Method for promoting electrostatic charge dissipation on semiconductor chip

An electrostatic charge and semiconductor technology, applied in the field of semiconductor wafer production, can solve problems such as the inability to take out the wafer smoothly, secondary damage to the wafer surface, damage to the thimble and the manipulator, etc., to shorten the dissipation time, promote dissipation, and increase productivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

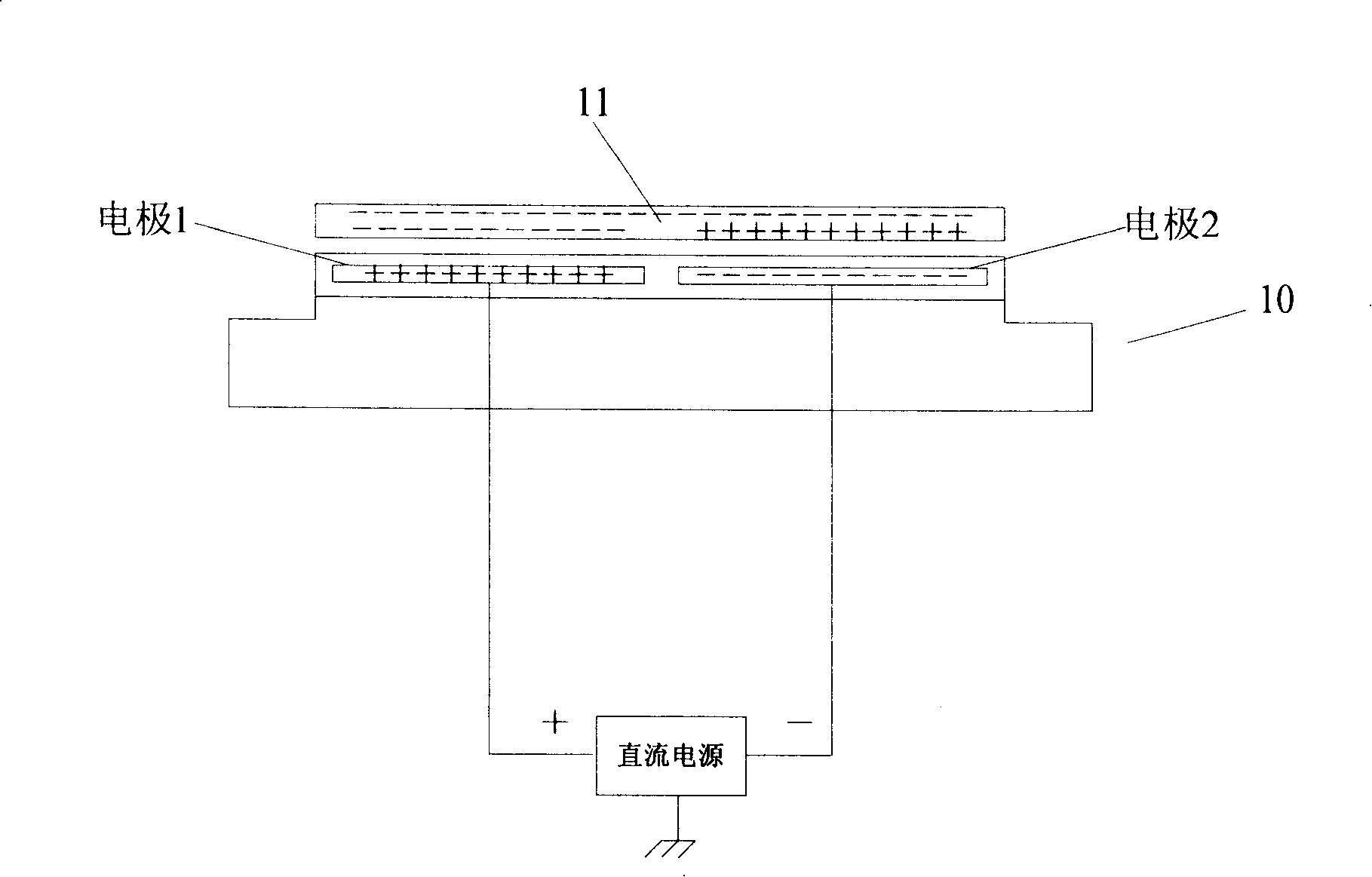

[0031] Embodiment 1: What provide electric potential for two electrodes on the double-electrode electrostatic chuck 10 are two DC power supplies whose output can be switched positive and negative, such as figure 2 As shown, the two DC power supplies are connected in series, and each has an output terminal connected to the electrode.

