Vertical barrel pocket type extraction pump

A condensate pump and vertical cylinder technology, applied in the field of water pumps, can solve the problems of increasing hydraulic loss and volume loss, disturbing the flow state of the impeller inlet, and the overall cantilever length of the pump, so as to reduce hydraulic loss and volume loss, and improve anti-cavitation. Excellent performance and hydraulic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

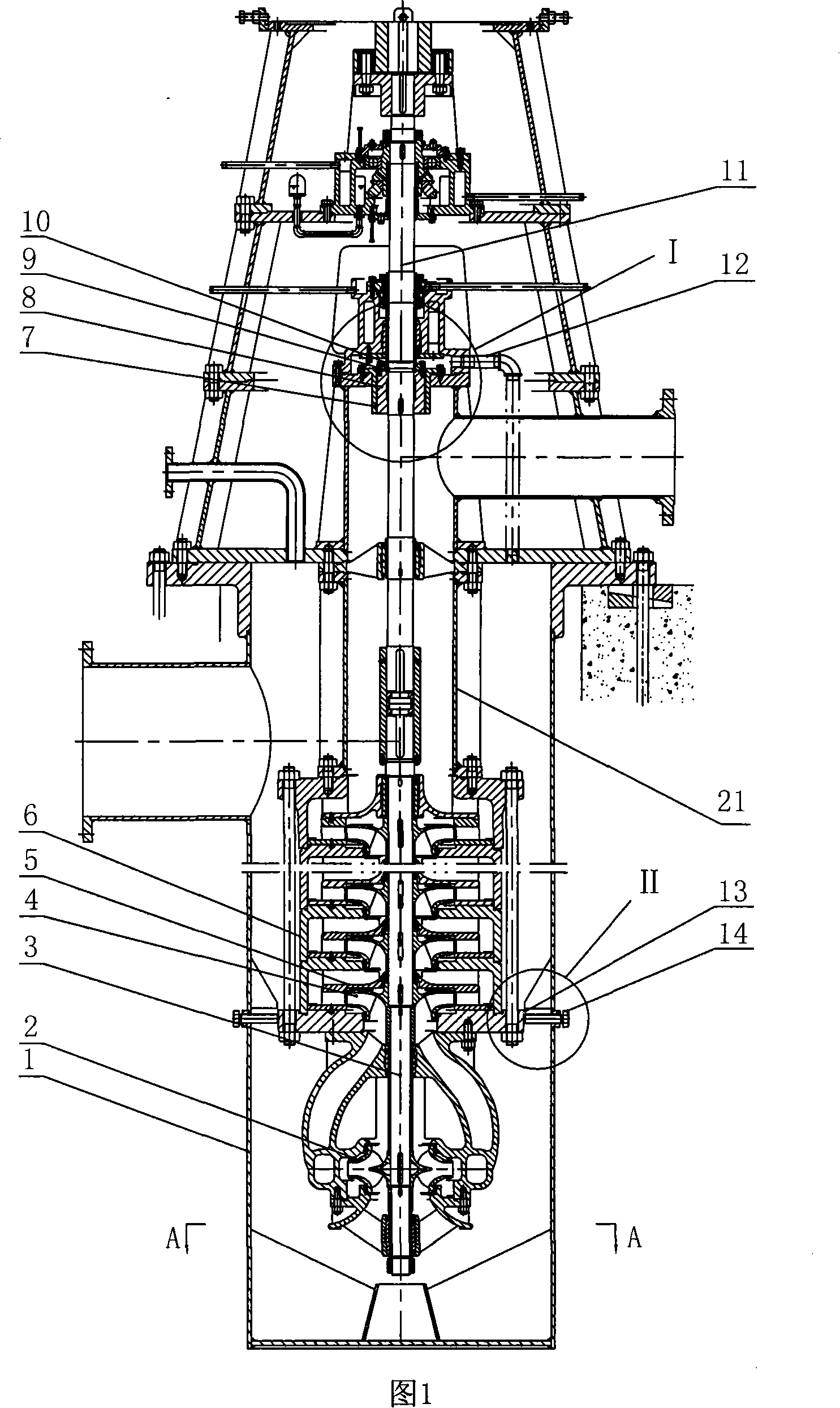

