Process and device for separation of liquids emulsified in mixtures of liquids and gases dissolved in mixtures of liquids and gases by localized pressure reduction

一种混合物、液体的技术,应用在通过局部减压来分离乳化于液体混合物中的液体和溶解于液气混合物中的气体和装置领域,能够解决建筑和安装成本上升、爆炸、分离慢等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

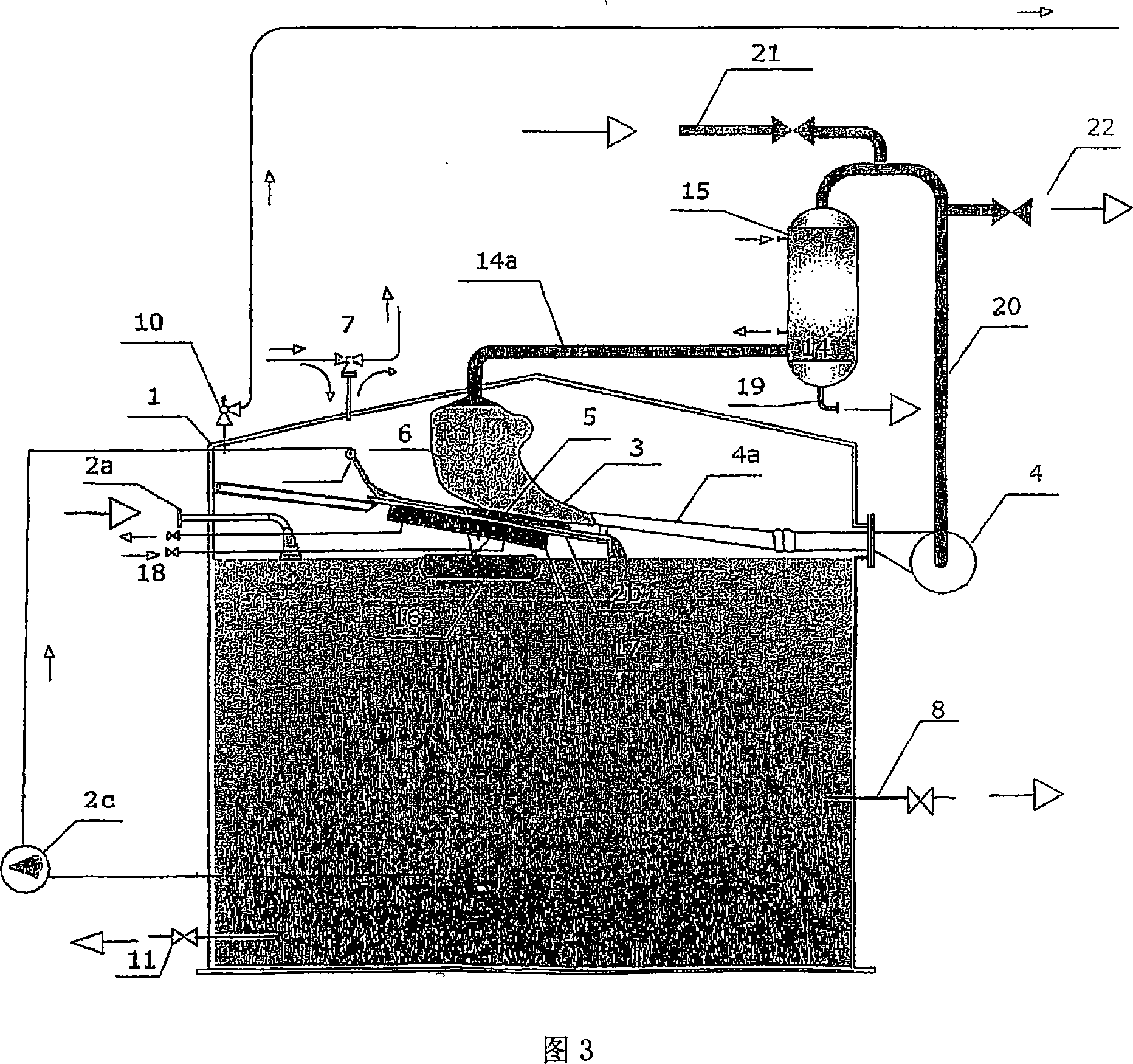

[0026] Fig. 1 has shown a kind of theoretical approach of implementing the method of the present invention, wherein, have the crude oil of emulsified water and dissolved gas, i.e. crude oil 2 to be treated, be imported in the closed treatment tank 1 through input pipe 2a, described crude oil 2 It will be stored in said treatment tank 1 until after treatment, leaving statically or dynamically through the outlet pipe 8 (ie the treated crude oil leaves the tank at the same time as the crude oil 2 enters the tank). The process gas 3 is compressed by a compressor 4, and the process gas stream 3 is injected tangentially onto the free surface of the crude oil by means of an injector 4a, before reaching said surface, said process gas stream 3 forms a specific angle with the free surface of said crude oil , the angle can vary from 0° to 30°, preferably 0-8°, more preferably 5°. In the area of influence of the process gas stream 3 localized areas 5 of pressure reduction are formed on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com