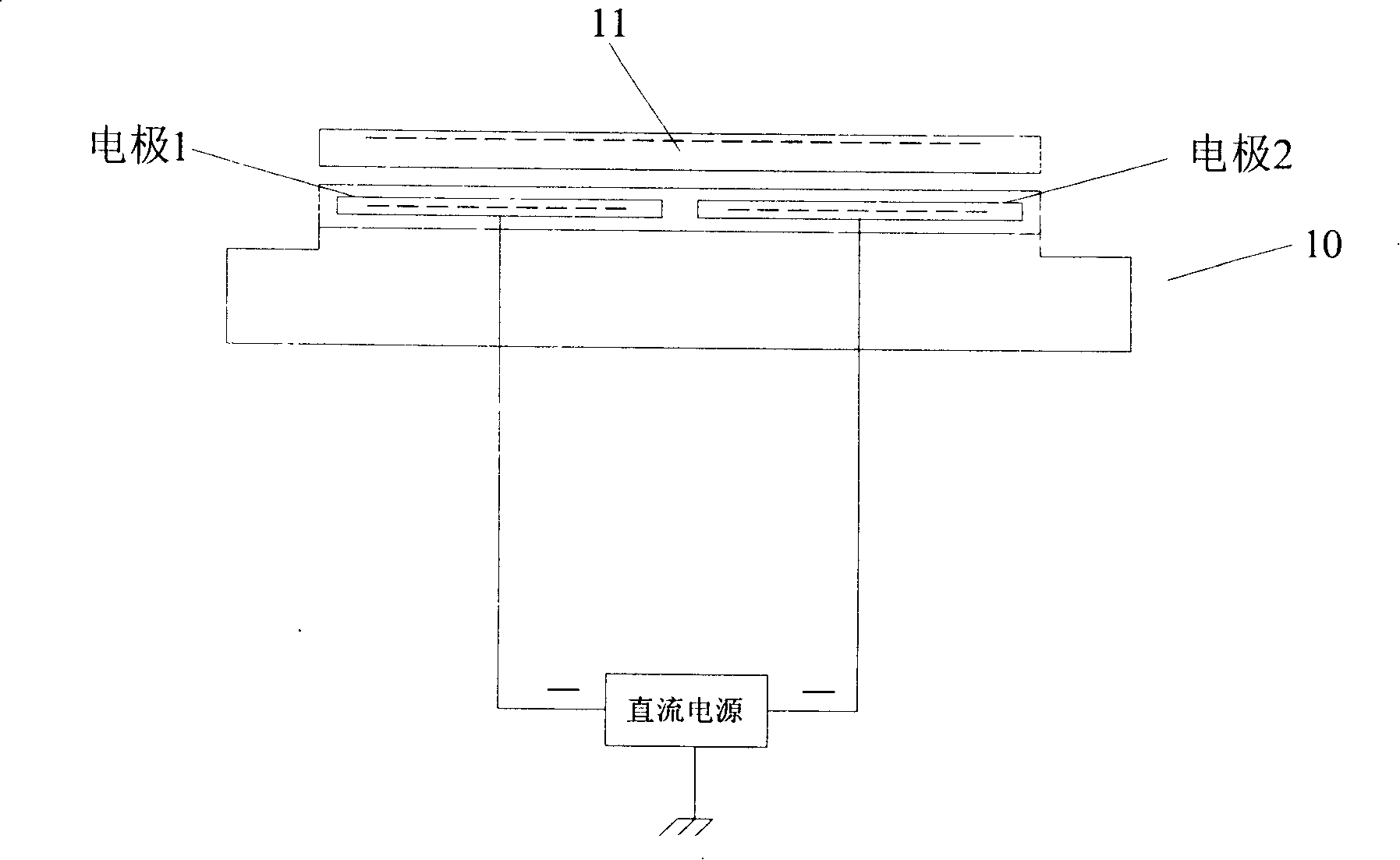

[0032] Such as Figure 4 Shown is the operation flow for releasing a semiconductor wafer from a two-electrode electrostatic chuck. First, in the process, let the electrode 1 of the two-electrode electrostatic chuck 10 be at a positive potential, and the electrode 2 be at a negative potential, and the semiconductor wafer 11 will be attracted on the surface of the two-electrode electrostatic chuck 10, thereby the semiconductor wafer is carried out correspondingly. Process processing or transmission; when the semiconductor wafer starts to be released, change the output polarity of the two DC power supplies, so that the electrode 1 of the double-el...

