Method for manufacturing gallium nitride nano-wire with tungsten auxiliary heat anneal

A technology of nanowires and auxiliary heat, applied in gaseous chemical plating, semiconductor/solid-state device manufacturing, ion implantation plating, etc., can solve the problems of high requirements for gas path structure and experimental equipment, and achieve the effect of low preparation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

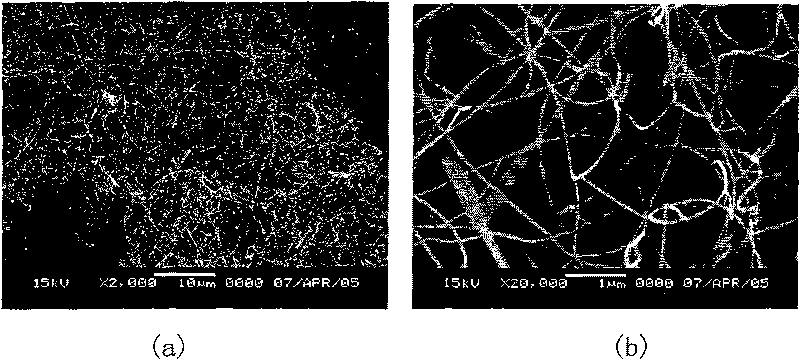

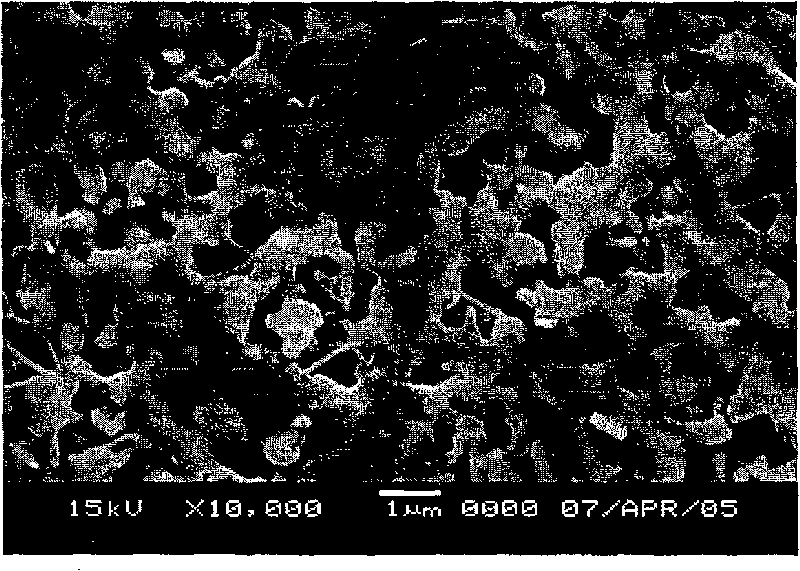

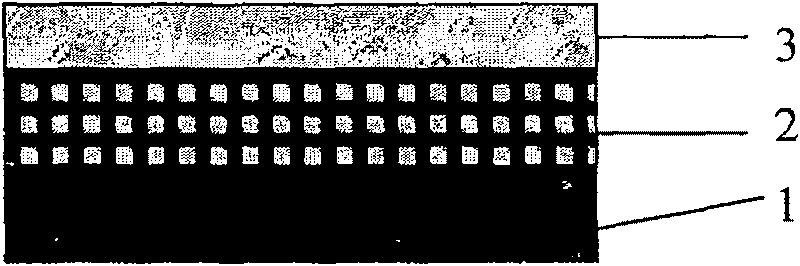

[0022] Embodiment 1: adopt MOCVD method in Al 2 o 3 A GaN film with a thickness of 2 microns was epitaxially grown on the substrate, and this film was used as a template, and an 8nm thick metal W thin layer was deposited on the template at a temperature of 500°C by electron beam evaporation, and then the metal layer with the metal layer The template is put into the thermal annealing reaction chamber, under N 2 The atmosphere was heated up to 1050°C and annealed for 20 minutes. The sample measurement results show that the GaN nanowires grown by this method have a diameter between 10 and 100 nm and a high aspect ratio.

Embodiment 2

[0023] Embodiment 2: The same result can be obtained by using the method as in Embodiment 1 with SiC, Si or GaAs as the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com