Method for manufacturing bismuth sodium titanate-barium titanate ferro-electricity single crystal

A bismuth sodium titanate, ferroelectric single crystal technology, applied in the direction of single crystal growth, single crystal growth, chemical instruments and methods, etc., can solve the problems of small crystal size, difficulty in practical application, and large number of nucleation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

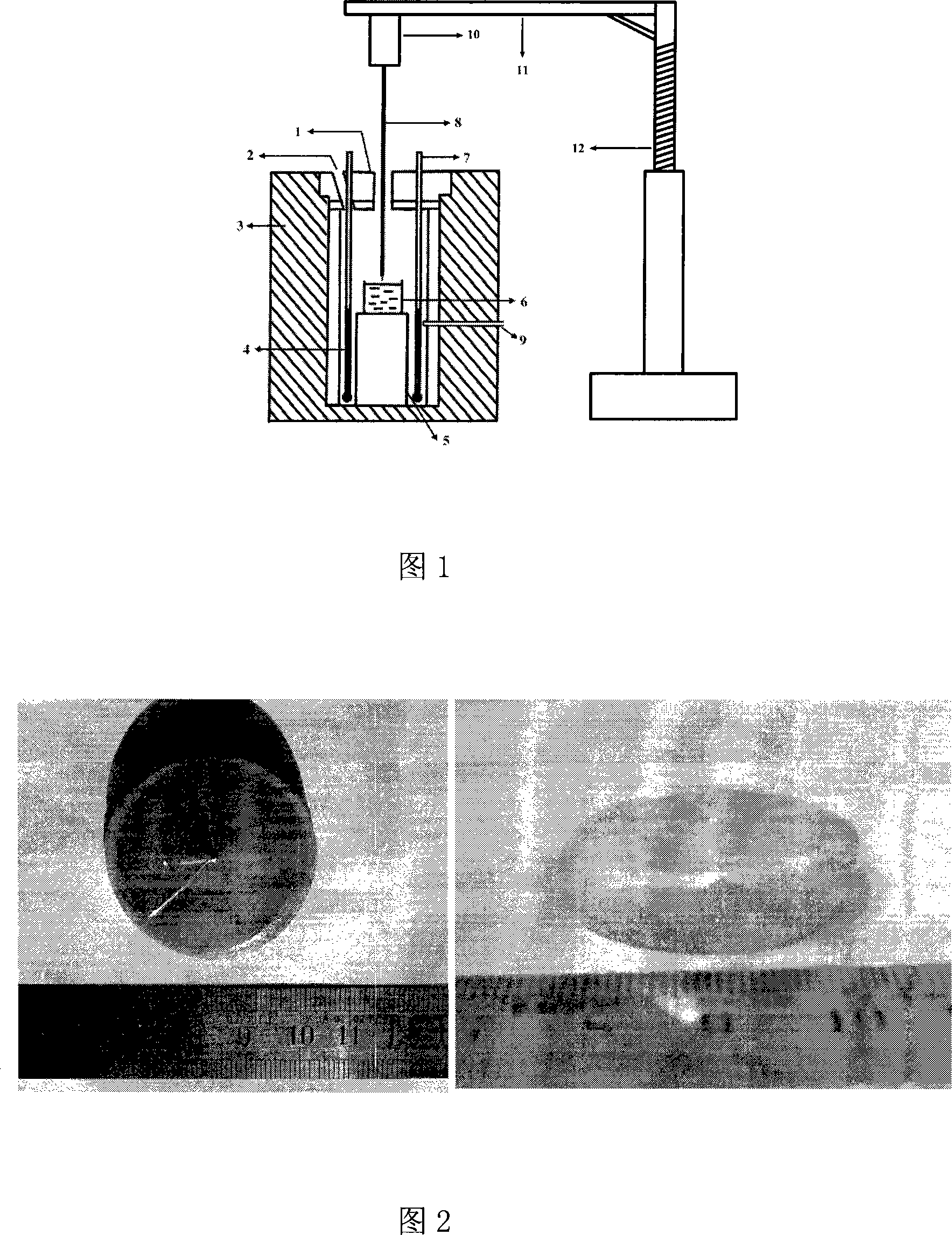

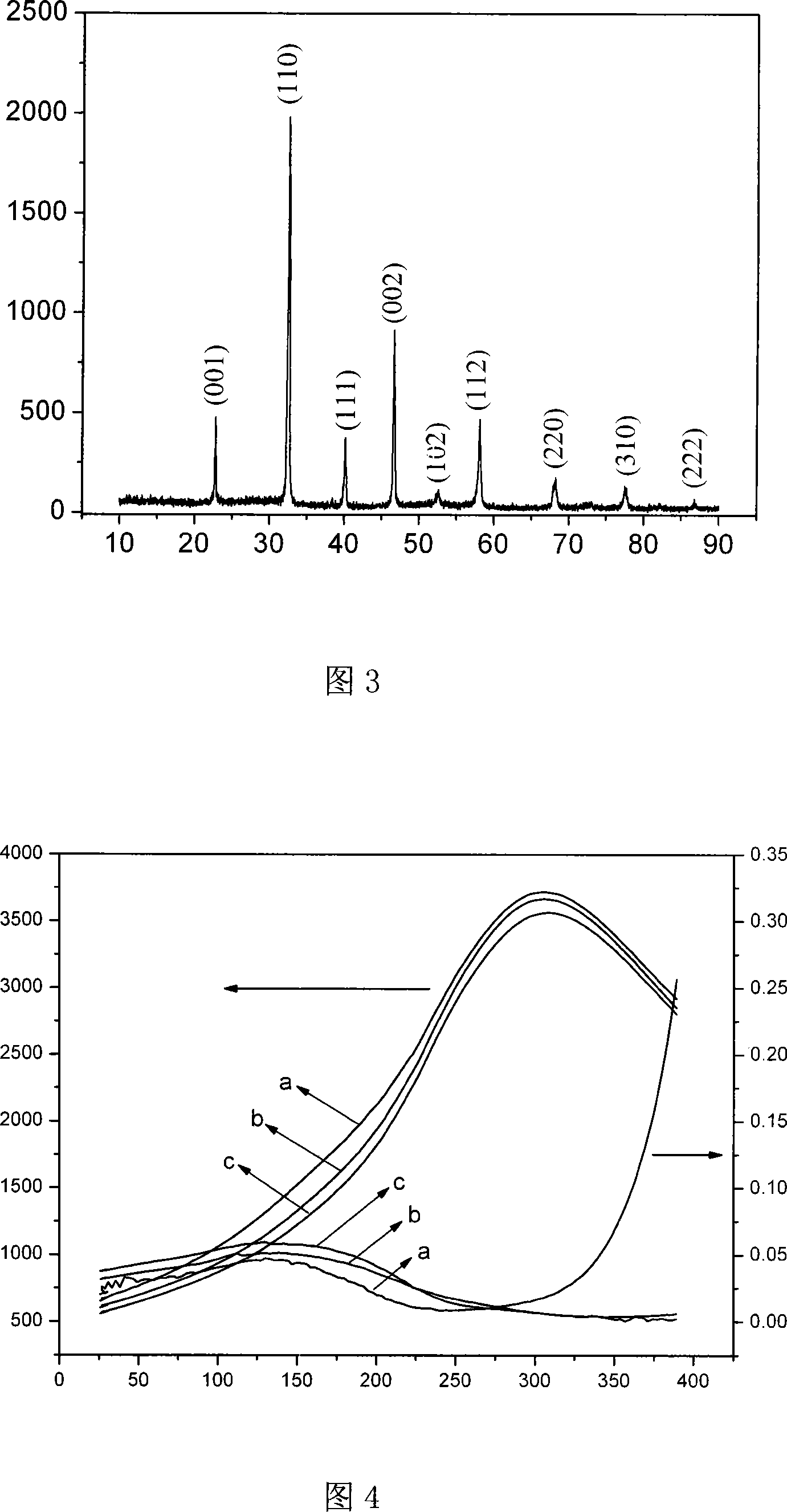

[0033] Sodium carbonate, bismuth oxide, titanium dioxide and barium carbonate with a purity of 99.99% are dried according to 0.94Na 0.5 Bi 0.5 TiO 3 -0.06BaTiO 3 The chemical composition ratio was mixed and ball milled for 100 hours, then placed in a covered platinum crucible and heat-treated at 1200°C for 20 hours. Then the resulting product is finely ground and sieved, and a certain proportion of sodium carbonate and bismuth oxide is added as a flux based on the total amount of polycrystalline raw materials, and the molar ratio is Na 2 CO 3 : Bi 2 o3 : 0.94NBT-0.06BT is equal to 5:5:100, and placed in a covered platinum crucible again for heat treatment at 1200°C for 20 hours. Finally, the product is pulverized, finely ground, sieved, and pressed into blocks by cold isostatic pressing. The raw materials pressed into blocks are loaded into a platinum growth crucible, and the growth crucible is placed in the growth furnace shown in FIG. 1 . Raise the temperature to comp...

Embodiment 2

[0035] Sodium carbonate, bismuth oxide, titanium dioxide and barium carbonate with a purity of 99.99% are dried according to 0.90Na 0.5 Bi 0.5 TiO 3 -0.10BaTiO 3 The stoichiometric ratio is weighed, and then additional sodium carbonate and bismuth oxide are weighed as flux, so that Na 2 CO 3 : Bi 2 o 3 : The molar ratio