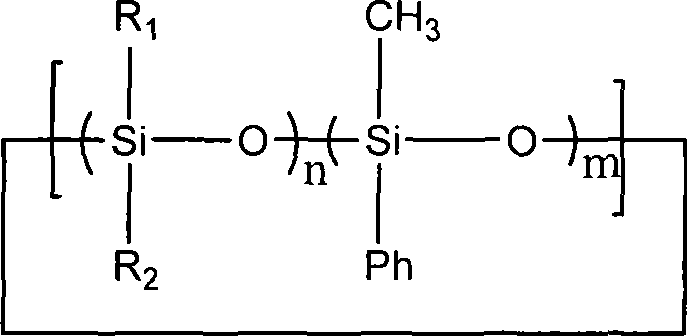

Method for preparing phenyl-containing mixed cyclic siloxane

A technology of phenyltrichlorosilane and methylphenyldichlorosilane is applied in the field of phenyl-containing mixed bad siloxane, can solve the problem of not finding phenyl-containing mixed cyclosiloxane and the like, and achieves low cost and raw materials. Easy-to-obtain, widely-applied effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In a 2000ml three-necked flask equipped with stirring, a thermometer and a dropping funnel, add 510g of water, 100g of gasoline, drop in 387g of dimethyldichlorosilane (dropping time is 2.5h) and 120g of methylbenzene produced by heat shrinkage A mixture of phenyldichlorosilane (the content of phenyltrichlorosilane is 4.0%). The hydrolysis temperature is 30°C. After the dropwise addition is completed, the reaction is continued for 1 h. Leave to layer, wash to neutral. Gasoline was distilled off to obtain 300g colorless and transparent hydrolyzed material with a yield of 98%. The obtained hydrolyzed material was placed in a 500mL device thermometer and a reaction flask of a vacuum distillation device, 7.0g of lithium hydroxide was added, the temperature was raised to 290°C at 10mmHg, and 255g of fractions were collected. The yield was 85.0%. Analyzed by color-mass spectrometry, (Me 2 SiO) n The total content of (MePhSiO) (n=2,3,4,5) is 45%, (Me 2 SiO) n (MePhSiO) ...

Embodiment 2

[0031] In a 2000ml three-necked flask equipped with stirring, a thermometer and a dropping funnel, add 1000g of water, 200g of toluene, drop in 387g of dimethyldichlorosilane (dropping time is 2.0h) and 70g of methylbenzene produced by heat shrinkage A mixture of phenyldichlorosilane (8.0% phenyltrichlorosilane content). The hydrolysis temperature was 70°C. After the dropwise addition was completed, the reaction was continued for 1.5 hours. Leave to layer, wash to neutral. The toluene was evaporated to obtain 258g of colorless and transparent hydrolyzed material with a yield of 95%. The obtained hydrolyzed material was placed in a 500mL device thermometer and a reaction flask of a vacuum distillation device, 5.2g of potassium hydroxide was added, the temperature was raised to 250°C at 5mmHg, and 229g of fractions were collected. The yield was 89%. Analyzed by color-mass spectrometry, (Me 2 SiO) n The total content of (MePhSiO) (n=2,3,4,5) is 38%, (Me 2 SiO) n (MePhSiO) ...

Embodiment 3

[0033] In a 2000ml three-necked flask equipped with stirring, a thermometer and a dropping funnel, add 300g of water, 70g of n-hexane, drop in 387g of dimethyldichlorosilane (dropping time is 3.0h) and 300g of methyl Mixture of phenyldichlorosilane (6.0% phenyltrichlorosilane content). The hydrolysis temperature is 40°C. After the dropwise addition is completed, the reaction is continued for 0.5h. Leave to layer, wash to neutral. The n-hexane was distilled off to obtain 417g of colorless and transparent hydrolyzed material, with a yield of 96%. The obtained hydrolyzed material was placed in a 1000 mL device thermometer and a reaction flask of a vacuum distillation device, 20.0 g of sodium hydroxide was added, the temperature was raised to 290 °C at 20 mmHg, and 379 g of fractions were collected. The yield was 91%. Analyzed by color-mass spectrometry, (Me 2 SiO) n The total content of (MePhSiO) (n=2,3,4) is 8%, (Me 2 SiO) n (MePhSiO) 2 The total content of (n=1,2,3) is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com