Embodiment 2

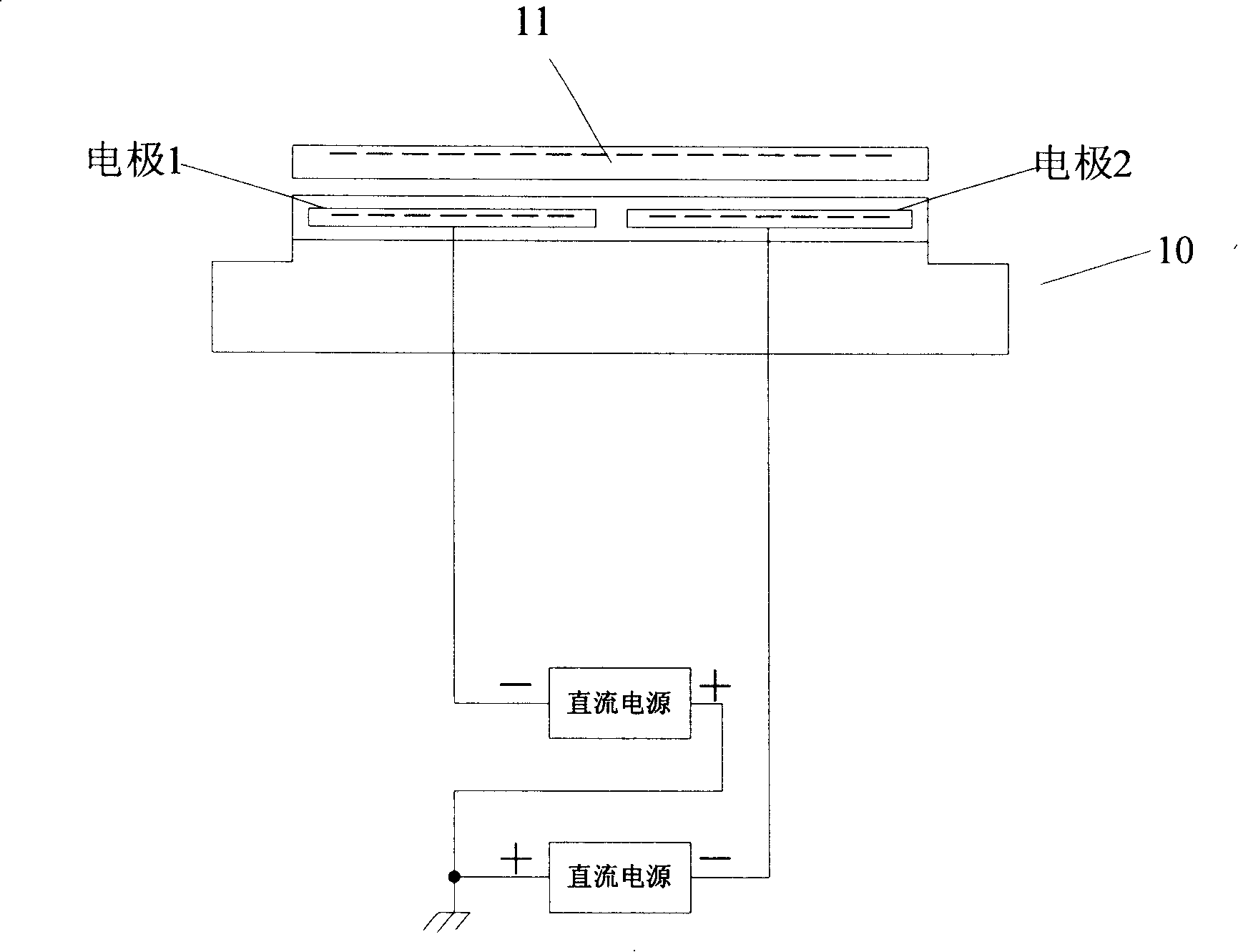

[0036] Embodiment 2: It is a DC power supply whose output can be positive and negative exchanged for the two electrodes on the double-electrode electrostatic chuck 10 to provide potential, such as image 3 As shown, the outputs at both ends are connected to the two electrodes respectively.

[0037] Such as Figure 4Shown is the operation flow for releasing a semiconductor wafer from a two-electrode electrostatic chuck. First, in the process, let the electrode 1 of the two-electrode electrostatic chuck 10 be at a positive potential, and the electrode 2 be at a negative potential, and the semiconductor wafer 11 will be attracted on the surface of the two-electrode electrostatic chuck 10, thereby the semiconductor wafer is carried out correspondingly. Process processing or transmission; when the semiconductor wafer starts to be released, change the output polarity of the DC power supply, so that the electrode 1 of the double-electrode electrostatic chuck is at a negative potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com