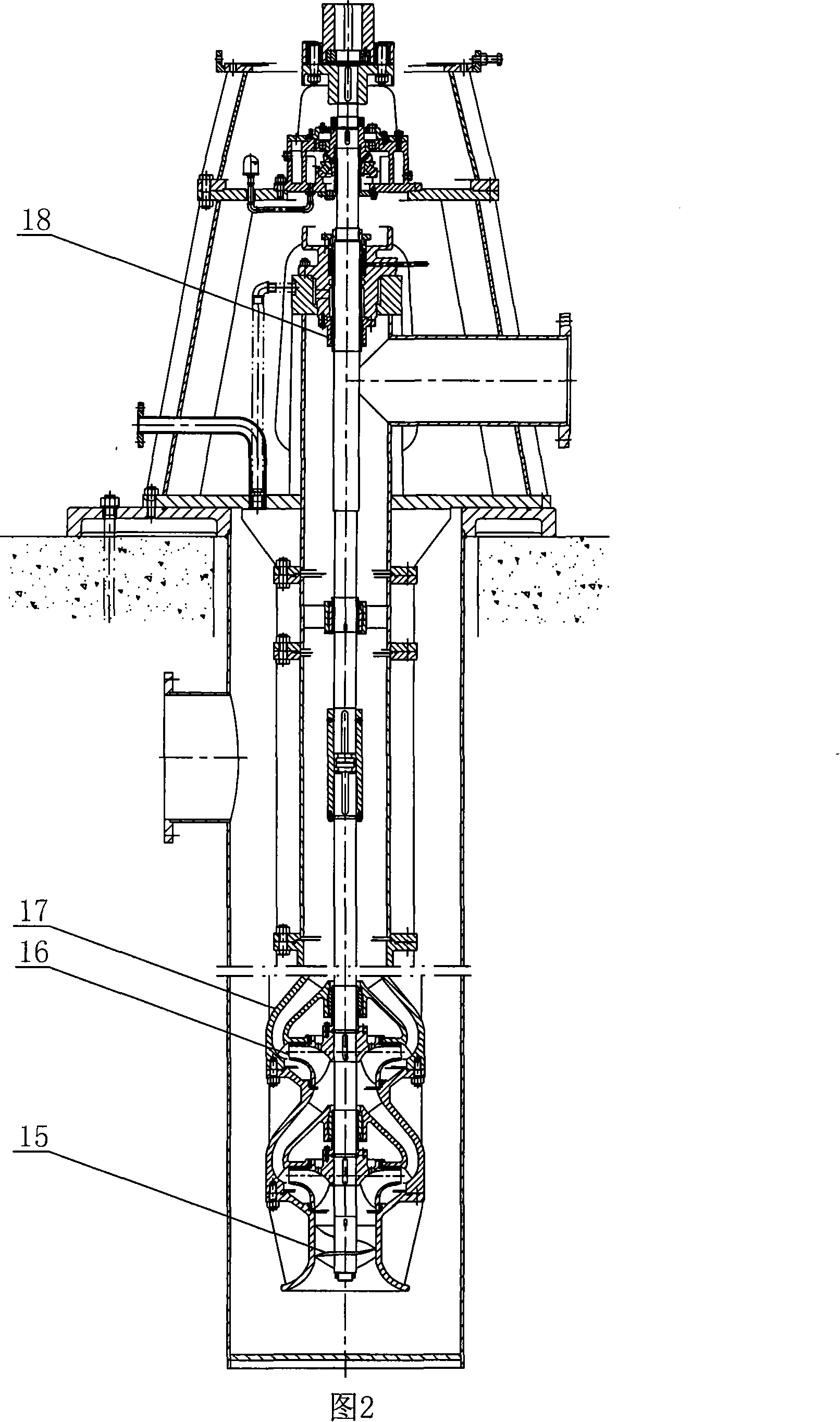

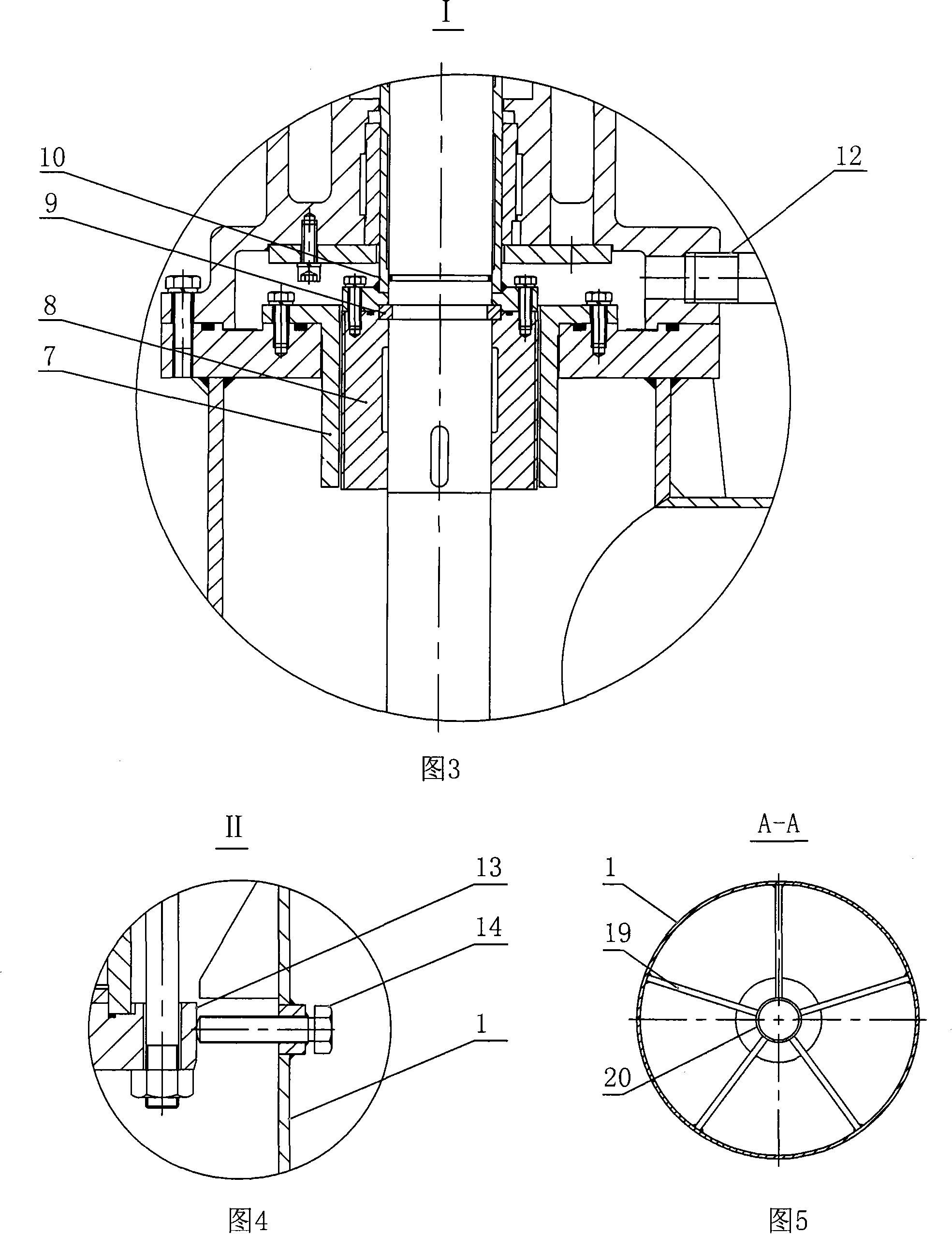

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Referring to Fig. 1, Fig. 3, Fig. 4 and Fig. 5, the first-stage impeller is a double-suction impeller 2, the impeller 4 is a closed structure, the guide vane is a radial guide vane 5, and the radial guide vane 5 is installed in the middle section 6 A balance drum 8 integrated with the upper shaft sleeve 10 is installed on the upper main shaft 11, and a balance drum sleeve 7 with a narrow gap between the balance drum 8 and the balance drum 8 is installed on the inner cylinder 21. The cavity communicates with the outer cylinder 1 through the balance pipe 12, and the deflector 19 and the deflector cone 20 are installed on the bottom of the outer cylinder 1 corresponding to the double-suction impeller 2. set screw 14.

[0021] Referring to FIG. 1 , the first-stage impeller is a double-suction impeller 2 installed on the lower main shaft 3 ....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com