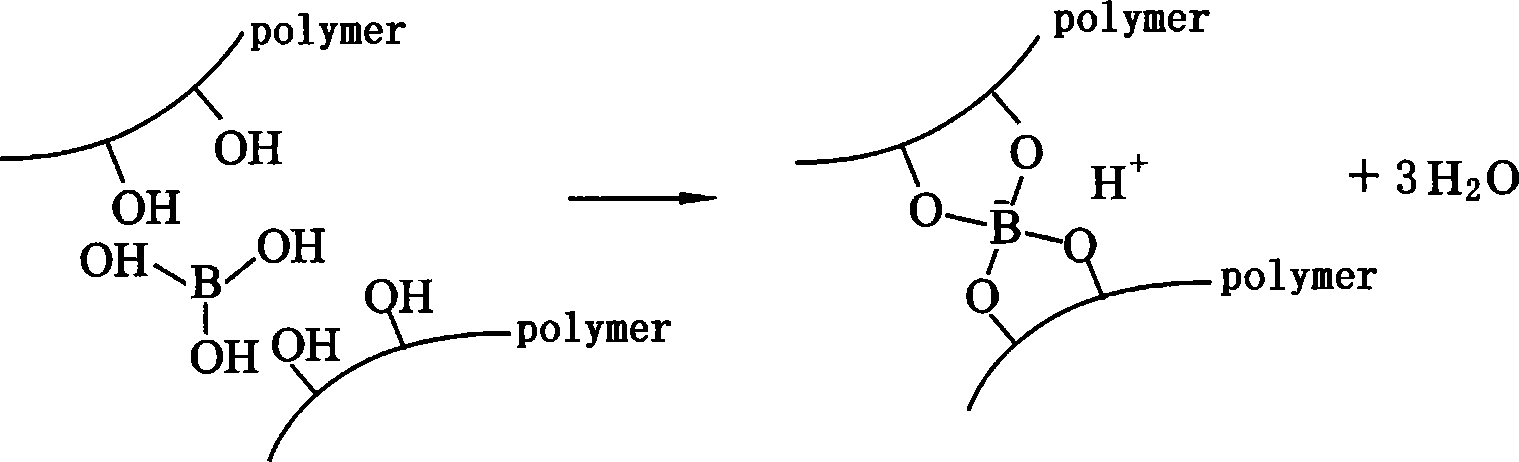

[0032] (1) Add water 50g, lignite 26.5g, acrylic scrap 10.5g, polyether polyol 5.6g, sodium hydroxide 3.2g, potassium hydroxide 4.2g, sodium bisulfite 0.55g, sodium metabisulfite into the reactor in turn 0.55g, boric acid 0.25g, zirconium chloride 0.35g, formaldehyde 0.6g.

[0033] (2) Turn on the stirring device, stir the mixture in the reactor uniformly for 30 minutes, heat the reactor to a temperature of 130°C, react at a constant temperature for 4 hours, stop stirring and heating, and spray dry to obtain a solid powder product of the lignite resin filtrate reducer.

[0034] 2. Performance evaluation of lignite resin filtrate reducer

[0035] (1) Reduce fluid loss and rheology

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com