of 0.90NBT-0.10BT is equal to 10:10:100, mixed and ball milled for 100 hours, placed in a covered platinum crucible and heat treated at 1200°C for 20 hours. The resulting product is then finely ground, sieved, and cold isostatically pressed into blocks. The raw materials pressed into blocks are loaded into a platinum growth crucible, and the growth crucible is placed in the growth furnace shown in FIG. 1 . Raise the temperature to completely melt the raw materials, then overheat to 100°C, and keep the temperature for 5 hours, so that the high-temperature solution is fully convected and mixed evenly. Slowly lower the temperature to the solution saturatio...

Embodiment 3

[0037] Sodium carbonate, bismuth oxide, titanium dioxide and barium carbonate with a purity of 99.99% are dried according to 0.85Na 0.5 Bi 0.5 TiO 3 -0.15BaTiO 3 The stoichiometric ratio is weighed, and then additional sodium carbonate and bismuth oxide are weighed as flux, so that Na 2 CO 3 : Bi 2 o 3 : The molar ratio of 0.85NBT-0.15BT is equal to 30:30:100, and the weighed raw materials are put into the platinum growth crucible, and the growth crucible is then placed in the growth furnace shown in FIG. 1 . Raise the temperature to completely melt the raw materials, then overheat to 100°C, and keep the temperature for 5 hours, so that the high-temperature solution is fully convected and mixed evenly. Slowly lower the temperature to the solution saturation point temperature, use platinum wire as the seed crystal, and select the appropriate pulling speed and rotation speed for NBBT crystal growth. During the crystal growth process, the temperature was lowered at a cooli...

PUM

| Property | Measurement | Unit |

|---|---|---|

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

| piezoelectric charge coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com