Method for rapidly measuring reinforcing steel tarnishing criticality chlorine ion concentration

A technology of chloride ion concentration and steel bar corrosion, applied in the direction of material electrochemical variables, etc., can solve the problems of real-time monitoring of non-corrodible batteries, long test time, continuous monitoring of non-corrodible batteries, etc., and achieve the effect of reducing the critical concentration measurement time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

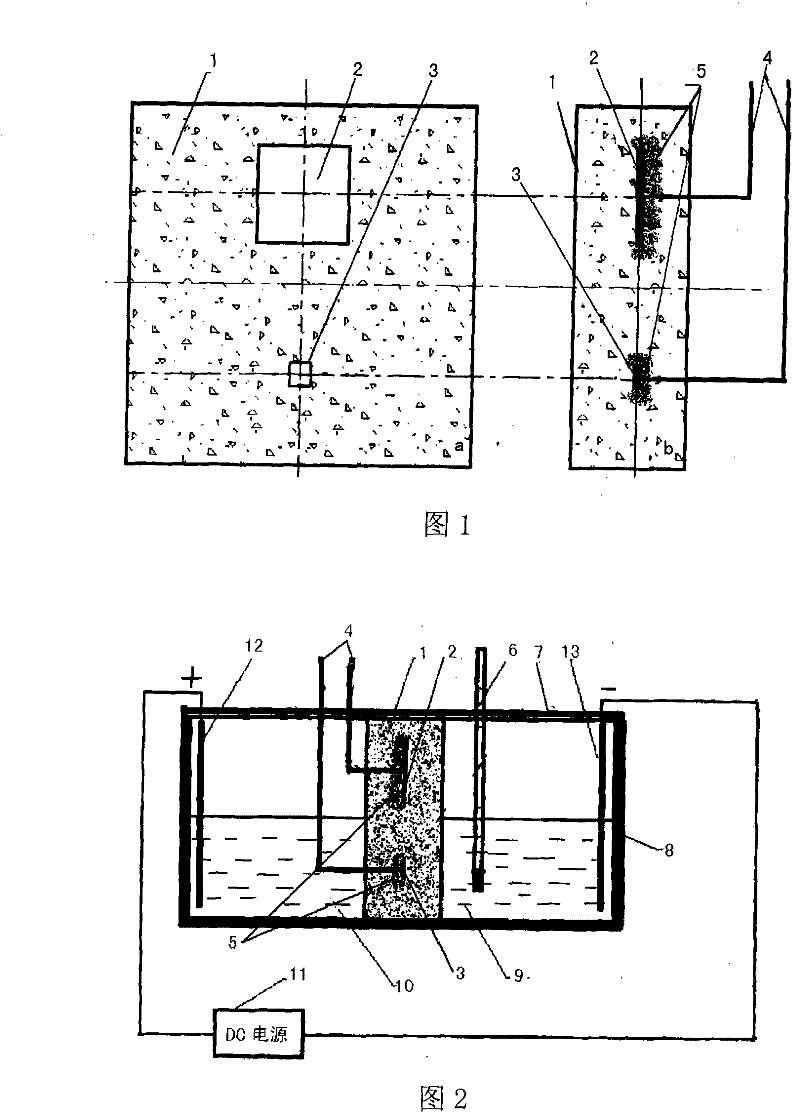

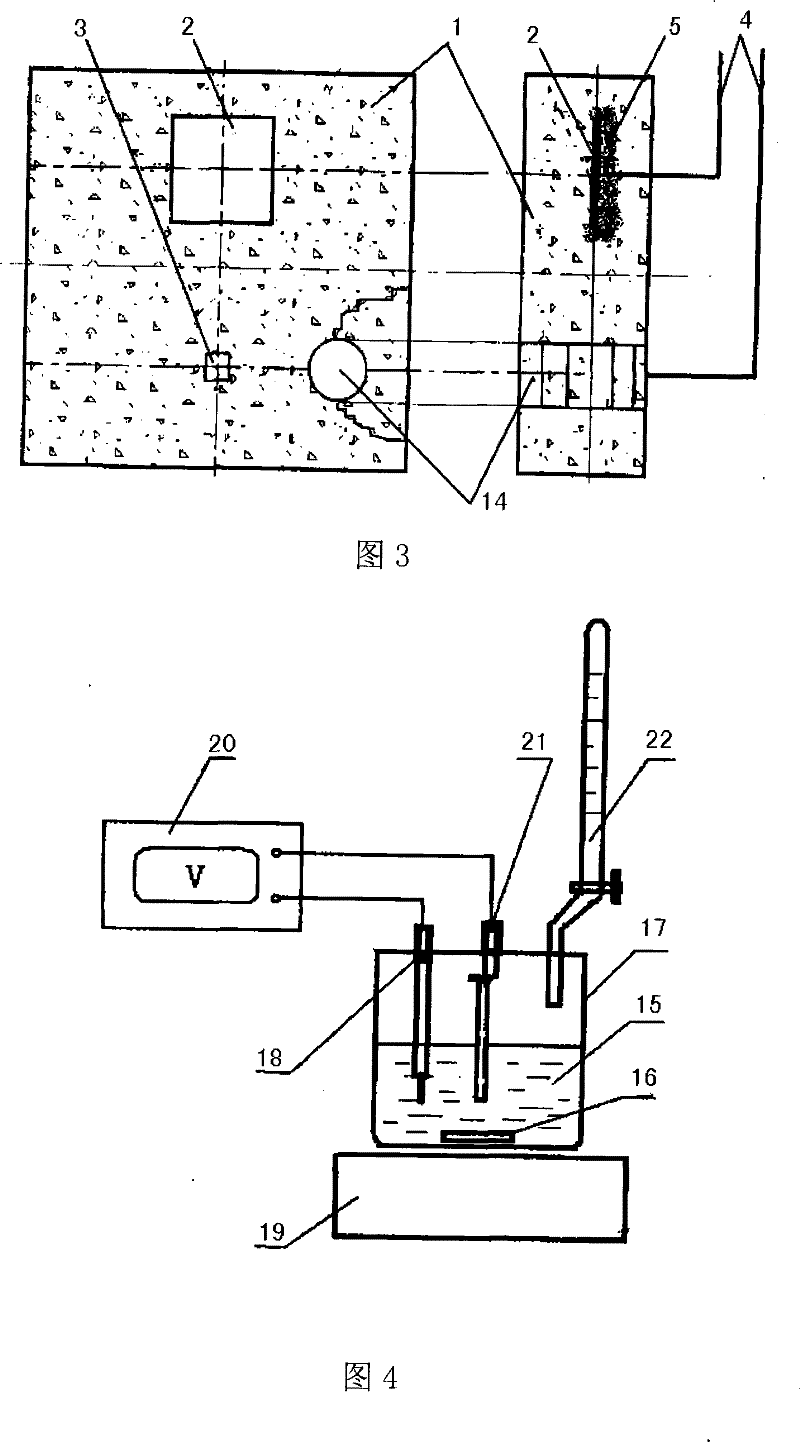

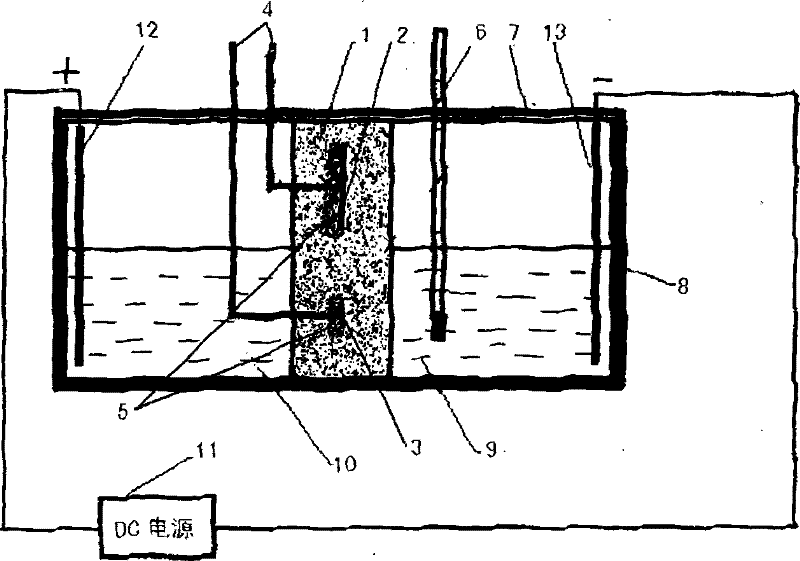

Method used

Image

Examples

Embodiment 1

[0024] In a certain test, the mass of concrete powder obtained by sampling the concrete on the electrode surface was 6.9g, and the concentration of silver nitrate used was C AgNO3 =0.01mol / l, the cement content in the concrete C%=17.58%, and the relationship between the potential measured by titration and the volume of the consumed silver nitrate solution and its primary and secondary derivatives are shown in the following table:

[0025] V AgNO3 Potential difference E / mV ΔE / ΔV(mV / ml) ΔE 2 / ΔV 2 (mV / ml 2 ) 0.0 211.0 2.0 221.0 5 4.0 248.4 13.7 4.35 5.5 281.8 22.3 5.73 6.0 289.3 15.0 -14.6 8.0 312.5 11.6 -1.7 10.0 321.6 4.5 -14.2

[0026] Calculate ΔE corresponding to the second-level derivative by interpolation 2 / ΔV 2 V at zero AgNO3 value

[0027] V AgNO 3 = 5.5 mL + 0.5 mL X ( 5.73 mV / ml 2 5.73 mV / ml 2 + 14.6 mV / ml 2 ) = 5.64 mL

[0028] According to f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com